Solid rocket erecting system and erecting method

A solid rocket and rocket launch technology, applied in the field of hydraulic systems, can solve problems such as complex systems, high oil cleanliness and electrical control requirements, increased control and implementation difficulties, etc., to achieve easy control, simple structure, and erection speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] First of all, it needs to be explained that the orientation words such as up, down, front, back, left, and right in the present invention are only described according to the accompanying drawings, so as to facilitate understanding, and are not intended to limit the technical solution and scope of protection of the present invention. .

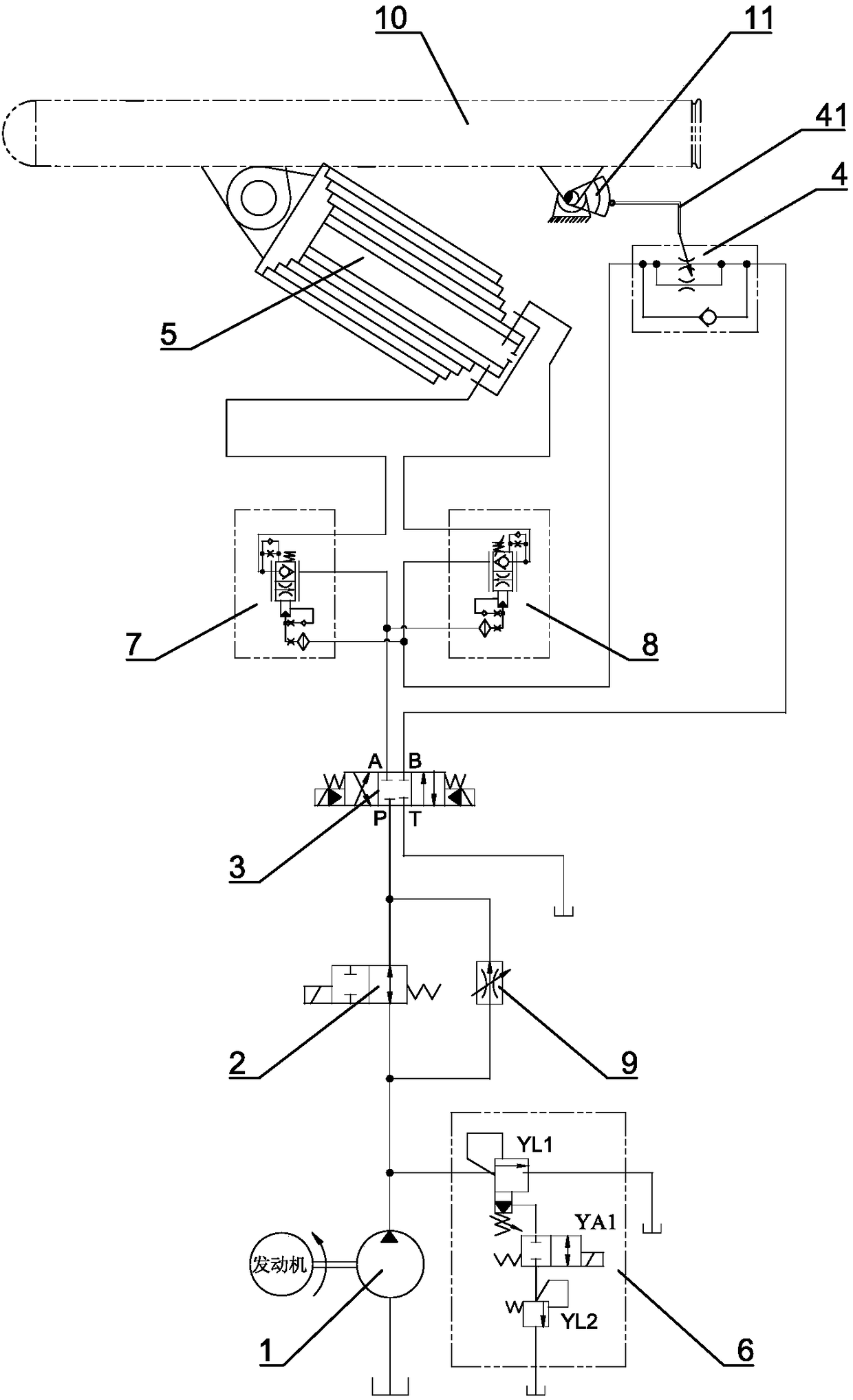

[0018] Such as figure 1 Shown is a specific embodiment of a solid rocket erecting system of the present invention, including a quantitative pump 1 , a shut-off valve 2 , a reversing valve 3 , a machine-hydraulic throttle valve 4 and an erecting hydraulic cylinder 5 . The machine fluid throttle valve 4 is provided with a bypass throttle port and a sensing rod 41 . The quantitative pump 1 is connected to the cut-off valve 2 and the oil inlet P of the reversing valve 3 in turn through the first pipeline, and the working oil port A of the reversing valve 3 is connected to the positive chamber of the vertical hydraulic cylinder 5 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com