Automobile electric tail door ECU control main board

A technology for controlling the main board and tailgate, applied in the power supply, electrical components, door/window accessories, etc., can solve the problems of overvoltage or overcurrent of peripheral equipment, high cost of replacing the mainboard, and difficulty in upgrading the mainboard. Filter function, improve the efficiency of fault repair, and facilitate the effect of upgrading and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

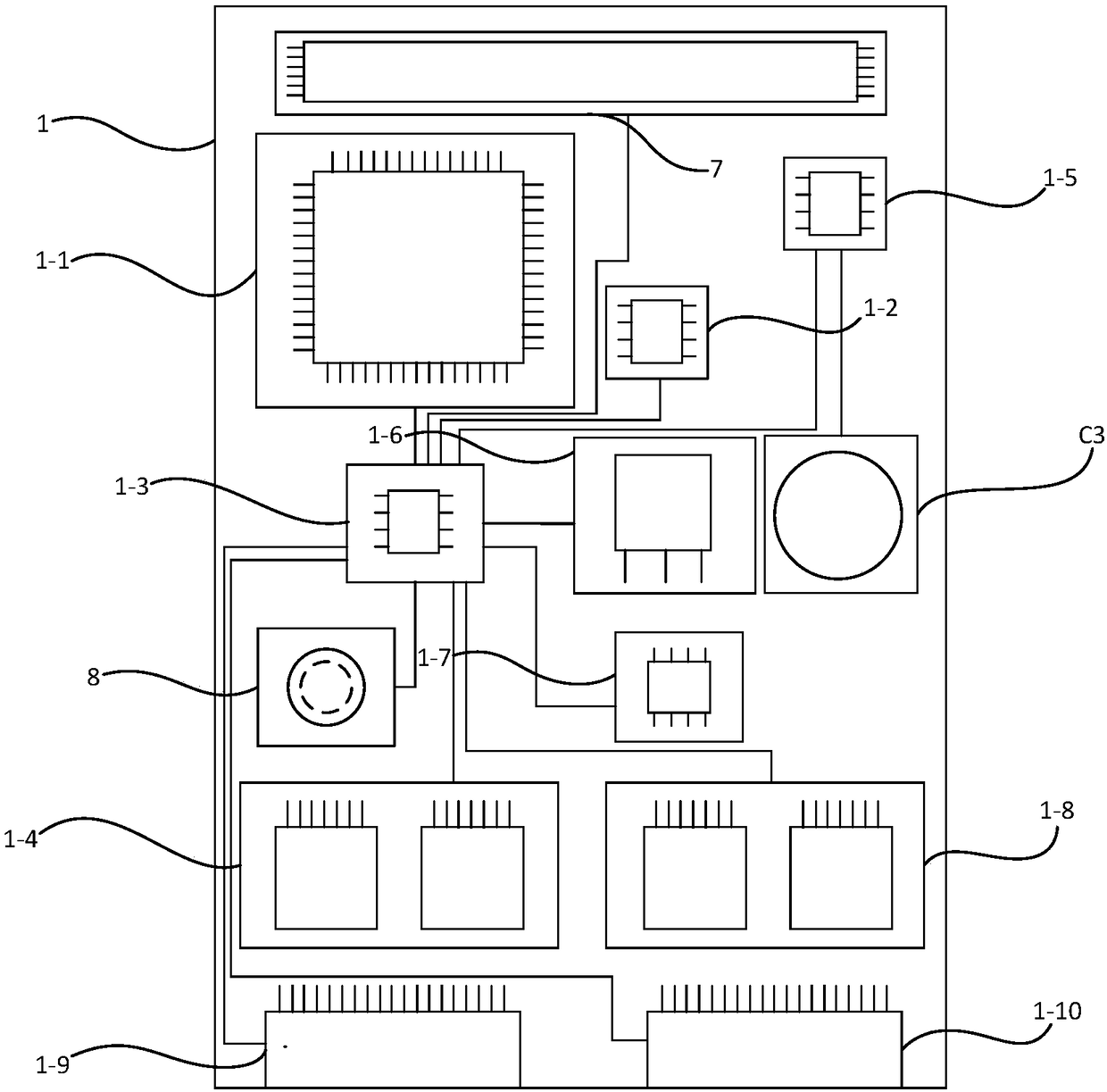

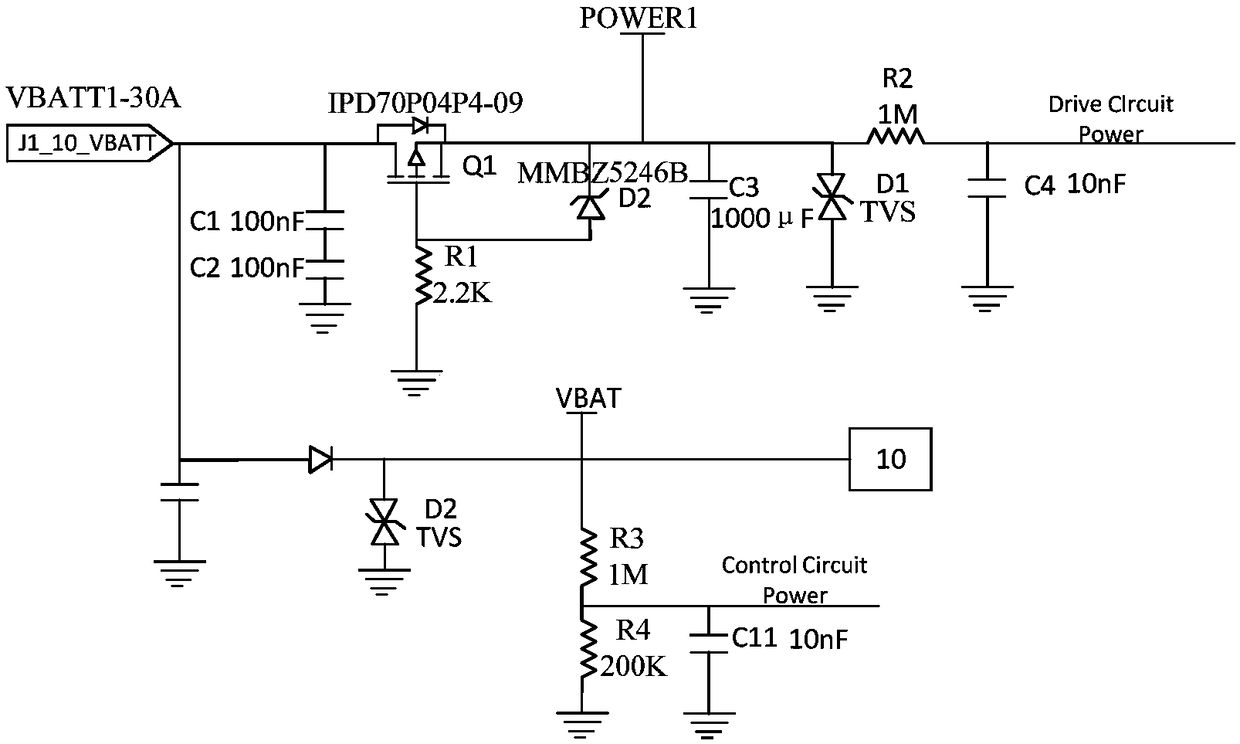

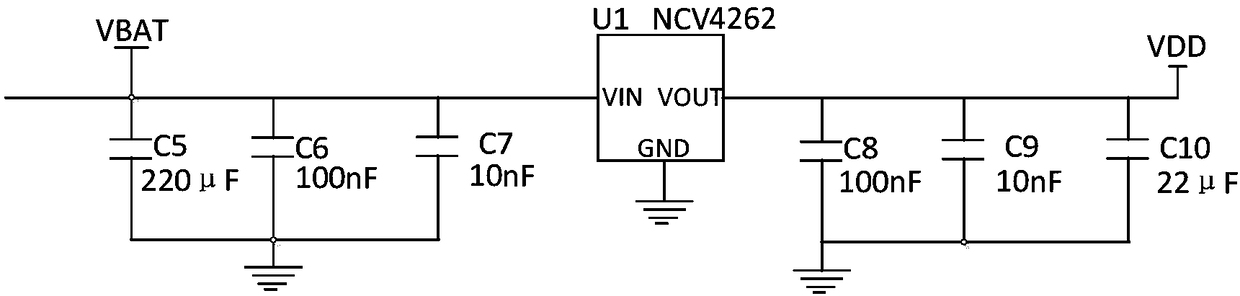

[0041] Embodiment: a kind of automobile electric tailgate ECU control main board, as Figure 1-Figure 4 As shown, it includes a main board 1, a microprocessor 1-1, an EEPROM circuit module 1-2, a high-speed CAN transceiver 1-3, a first bridge motor drive module 1-4 for driving an electric pole motor 2, and a power supply module 1-5. Power supply reverse connection protection circuit module 1-6. High-end voltage drive module 1-7 driving the tailgate unlocking motor 3. The second bridge motor drive module 1-8 driving the tailgate self-priming motor 4. The debugging and downloading interface 1-9 which is beneficial to the plugging of the emulator and the data status monitoring interface 1-10 which is beneficial to the plugging of the serial port conversion module;

[0042] The main board is provided with the microprocessor, the EEPROM circuit module, the high-speed CAN transceiver, the first bridge motor drive module for driving the electric strut motor, the internal chip power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com