Textile production process

A manufacturing process and textile technology, applied in textiles and papermaking, dyeing, fiber treatment, etc., can solve problems such as hanging at the window, separation of polymer film and polyester or cotton screen, poor stickiness, etc. To achieve the effect of increasing temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

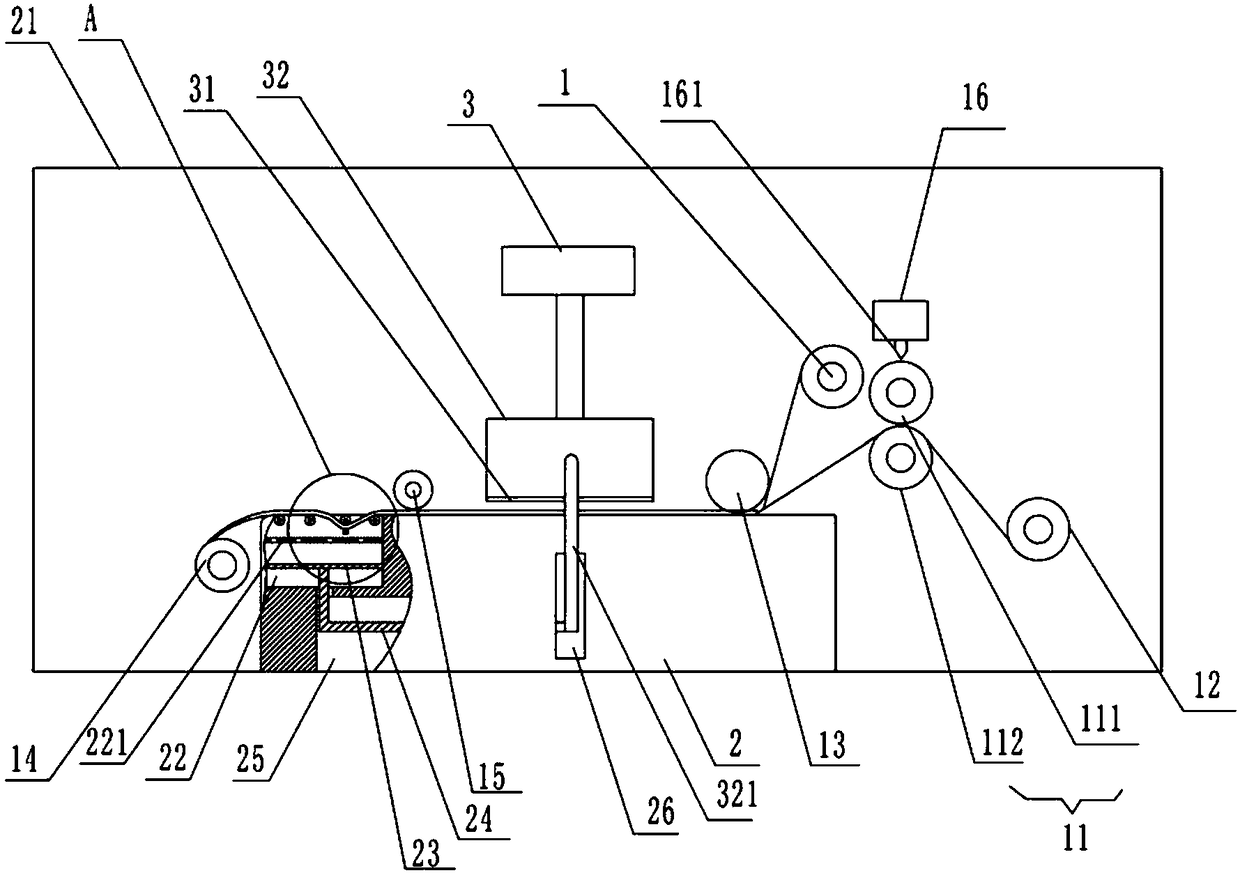

[0029] Such as figure 1 Shown, in order to achieve the above object, basic scheme of the present invention is as follows:

[0030] Textile production process, the steps are as follows:

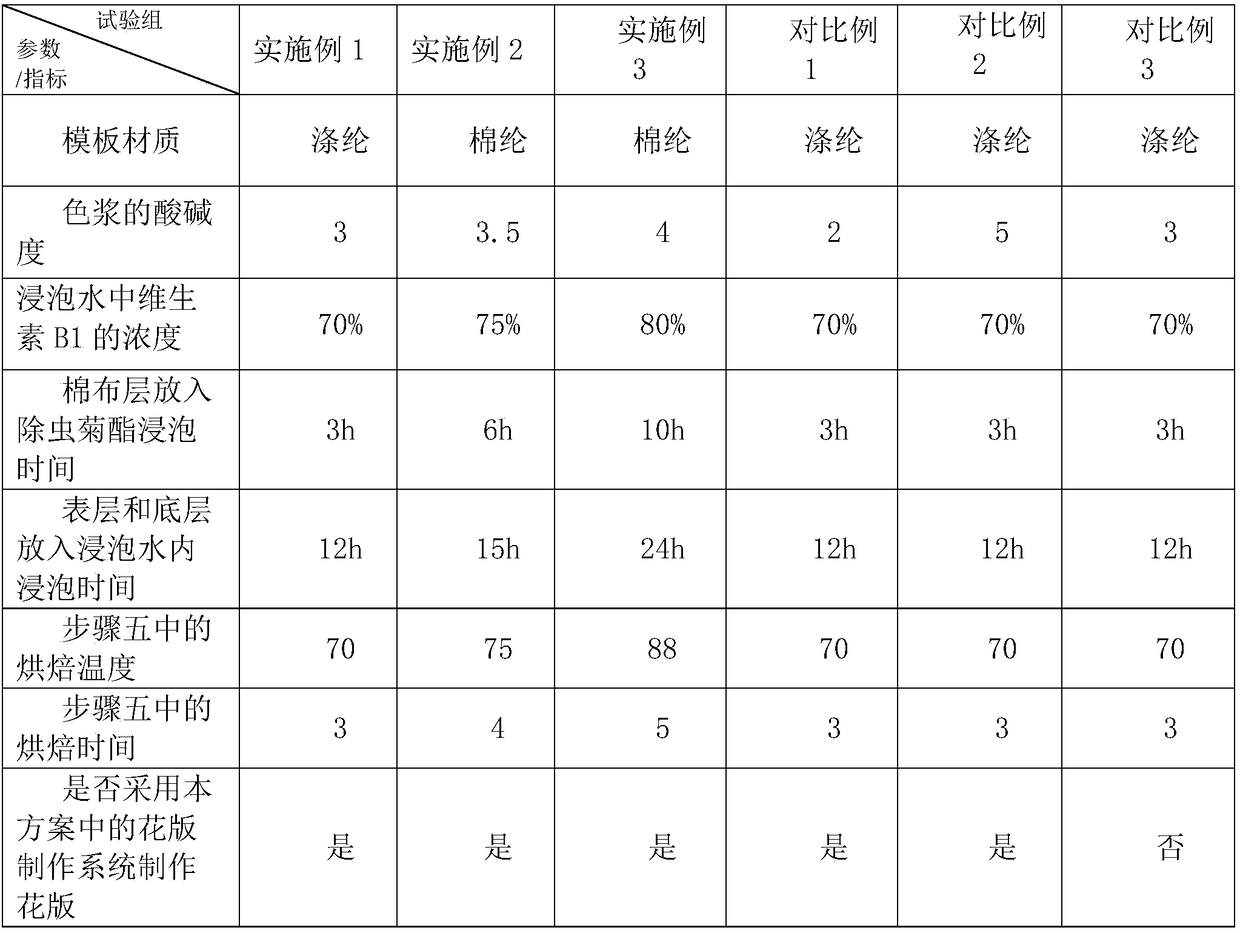

[0031] Step 1. Prepare color paste: prepare color paste: the color paste includes reactive dye paste; and the pH of the color paste is 3 to 4; there are many kinds of reactive dye paste. This scheme can take K-type reactive dye, and its dye molecules contain Monochloro-s-triazine active group.

[0032] Step 2. Prepare the fabric: prepare the fabric and vitamin B1, dissolve the vitamin B1 in softened water to form soaking water, and the concentration of vitamin B1 in the soaking water accounts for 70% to 80%. The fabric includes a surface layer, a middle layer and a bottom layer, the middle layer is an anti-mosquito layer, the anti-mosquito layer is a cotton cloth layer, and the cotton cloth layer is soaked in pyrethrin for 3 hours to 10 hours, and then air-dried to form; the surface layer an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com