Preparation method of delicious health potato chip

A production method and healthy technology, which can be applied to the functions of food ingredients, food ingredients as taste improvers, food ingredients as taste improvers, etc., can solve problems such as inability to effectively avoid acrylamide, human health damage, and reproductive development. Achieve the effect of improving sensory attributes and edible health, improving health attributes, color protection and starch protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

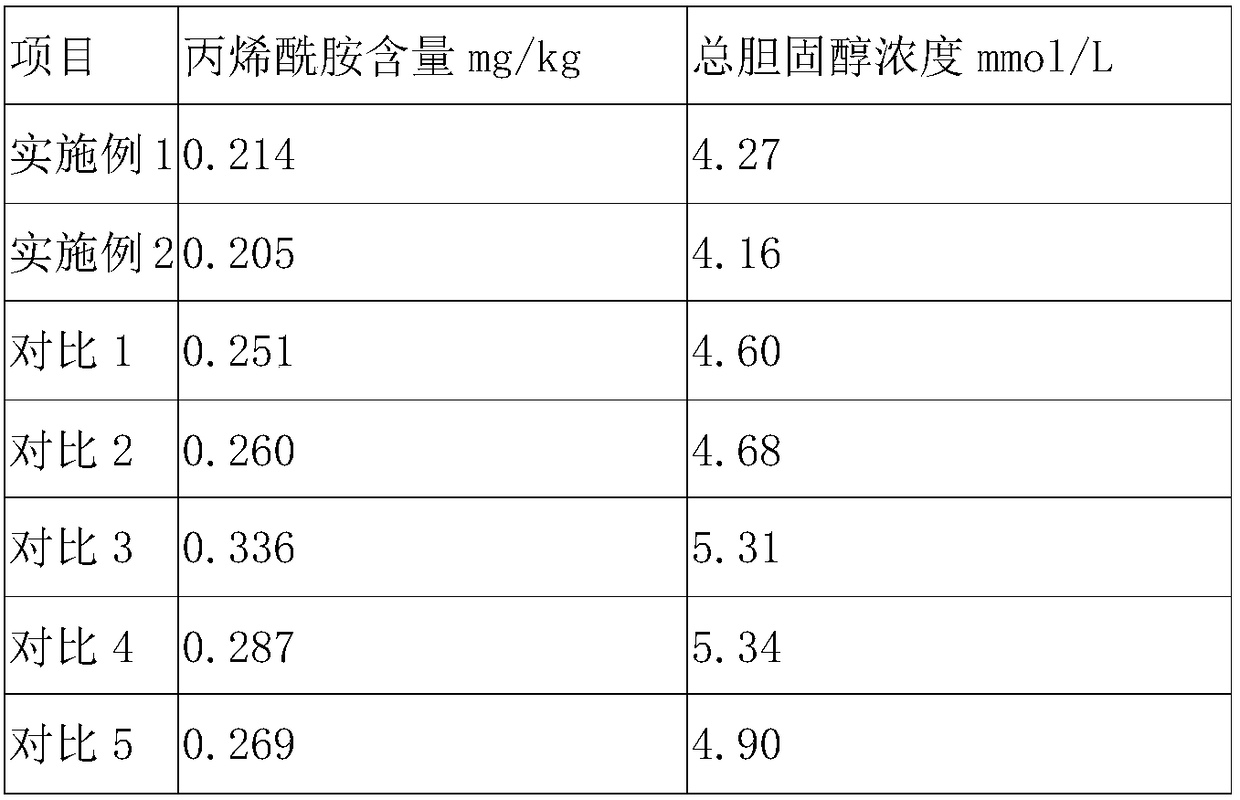

Examples

Embodiment 1

[0020] A method for making delicious and healthy potato chips, comprising the following steps:

[0021] (1) Pretreatment: preferably undamaged and non-germinated potatoes are used as raw materials, put them in a steamer to cook for 33 minutes after removing impurities such as soil with clean water, and slice to obtain potato slices after cooling and peeling;

[0022] (2) Enzymolysis: first immerse the potato slices in clean water and oscillate for 27 minutes with a frequency of 22kHz ultrasonic wave, then add a mixed enzyme agent with a mass of 0.7% of the mass of potato slices to it, pump it up to 43°C for 2.5 hours, take it out and drain Dry water to obtain enzymatic hydrolysis potato chips, through ultrasonic oscillation and enzymatic hydrolysis methods can reduce the starch content in potato chips and reduce the production of acrylamide during frying;

[0023] (3) Production of fermented liquid: Weigh 12.4 parts of Dendrobium candidum, 7.1 parts of Humulus japonicus, 56 pa...

Embodiment 2

[0031] (1) Pretreatment: Potatoes with no damage and no germination are preferred as raw materials. After removing impurities such as soil with clean water, put them in a steamer and cook for 38 minutes. After cooling and peeling, slice them to obtain potato chips;

[0032] (2) Enzymolysis: first immerse the potato slices in clean water and oscillate for 29 minutes with a frequency of 23kHz ultrasonic wave, then add a mixed enzyme agent of 0.9% of the mass of the potato slices to it, pump it up to a vacuum and heat it up to 44°C for 3 hours, take it out and drain it Enzymatic hydrolysis of potato chips with water, through ultrasonic oscillation and enzymatic hydrolysis methods can reduce the starch content in potato chips and reduce the production of acrylamide during frying;

[0033] (3) Production of fermented liquid: Weigh 13.6 parts of Dendrobium officinale, 8.5 parts of Humulus japonicus, 7 parts of spinach, 5.4 parts of lemon leaves and 4 parts of olive leaves according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com