Underwater HDPE umbilical cable cabin-passing sealing process

A technology of umbilical cable and cabin penetration, which is applied in the field of underwater HDPE umbilical cable penetration sealing technology, which can solve the problems of inefficiency, internal cable and optical fiber cable composite structure damage, etc., and achieve the effect of convenient installation, reliable and effective process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

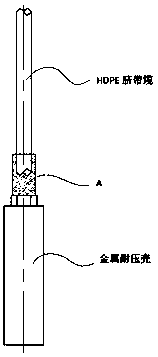

[0038] Embodiment 1, the present invention takes the connection between the metal pressure vessel and the outer sheath of the HDPE umbilical cable as an example to illustrate the HDPE umbilical cable penetration sealing process. The metal pressure vessel used in this embodiment is one end closed and the other end open metal container.

[0039] like figure 1 As shown, a kind of underwater HDPE umbilical cable penetrating sealing process includes the following steps:

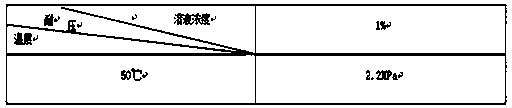

[0040] 1. Impregnation step: completely immerse the outer sheath of HDPE umbilical cable in 1% weak acid solution, place it in an oven at 50°C, keep it warm for 0.2-2 hours, and then take it out.

[0041] The weakly acidic solution described in the above steps includes at least one selected from the following groups: ammonium phosphate, ammonium hydrogen phosphate, ammonium dihydrogen phosphate, ammonium sulfate, ammonium persulfate, ammonium peroxodisulfate, ammonium bisulfate, ammonium nitrate, nitric acid Amm...

Embodiment 2

[0049] Embodiment 2, the present invention takes the connection between the metal pressure vessel and the outer sheath of the HDPE umbilical cable as an example to illustrate the HDPE umbilical cable penetration sealing process. The metal pressure vessel used in this embodiment is one end closed and the other end open metal container.

[0050] like figure 1 As shown, a kind of underwater HDPE umbilical cable penetrating sealing process includes the following steps:

[0051] 1. Impregnation step: completely immerse the outer sheath of HDPE umbilical cable in 15% weak acid solution, place it in an oven at 60°C, keep it warm for 0.2-2 hours, and then take it out.

[0052] The weakly acidic solution described in the above steps includes at least one selected from the following groups: ammonium phosphate, ammonium hydrogen phosphate, ammonium dihydrogen phosphate, ammonium sulfate, ammonium persulfate, ammonium peroxodisulfate, ammonium bisulfate, ammonium nitrate, nitric acid Am...

Embodiment 3

[0060] Embodiment 3, the present invention takes the connection between the metal pressure vessel and the outer sheath of the HDPE umbilical cable as an example to illustrate the HDPE umbilical cable penetrating sealing process. The metal pressure vessel used in this embodiment is one end closed and the other end open metal container.

[0061] like figure 1 As shown, a kind of underwater HDPE umbilical cable penetrating sealing process includes the following steps:

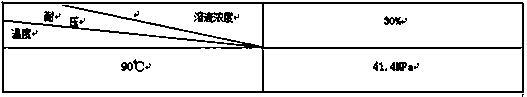

[0062] 1. Impregnation step: completely immerse the outer sheath of HDPE umbilical cable in 30% weak acid solution, place it in an oven at 90°C, keep it warm for 0.2-2 hours, and then take it out.

[0063] The weakly acidic solution described in the above steps includes at least one selected from the following groups: ammonium phosphate, ammonium hydrogen phosphate, ammonium dihydrogen phosphate, ammonium sulfate, ammonium persulfate, ammonium peroxodisulfate, ammonium bisulfate, ammonium nitrate, nitric acid Am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com