Preparation method of composite material composited by rags and resin

A technology of composite materials and resin compounding, applied in the field of composite materials, can solve the problems of environmental degradation and less natural materials, and achieve the effects of increasing impact resistance, preventing agglomeration, and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

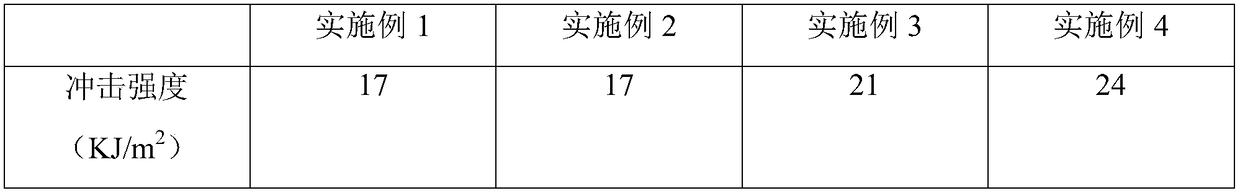

Examples

Embodiment 1

[0031] A preparation method of a composite material composed of rags and resin, comprising the steps of:

[0032] (1) 3 parts by weight of carboxymethyl cellulose, 3 parts by weight of starch, 3 parts by weight of polyvinyl alcohol, 3 parts by weight of dextrin, 0.7 parts by weight of alumina, 0.4 parts by weight of silicon oxide, 0.6 parts by weight of magnesium oxide, 0.5 parts by weight of Parts by weight of chromium oxide are placed in 17 parts by weight of deionized water, and stirred evenly to obtain an impregnation solution;

[0033] (2) Arrange 10 parts by weight of crushed powder in the impregnation solution, stir at a speed of 50 r / min for 30 minutes; bake at a temperature of 900°C for 2 hours, and then cool down to room temperature to obtain granular materials;

[0034] The cooling process is:

[0035] a. Cool down to 700°C at a cooling rate of 10°C per minute, and keep warm for 15 minutes at this temperature;

[0036] b. Cool down to 500°C at a cooling rate of 15...

Embodiment 2

[0048] A preparation method of a composite material composed of rags and resin, comprising the steps of:

[0049] (1) 1 weight part of carboxymethyl cellulose, 1 weight part of starch, 1 weight part of polyvinyl alcohol, 1 weight part of dextrin, 0.5 weight part of alumina, 0.1 weight part of silicon oxide, 0.2 weight part of magnesium oxide, 0.1 Parts by weight of chromium oxide are placed in 12 parts by weight of deionized water, and stirred evenly to obtain an impregnation solution;

[0050] (2) Arrange 5 parts by weight of crushed powder in the impregnation solution, stir at a speed of 50 r / min for 30 min; roast at a temperature of 900° C. for 2 h, and then cool down to room temperature to obtain granular materials;

[0051] The cooling process is:

[0052] a. Cool down to 700°C at a cooling rate of 10°C per minute, and keep warm for 15 minutes at this temperature;

[0053] b. Cool down to 500°C at a cooling rate of 15°C per minute, and keep warm for 15 minutes at this tem...

Embodiment 3

[0065] A preparation method of a composite material composed of rags and resin, comprising the steps of:

[0066] (1) 2 parts by weight of carboxymethyl cellulose, 2 parts by weight of starch, 2 parts by weight of polyvinyl alcohol, 2 parts by weight of dextrin, 0.6 parts by weight of alumina, 0.3 parts by weight of silicon oxide, 0.4 parts by weight of magnesium oxide, 0.3 parts by weight of Parts by weight of chromium oxide are placed in 15 parts by weight of deionized water, and stirred evenly to obtain an impregnation solution;

[0067] (2) Arrange 7 parts by weight of crushed powder in the impregnating solution, stir at a speed of 50 r / min for 30 min; roast at a temperature of 900° C. for 2 h, and then cool down to room temperature to obtain granular materials;

[0068] The cooling process is:

[0069] a. Cool down to 700°C at a cooling rate of 10°C per minute, and keep warm for 15 minutes at this temperature;

[0070] b. Cool down to 500°C at a cooling rate of 15°C per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com