Preparation method of novel liquid-state nano complex flocculant

A flocculant, liquid technology, applied in the field of preparation of new liquid nano-complex flocculants, to achieve the effect of improved treatment efficiency, sufficient reaction, and good sewage treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

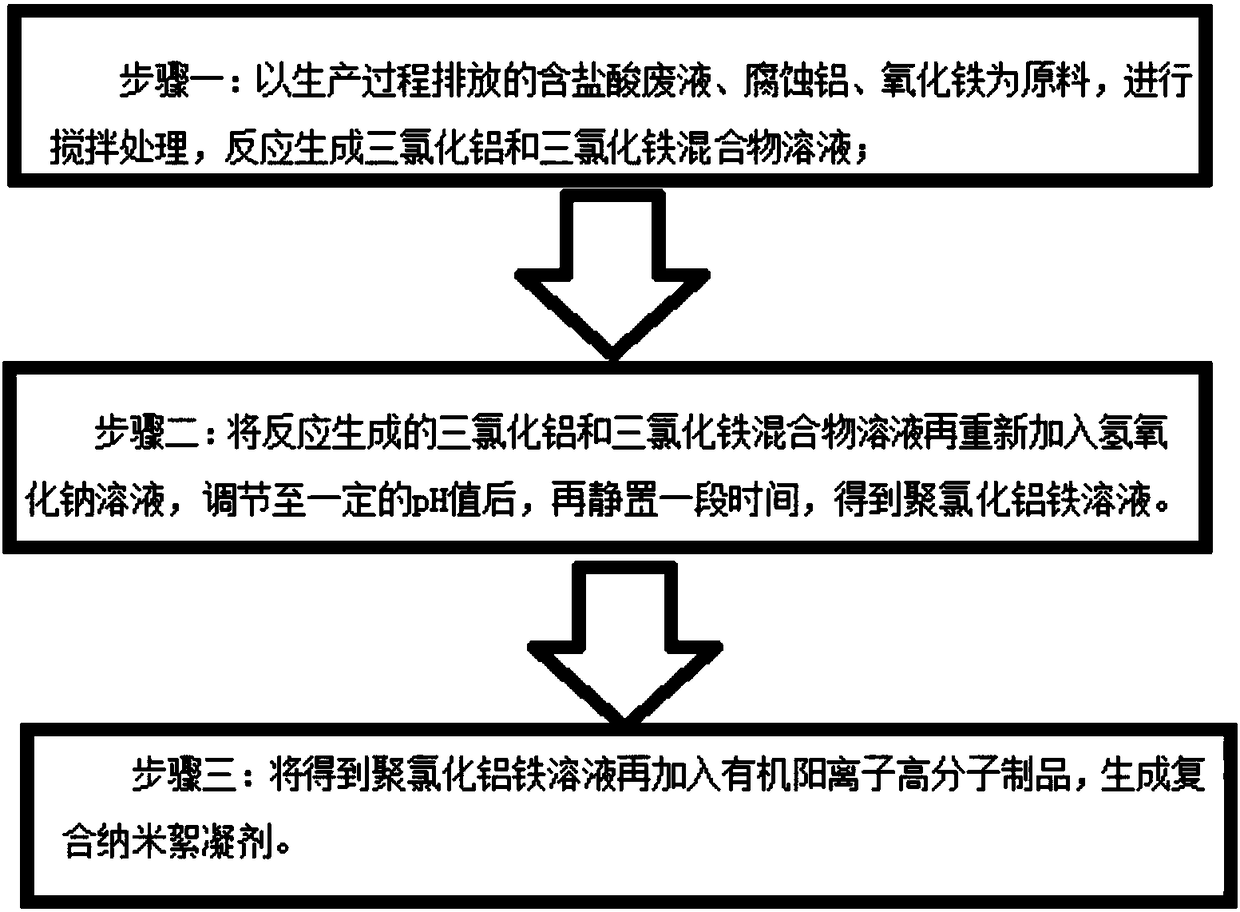

[0031] A method for preparing a novel liquid nano-complex flocculant, comprising the following steps:

[0032] Step 1: using waste liquid containing hydrochloric acid, corroded aluminum, and oxidized iron discharged from the production process as raw materials, performing stirring treatment, and reacting to form a mixture solution of aluminum trichloride and ferric chloride;

[0033] Step 2: re-add sodium hydroxide solution to the mixture solution of aluminum trichloride and ferric chloride generated by the reaction, adjust to a certain pH value, and then let it stand for a period of time to obtain a polyaluminum ferric chloride solution.

[0034] The method also includes step three: adding the obtained polyaluminum ferric chloride solution into organic cationic macromolecular products to form a composite nano flocculant.

[0035] The specific step of step 1 is to gradually add corroded aluminum and oxidized iron to the waste liquid containing hydrochloric acid at 65°C to 75°C...

Embodiment 1

[0044] A method for preparing a novel liquid nano-complex flocculant, comprising the following steps:

[0045] Step 1: using waste liquid containing hydrochloric acid, corroded aluminum, and oxidized iron discharged from the production process as raw materials, performing stirring treatment, and reacting to form a mixture solution of aluminum trichloride and ferric chloride;

[0046] Step 2: re-add the sodium hydroxide solution to the mixture solution of aluminum trichloride and ferric chloride generated by the reaction, adjust to a certain pH value, and then let it stand for a while to obtain a polyaluminum ferric chloride solution to form a composite Nano flocculants.

Embodiment 2

[0048] A method for preparing a novel liquid nano-complex flocculant, comprising the following steps:

[0049] Step 1: using waste liquid containing hydrochloric acid, corroded aluminum, and oxidized iron discharged from the production process as raw materials, performing stirring treatment, and reacting to form a mixture solution of aluminum trichloride and ferric chloride;

[0050] Step 2: re-add sodium hydroxide solution to the mixture solution of aluminum trichloride and ferric chloride generated by the reaction, adjust to a certain pH value, and then let it stand for a period of time to obtain a polyaluminum ferric chloride solution.

[0051] Step 3: adding the obtained polyaluminum ferric chloride solution to organic cationic polymer products to form a composite nano flocculant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com