Hydraulic pressure engine based on reversing valve

A reversing valve and engine technology, applied in the field of water energy power machinery, can solve the problems of low water energy utilization rate and large space occupation, and achieve the effects of simple structure, stable and reliable power output, and high energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

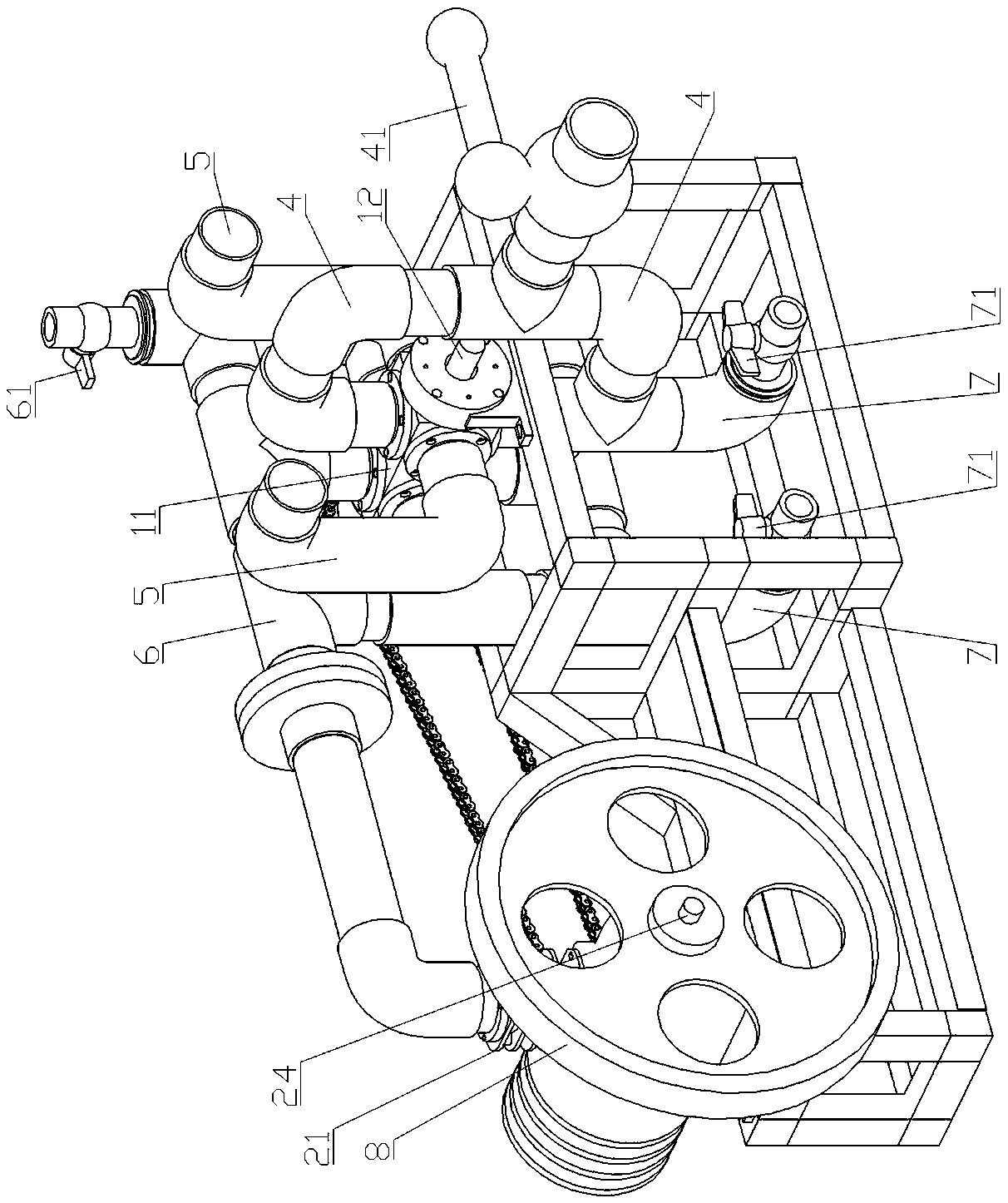

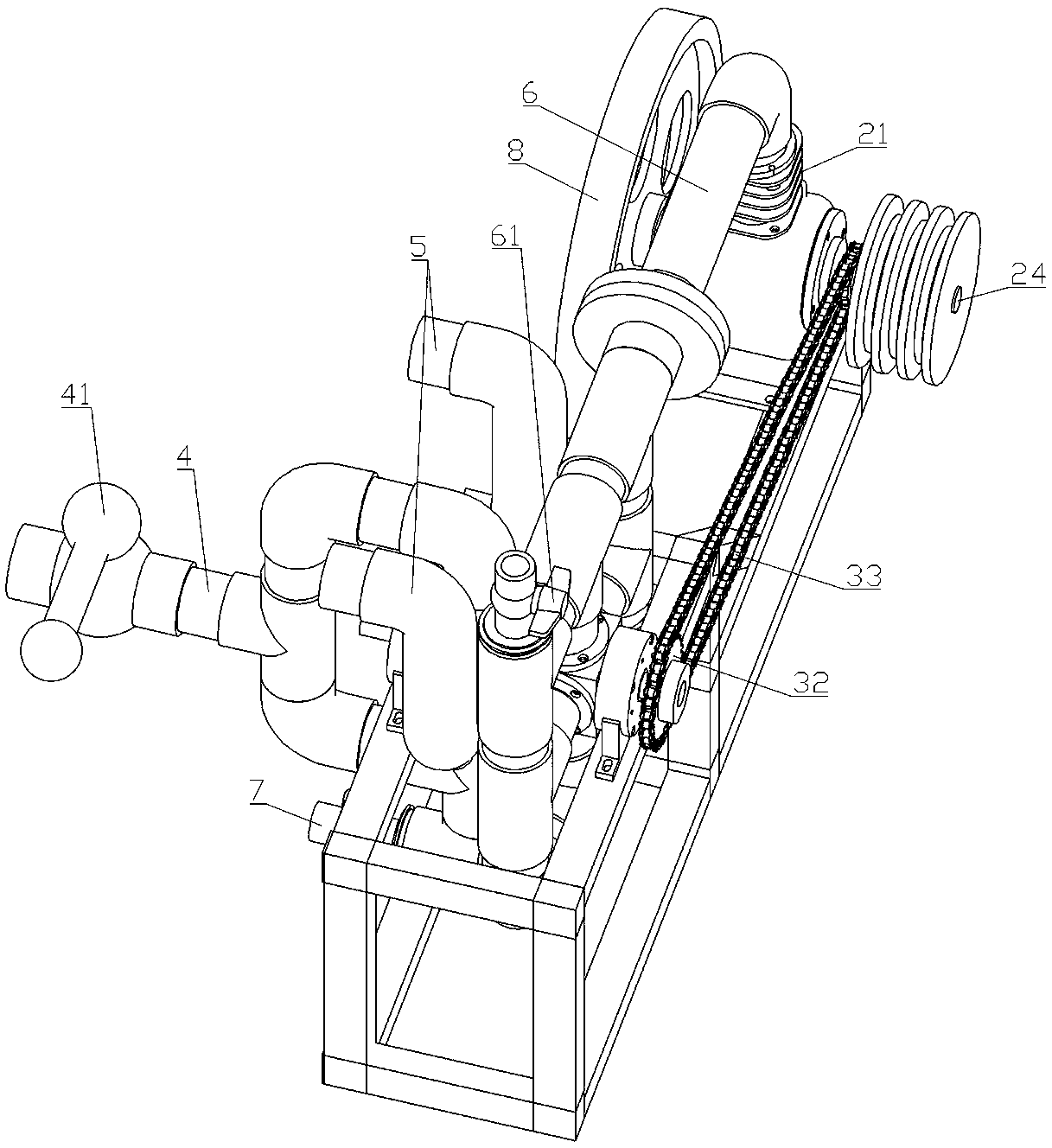

[0033] Such as figure 1 , 2 , 5, 6, 7, and 9, the hydraulic engine based on the reversing valve includes a reversing valve, an engine, a transmission assembly, a water inlet pipe 4, a drain pipe 5, a communication pipe 6 and a slag discharge pipe 7.

[0034] The reversing valve includes a casing 11 and a valve core 12 . The shell 11 is provided with a water inlet 111 , a water outlet A112 , a water outlet B113 and a water return port 114 . The valve core 12 is sealed and rotatably installed in the inner cavity of the casing 11, and its two ends protrude from the outside of the casing 11, and a water-permeable hole 121 is arranged on it, which realizes the opening or closing of the reversing valve through rotation. When the reversing valve is in the water inlet state, the permeable hole 121 of the spool 12 is rotated to communicate with the water inlet 111 and the water outlet A112 of the casing 11, and the inner cavity of the spool 12 is only connected with the water inlet 1...

Embodiment 2

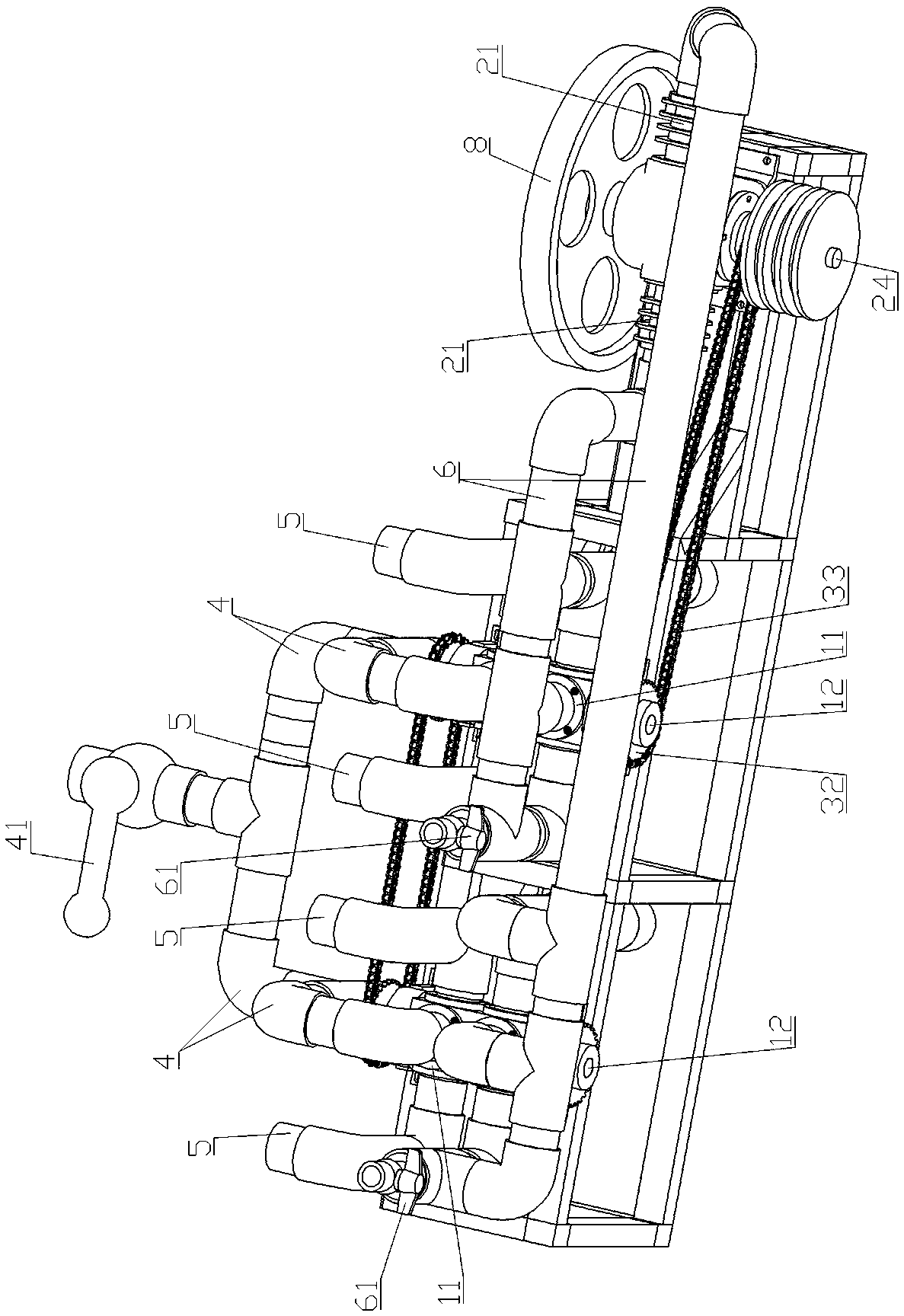

[0052] Such as image 3 , 4 , 5, 6, 8, and 10, compared with Embodiment 1, the present embodiment differs only in that the number of reversing valves is two, and the spools 12 of the two reversing valves are connected by a chain transmission pair, correspondingly Yes, there are two cylinder blocks 21, pistons 22, and connecting rods 23 of the engine. Compared with Embodiment 1, this embodiment has the advantage that the output of the crankshaft 24 is more stable.

[0053] Working principle of embodiment 2: the working principle of this embodiment is the same as that of embodiment 1, the only difference is that the working states of the two reversing valves are always opposite, that is, when one reversing valve is in the state of water intake, the other reversing valve The directional valve must be in the drain state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com