Device and method for testing condensate water formation

A test method and condensate technology, applied in the direction of measuring devices, material condensation, instruments, etc., can solve the problem of large temperature differences, wide ranges of atmospheric temperature and humidity changes, and inability to meet the requirements of material and mechanical product application verification and service reliability evaluation To achieve the effect of improving system reliability, mature technology, and reasonable data parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

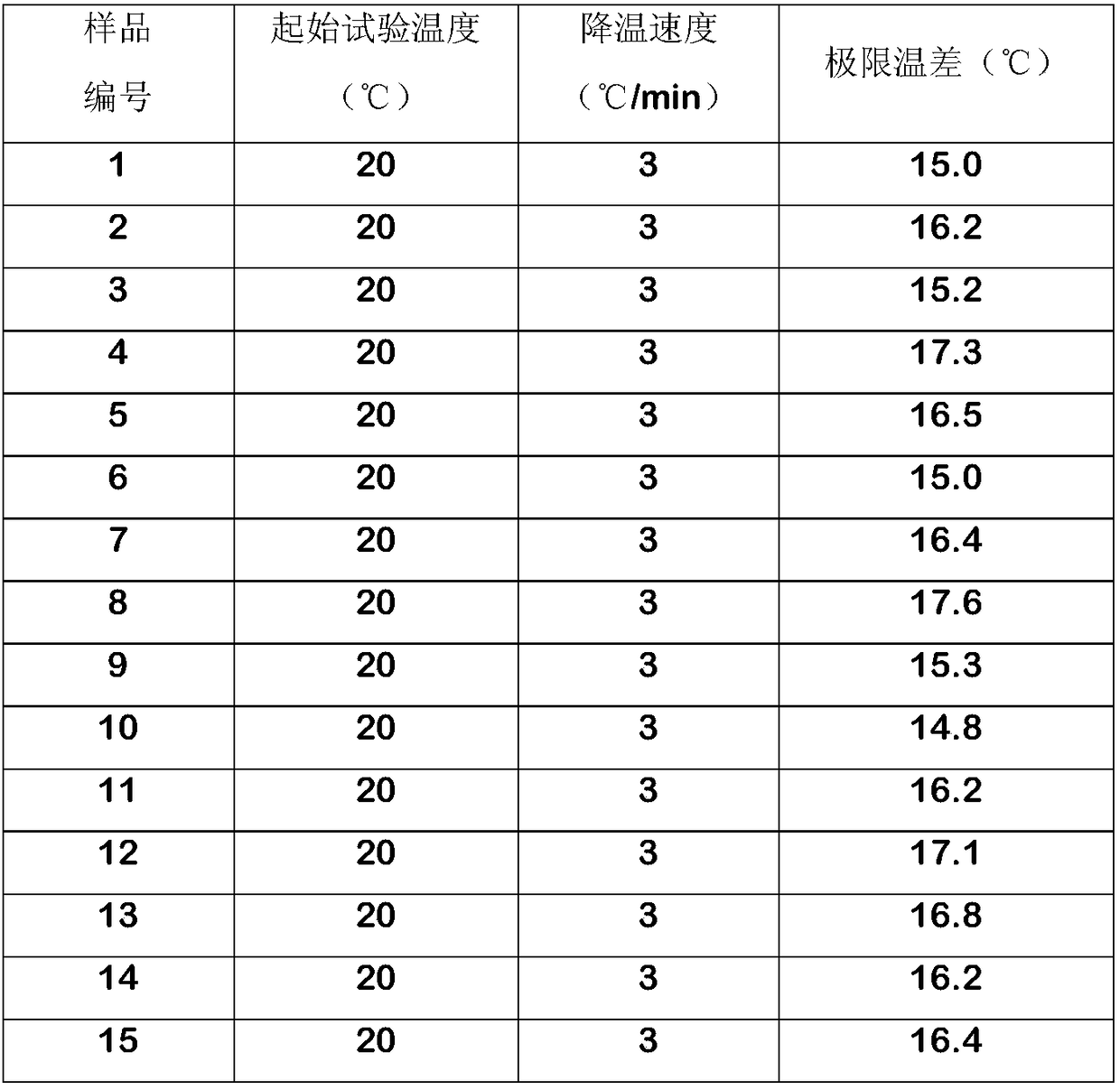

[0054] Embodiment 1 (measurement of limit temperature difference)

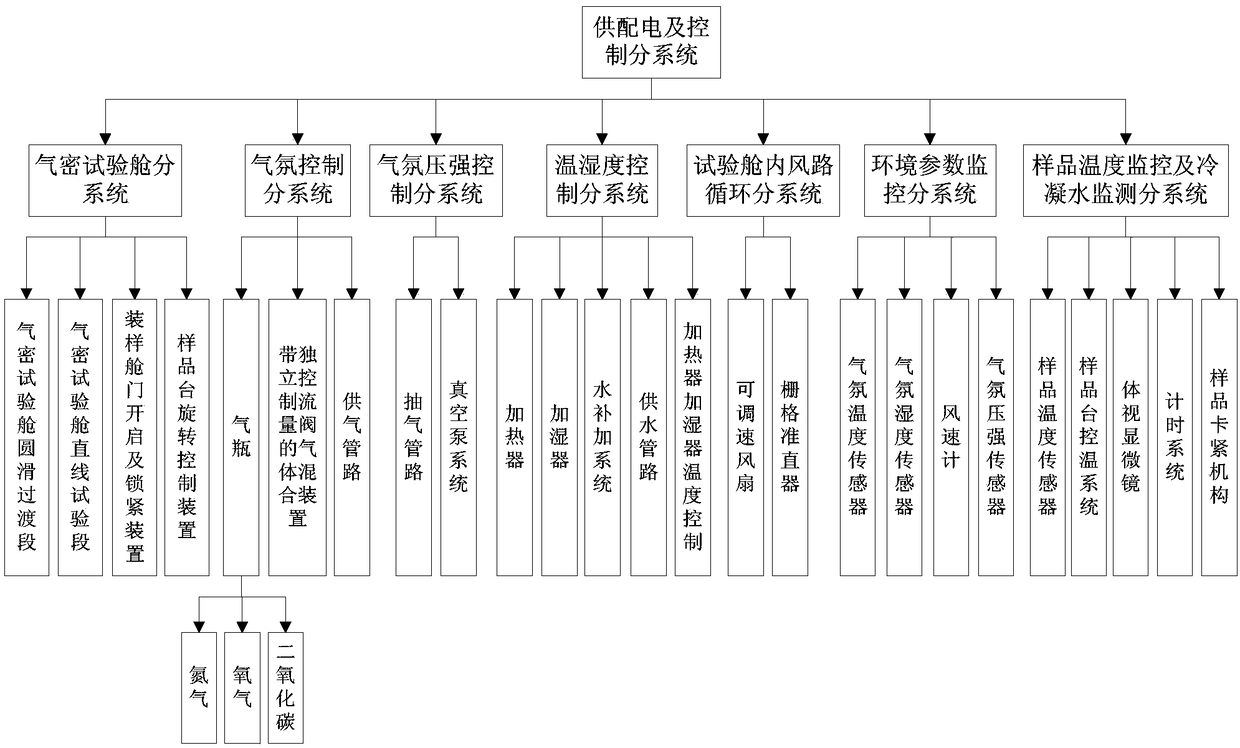

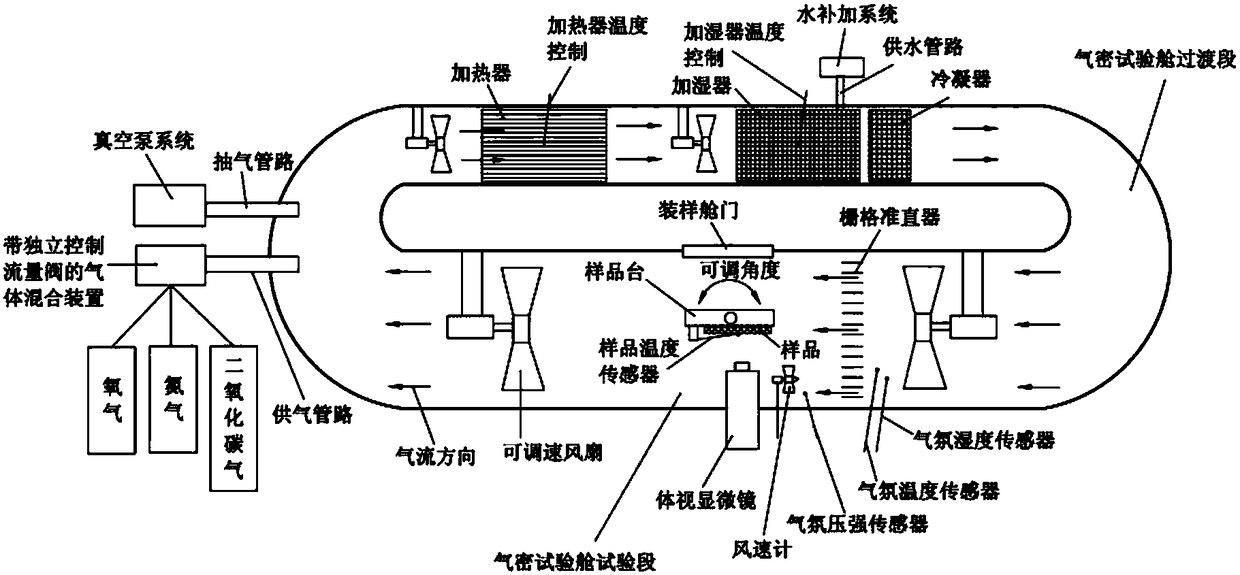

[0055] A test device for forming condensed water, the device includes an atmosphere control subsystem, an atmosphere pressure control subsystem, a temperature and humidity control subsystem, an airtight test cabin subsystem, an air circuit circulation subsystem in the test cabin, and an environmental parameter monitoring subsystem , Sample temperature monitoring and condensate monitoring subsystem, power supply and distribution and control subsystem;

[0056] The atmosphere control subsystem includes a gas mixing device with an independently controlled flow valve, an oxygen cylinder, a nitrogen cylinder, a carbon dioxide gas cylinder and a gas supply pipeline, and the gas mixing device with an independently controlled flow valve includes a pressure reducing valve, a flow meter And four-way (three in and one out), oxygen cylinders, nitrogen cylinders, and carbon dioxide cylinders are equipped with a pressure re...

Embodiment 2

[0104] Embodiment 2 (product verification test)

[0105] (1) Pretreatment of the sample to be tested, that is, the circuit board sample with an outer contour size of 40mm×50mm×10mm (thickness) is blown off the dust attached to the surface with an ear cleaning ball, and then placed in a desiccator for standby.

[0106] (2) The laboratory environment is 22° C., 45% RH, and 0.9 atm as measured by a thermo-hygrometer.

[0107] (3) Initialize the test device, set the initial environmental conditions (temperature, humidity, pressure) parameters through the power supply and distribution and control subsystems: atmosphere 22°C, 30% RH, 0.9atm, sample stage 32°C, and run the system using The heater, humidifier, and condenser of the temperature and humidity control system and the temperature control system of the sample stage rotation control device are started. Adjust the gas cylinder pressure reducing valve and flow valve of the atmosphere control subsystem to obtain 0.9 atm gas with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com