Solidified soil and anti-fouling and anti-seepage treatment method for large coal yards

A treatment method and soil solidification technology, which can be applied in protection devices, buildings, infrastructure engineering, etc., can solve the problems of high concrete floor price and difficult replacement of geomembrane, and achieve the reduction of comprehensive unit price, meet the requirements of stacking weight, and meet the The effect of impermeability requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The dry clay of 85 parts by weight is spread in the mould, and the clay thickness is 23 centimetres. Pour 9.2 parts by weight of a 2.17% soil stabilizer solution (9 parts by weight of water and 0.2 parts by weight of soil stabilizer), and stir evenly. Pour 15 parts by weight of cement into the mold and stir evenly. After leveling, follow the principle of "light first and then heavy, first slow and then fast, first both sides and then the middle, first static pressure and then vibration" to carry out rolling until the compaction coefficient is 0.95 and stop. Lay two more layers of solidified soil on the compacted solidified soil in the same way as before. Adopting the method of covering the plastic film to maintain the health, the temperature is 30 ℃, and the curing is maintained for one week in a humid environment to obtain the curing agent anti-seepage layer, and its thickness is 60 cm.

Embodiment 2-6

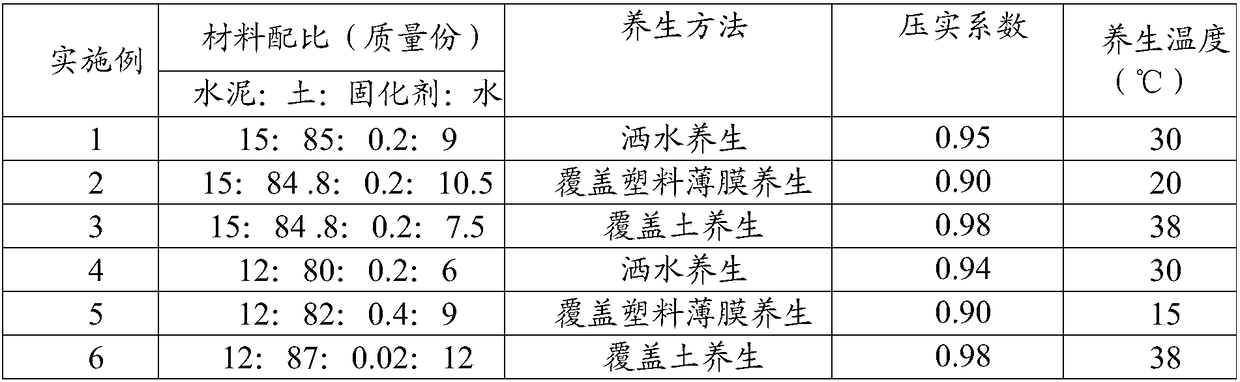

[0059] Embodiment 2-6 carries out according to the same step as embodiment 1, and the technical parameter of each embodiment is as shown in table 1:

[0060] The technical parameter summary of each embodiment of table 1

[0061]

[0062] Performance Testing

[0063] The curing agent anti-seepage layer obtained in Examples 1-10 is subjected to a strength test, and the evaluation results are shown in Table 2:

[0064] Table 2 Summary of strength test results

[0065]

[0066] Coal yard floor project of a raw material yard in Rizhao, Shandong

[0067] According to the EIA report of this project, the raw material site (coal yard) belongs to the general pollution prevention and control area: the anti-seepage performance should be comparable to that of a 1.5-meter-thick clay layer (permeability coefficient 1.0×10 -7 cm / s) equivalent. Using solidified soil as the surface layer plan:

[0068] 1. Construction method selection:

[0069] The total thickness of the solidified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com