A preparation method and application of a carbon-wrapped porous cobaltous oxide nanomaterial with a shell-core structure

A technology of cobaltous oxide nanometer and cobalt trioxide nanometer, which is applied in the preparation and application field of carbon-wrapped porous cobaltous oxide nanomaterial with shell-core structure, to achieve the effect of improving the transmission path, simple preparation process and improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

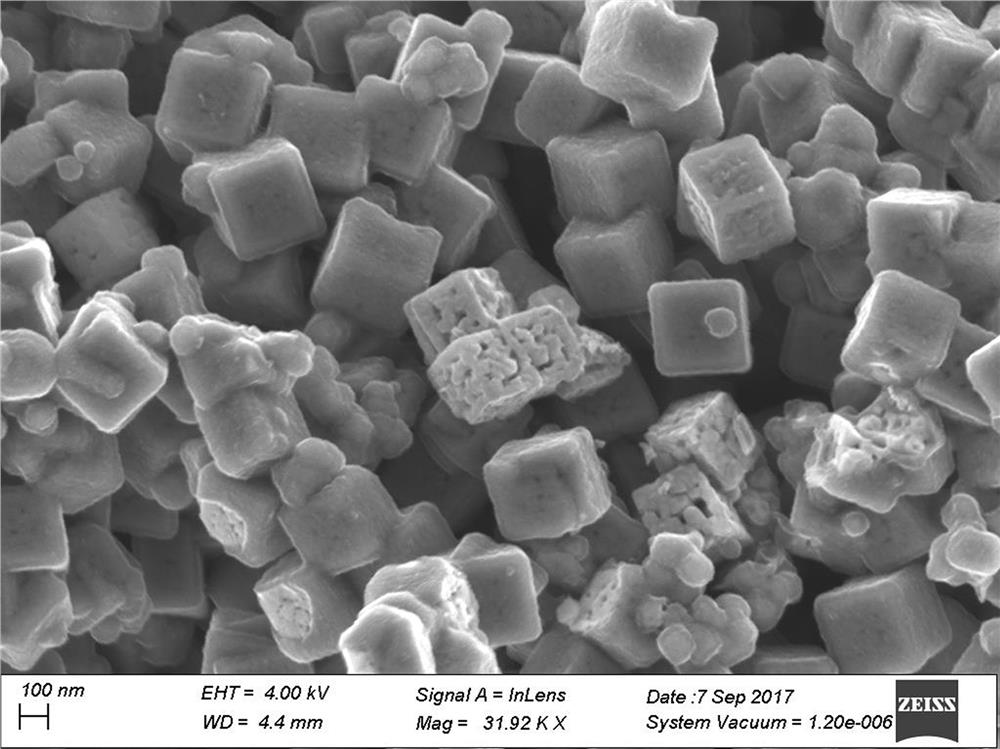

[0031] In this embodiment, the preparation steps of carbon-wrapped porous cobaltous oxide nanomaterials with a shell-core structure are as follows:

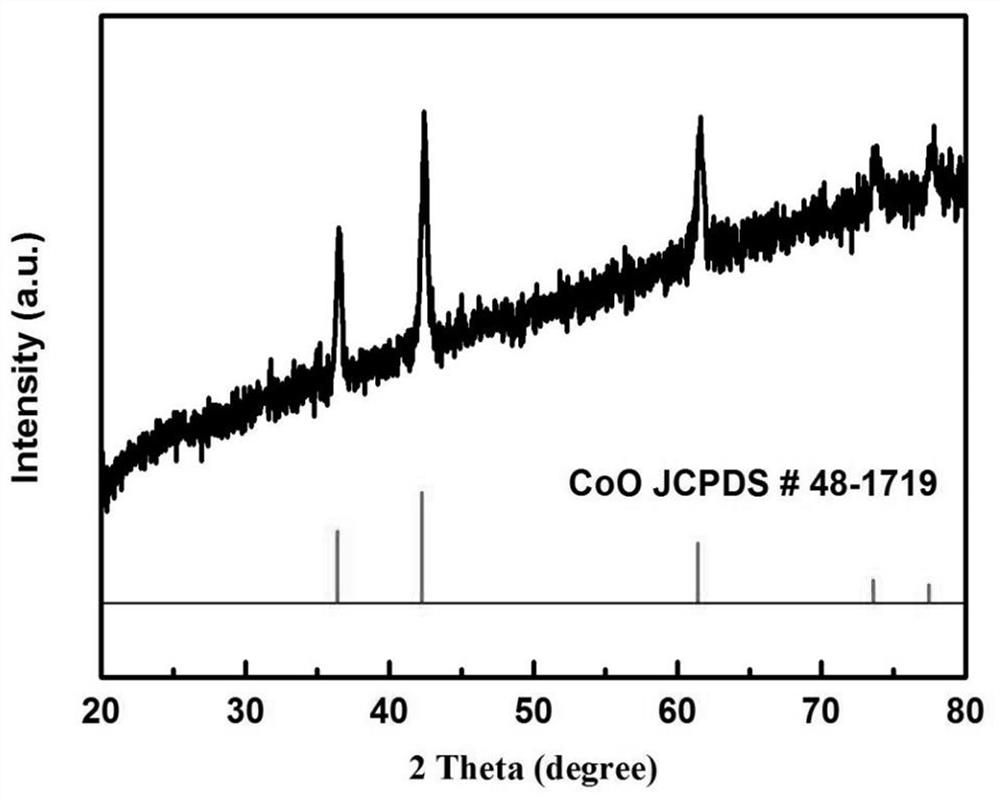

[0032] The first step, preparation of cobalt trioxide nanocubes

[0033] The hydrothermal method (also known as the hydrothermal method) was used to prepare cobalt tetroxide, and 0.04 mol of cobalt nitrate hexahydrate was dispersed in 40 mL of deionized water, and stirred until transparent under magnetic stirring; then 0.01 mol of sodium hydroxide was added to the above solution to continue Stir until a clear solution is obtained; transfer the above solution to a 50 mL polytetrafluoroethylene reactor, and place it in an oven at 180 °C for 24 h; after the reaction, the reactor is naturally cooled to room temperature, and the obtained sample is centrifuged Separated, washed three times by centrifugation with water / ethanol mixed solution, and dried at 65°C for 12 h;

[0034] The second step, preparation of PDA (polydopamine)-wrappe...

Embodiment 2

[0040] Same as Example 1, the difference is,

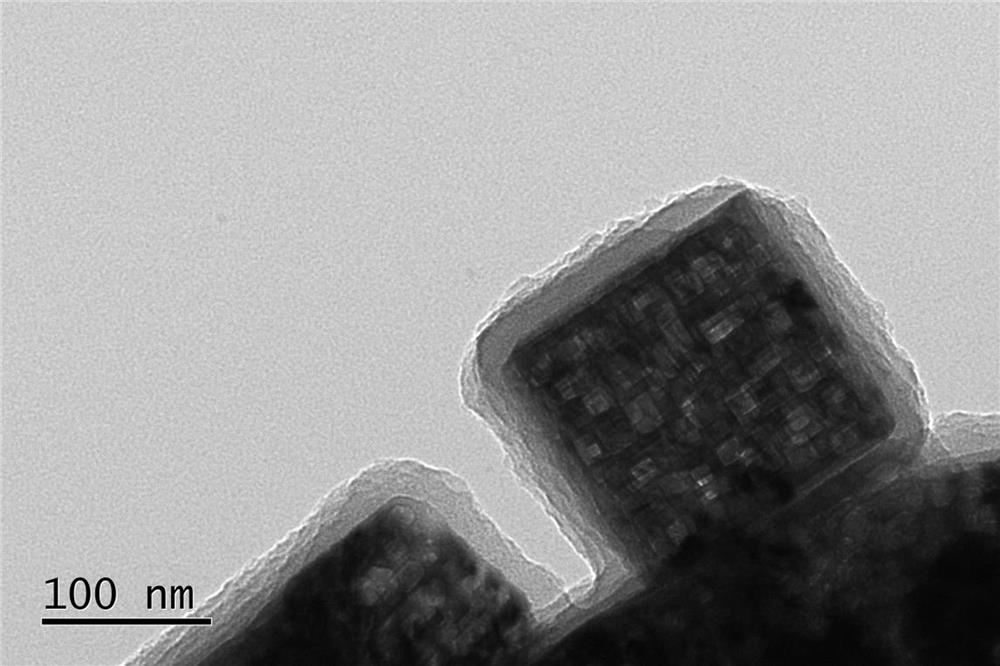

[0041] The fourth step, preparation of porous carbon-coated cobaltous oxide etched by hydrochloric acid

[0042] The product prepared in the third step was dispersed in a hydrochloric acid solution with a concentration of 0.1 mol / L and etched for 3 minutes, then soaked in deionized water / ethanol to remove soluble impurities, and the obtained material was vacuum-dried at 65°C after centrifugation , and a carbon-wrapped porous cobaltous oxide nanocube three-dimensional material with a shell-core structure was prepared.

[0043] The transmission electron microscope image of the carbon-wrapped porous cobaltous oxide nanocube three-dimensional material etched by hydrochloric acid in this embodiment is as follows Figure 4 shown.

Embodiment 3

[0045] Same as Example 1, the difference is,

[0046] The fourth step, preparation of porous carbon-coated cobaltous oxide etched by hydrochloric acid

[0047] The product prepared in the third step was dispersed in a hydrochloric acid solution with a concentration of 0.1 mol / L and etched for 6 min, then soaked in deionized water / ethanol to remove soluble impurities, and the obtained material was vacuum-dried at 65°C after centrifugation , and a carbon-wrapped porous cobaltous oxide nanocube three-dimensional material with a shell-core structure was prepared.

[0048] The transmission electron microscope image of the carbon-wrapped porous cobaltous oxide nanocube three-dimensional material etched by hydrochloric acid in this embodiment is as follows Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com