Petrochemical plant inspection robot environment modeling and map building device and method

An inspection robot and map construction technology, which is used in measurement devices, instruments, surveying and navigation, etc., can solve problems such as being unable to cope with a large number of indoor and sheltered environments, high equipment cost, and unfavorable for real-time map update, and achieves a high level of improvement. Adaptability and accuracy, guaranteeing safety and reliability, overcoming the effect of quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

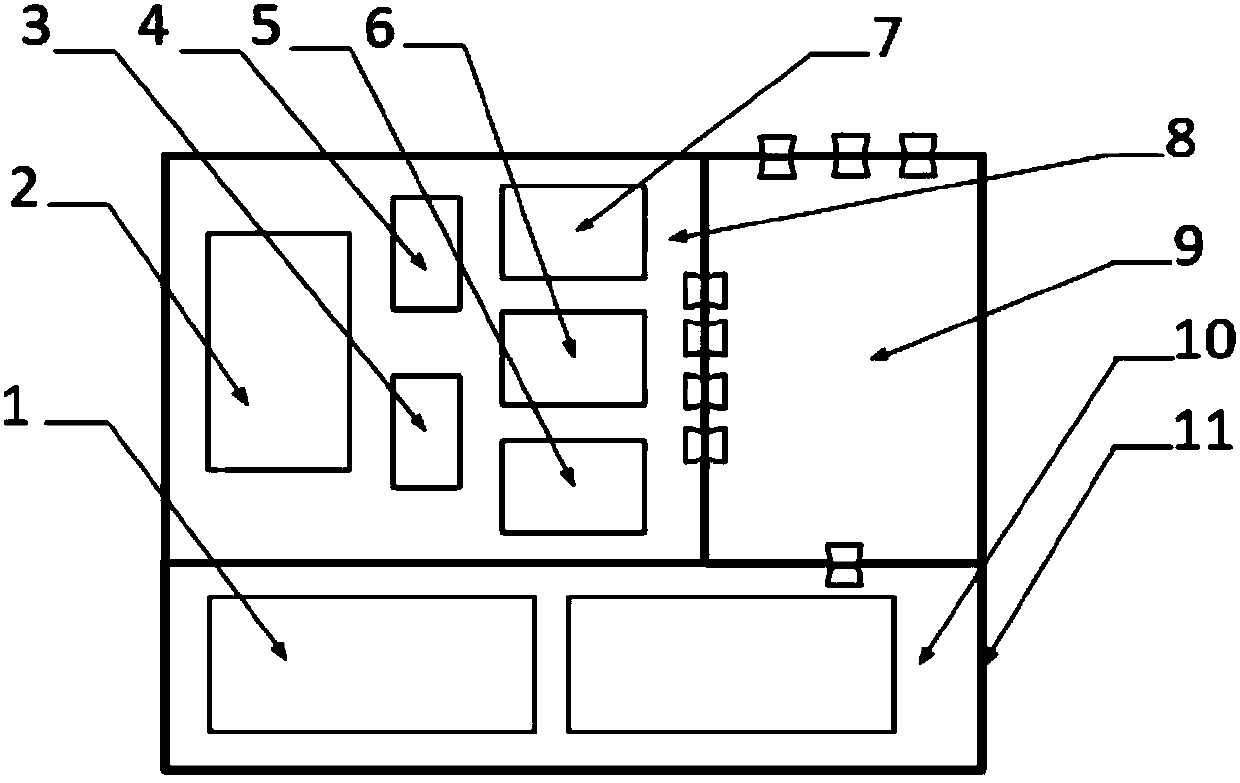

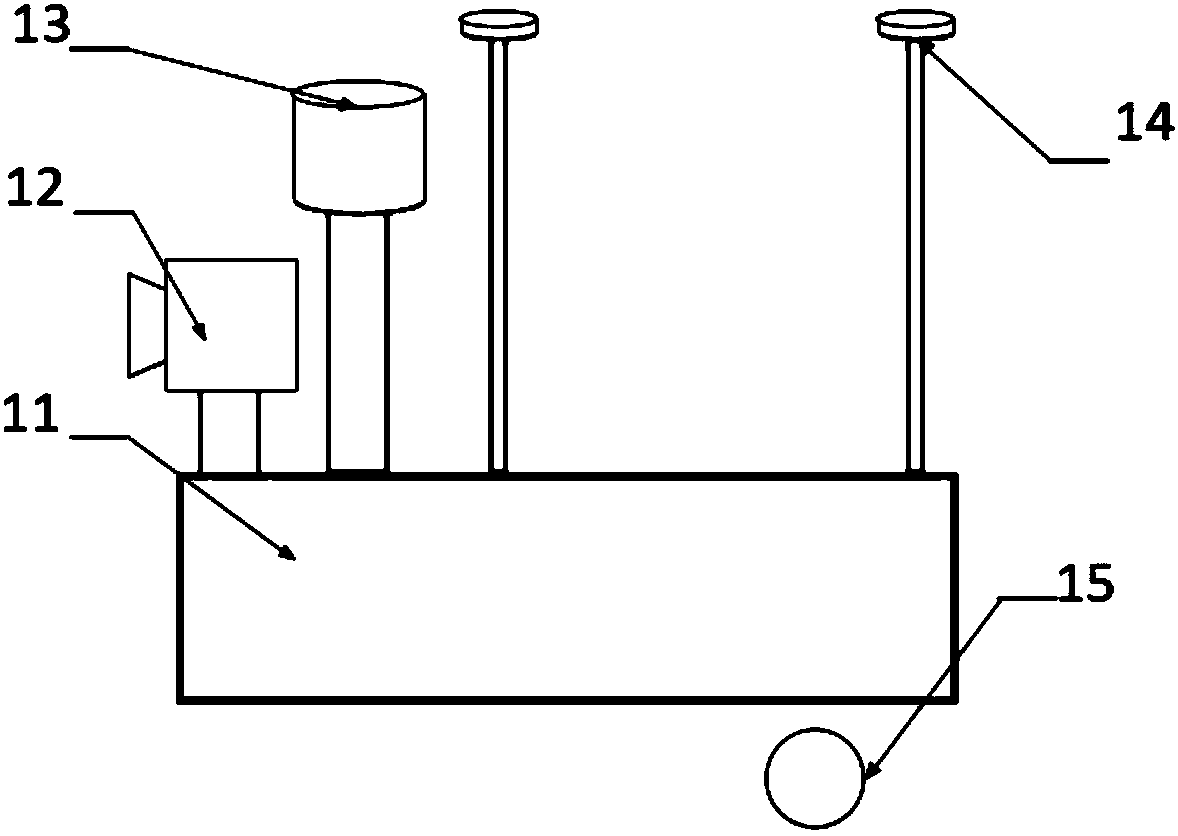

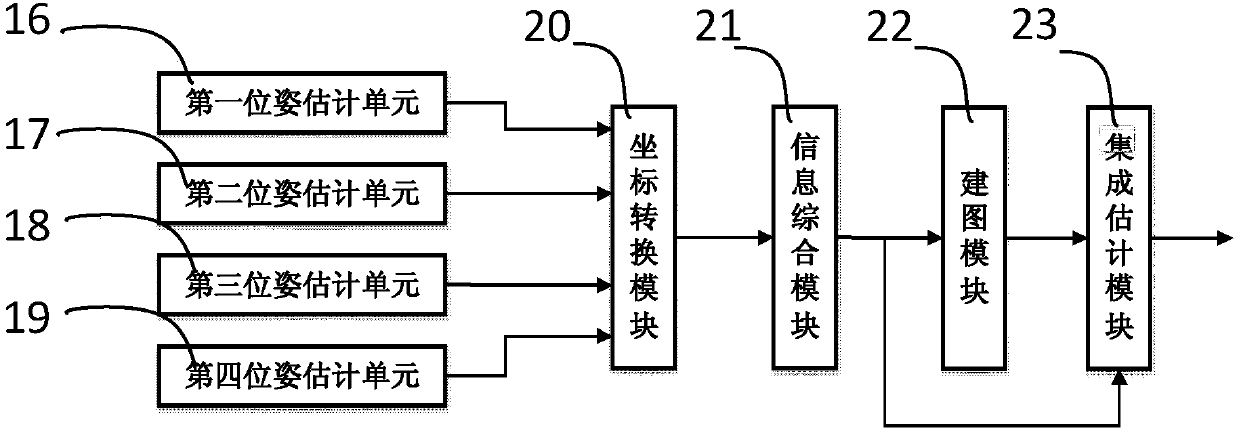

[0058] A petrochemical factory inspection robot environment modeling and map construction device, such as figure 1 As shown, it includes power module 1, industrial computer 2, inertial measurement module 3, differential GPS module 4, power conversion module 5, signal isolation safety barrier module 6, communication module 7 and flameproof housing 11, and flameproof housing 11 points There are three chambers: main control chamber 8, wiring chamber 9 and power supply chamber 10, industrial computer 2, inertial measurement module 3, differential GPS module 4, power conversion module 5, signal isolation safety barrier module 6 and communication module 7 are installed in The main control chamber 8 and the wiring chamber 9 are connected to various power supply and communication cables, and the power supply chamber 10 is equipped with a power modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com