Hyper-concentrated dish washing liquid and preparation method thereof

A dishwashing liquid and ultra-concentrated technology, which is applied in the field of detergent, can solve the problems that the internal components of detergent are easily affected by the environment, high energy consumption in transportation and production, easy to be destroyed or volatilized, and achieve low cost and convenient transportation , high biodegradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

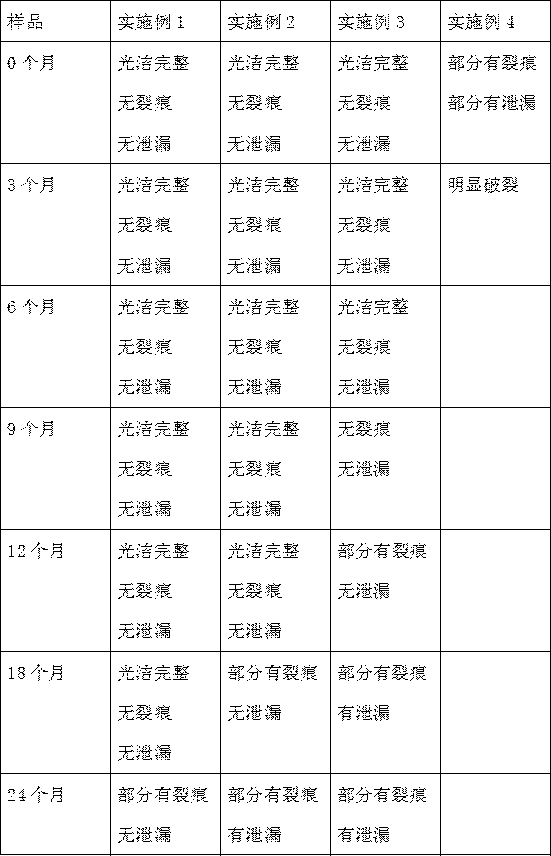

Examples

Embodiment 1

[0050] Ultra-concentrated dishwashing liquid, containing the following raw materials in parts by weight: 8 parts of deionized water; 0.1 part of disodium EDTA; 20 parts of sodium laureth sulfate; 20 parts of alkyl glycosides; 20 parts of benzenesulfonic acid; 3 parts of triethanolamine; 0.5 parts of essence; 30 parts of high-quality isomeric C13 alkanol polyoxyethylene ether; 10 parts of lauramide propyl ammonium oxide; 0.2 parts of citric acid; 0.1 part of preservative. The preservative is a mixture of methylchloroisothiazolinone and methylisothiazolinone, magnesium chloride and magnesium nitrate.

[0051] The preparation method of super-concentrated dishwashing liquid comprises the following steps:

[0052] 1) Weigh deionized water and disodium EDTA into a stirring pot, stirring at a speed of 20r / min; stir until a transparent liquid.

[0053] 2) Weigh sodium lauryl ether sulfate, alkyl glucoside, glycerin, and propylene glycol respectively and add them into a stirring pot a...

Embodiment 2

[0060] Ultra-concentrated dishwashing liquid, containing the following raw materials in parts by weight: 6 parts of deionized water; 0.05 parts of disodium EDTA; 15 parts of sodium laureth sulfate; 25 parts of alkyl glycosides; 15 parts of benzenesulfonic acid; 5 parts of triethanolamine; 0.3 parts of essence; 35 parts of high-quality isomeric C13 alkanol polyoxyethylene ether; 15 parts of lauramide propyl ammonium oxide; 0.5 parts of citric acid; 0.2 parts of preservatives. The preservative is a mixture of methylchloroisothiazolinone and methylisothiazolinone, magnesium chloride and magnesium nitrate.

[0061] The preparation method of super-concentrated dishwashing liquid comprises the following steps:

[0062] 1) Weigh deionized water and disodium EDTA into a stirring pot, stirring at a speed of 20r / min; stir until a transparent liquid.

[0063] 2) Weigh sodium lauryl ether sulfate, alkyl glucoside, glycerin, and propylene glycol respectively and add them into a stirring p...

Embodiment 3

[0070] Ultra-concentrated dishwashing liquid, containing the following raw materials by weight: 11 parts of deionized water; 0.15 parts of disodium EDTA; 25 parts of sodium laureth sulfate; 15 parts of alkyl glycosides; 10 parts of glycerin; 20 parts of benzenesulfonic acid; 4 parts of triethanolamine; 0.4 parts of essence; 25 parts of high-quality isomeric C13 alkanol polyoxyethylene ether; 10 parts of lauramide propyl ammonium oxide; 0.3 parts of citric acid; 0.1 part of preservative. The preservative is a mixture of methylchloroisothiazolinone and methylisothiazolinone, magnesium chloride and magnesium nitrate.

[0071] The preparation method of super-concentrated dishwashing liquid comprises the following steps:

[0072] 1) Weigh deionized water and disodium EDTA into a stirring pot, stirring at a speed of 20r / min; stir until a transparent liquid.

[0073] 2) Weigh sodium lauryl ether sulfate, alkyl glucoside, glycerin, and propylene glycol respectively and add them into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com