Extraction technology of fig dietary fiber bars

A dietary fiber and extraction process technology, which is applied in the field of extraction process of fig dietary fiber sticks, can solve problems such as complicated processes, and achieve the effects of simple preparation process, good taste, and fewer production personnel and equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

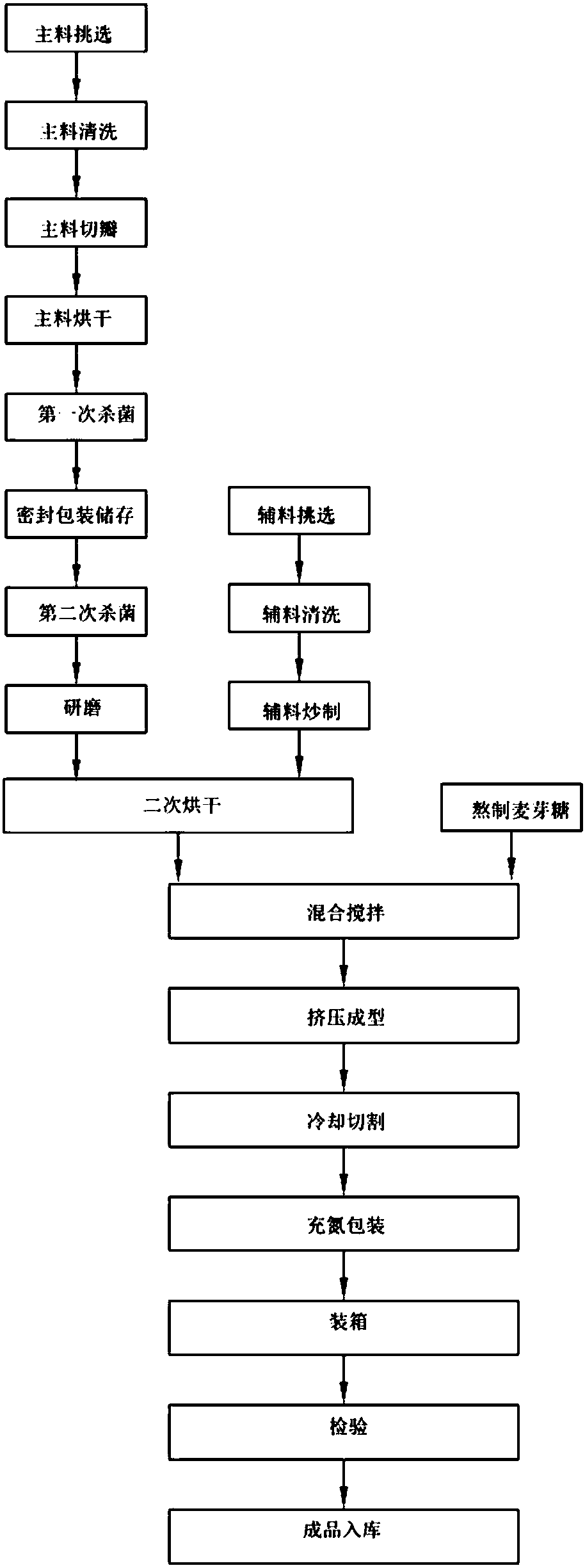

[0040] A kind of extraction process of fig dietary fiber bar, such as figure 1 As shown, the fig dietary fiber bar includes main ingredients and auxiliary materials, the main ingredients are figs, and the auxiliary materials are almonds, peanuts, sesame, following steps:

[0041] S1: Raw material processing: select high-quality main materials and auxiliary materials, and put the high-quality main materials and auxiliary materials into the continuous automatic cleaning machine for cleaning, obtain clean main materials and auxiliary materials, and cut the high-quality and clean main materials into pieces for use;

[0042] S2: Drying of the main ingredients: evenly place the cut main ingredients on the baking tray and put them into the oven for baking. The baking temperature in the oven is 65°C, and the baking time is 8 hours. The moisture in the final main ingredient is 10%;

[0043] S3: main ingredient sterilization: sterilize the baked main ingredient;

[0044] S30: Cooling ...

Embodiment 2

[0053] A kind of extraction process of fig dietary fiber bar, such as figure 1 As shown, the fig dietary fiber bar includes main ingredients and auxiliary materials, the main ingredients are figs, and the auxiliary materials are almonds, peanuts, sesame, following steps:

[0054] S1: Raw material processing: select high-quality main materials and auxiliary materials, and put the high-quality main materials and auxiliary materials into the continuous automatic cleaning machine for cleaning, obtain clean main materials and auxiliary materials, and cut the high-quality and clean main materials into pieces for use;

[0055] S2: Drying of the main ingredients: evenly place the cut main ingredients on the baking tray and put them into the oven for baking. The baking temperature in the oven is 69°C, and the baking time is 9 hours. The moisture in the final main ingredient is 12%;

[0056] S3: main ingredient sterilization: sterilize the baked main ingredient;

[0057] S30: Cooling ...

Embodiment 3

[0066] A kind of extraction process of fig dietary fiber bar, such as figure 1 As shown, the fig dietary fiber bar includes main ingredients and auxiliary materials, the main ingredients are figs, and the auxiliary materials are almonds, peanuts, sesame, following steps:

[0067] S1: Raw material processing: select high-quality main materials and auxiliary materials, and put the high-quality main materials and auxiliary materials into the continuous automatic cleaning machine for cleaning, obtain clean main materials and auxiliary materials, and cut the high-quality and clean main materials into pieces for use;

[0068] S2: Drying of the main ingredients: evenly place the cut main ingredients on the baking tray and put them into the oven for baking. The baking temperature in the oven is 72°C, and the baking time is 10 hours. The moisture in the final main ingredient is 13%;

[0069] S3: main ingredient sterilization: sterilize the baked main ingredient;

[0070] S30: Cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com