Capacitor producing device and capacitor manufacturing method

A technology for production equipment and capacitors, which is applied in capacitor manufacturing, capacitors, packaging capacitor devices, etc., can solve problems such as low efficiency and low production speed, and achieve the effects of fast production speed, high production efficiency and high-efficiency production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

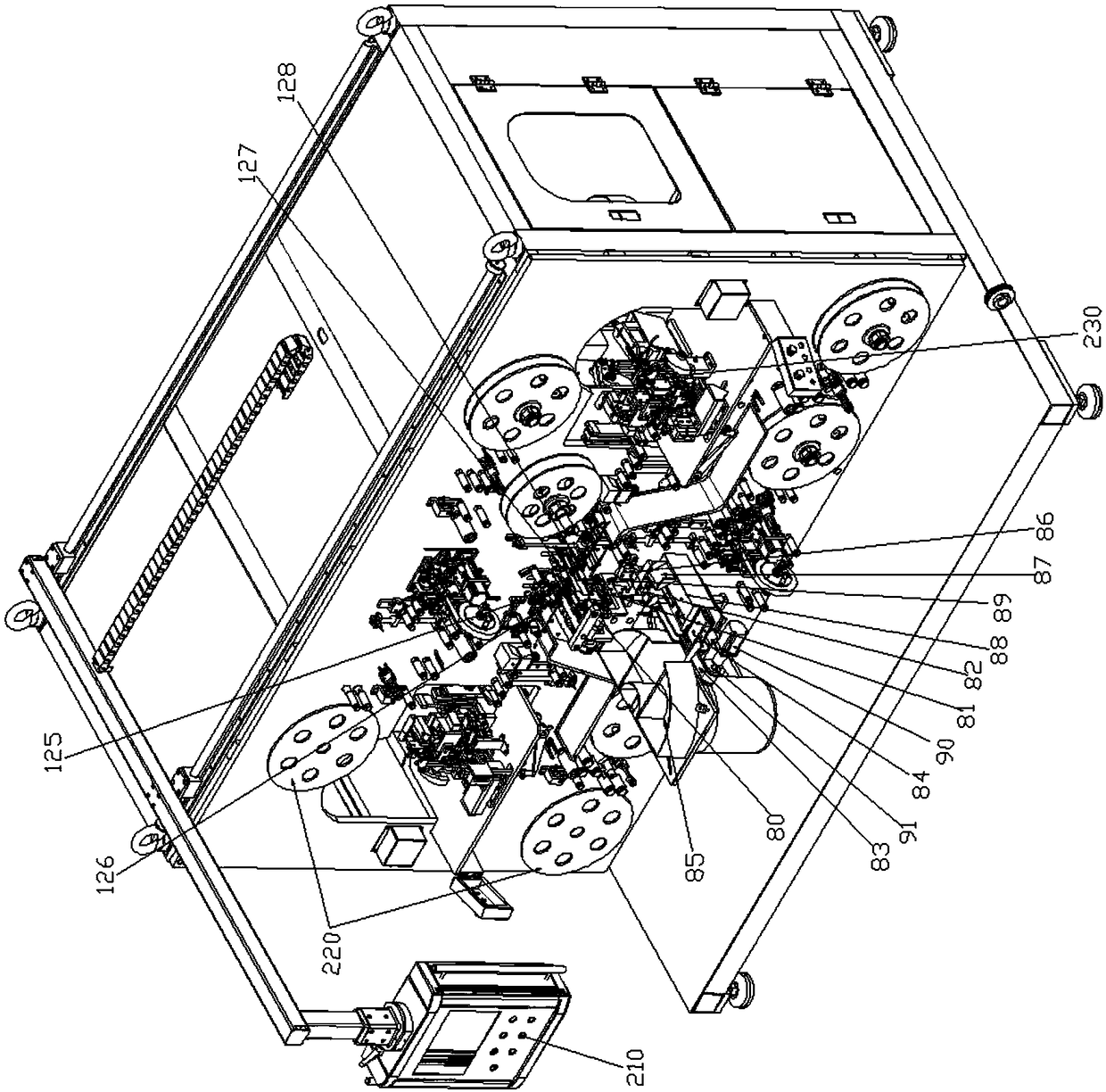

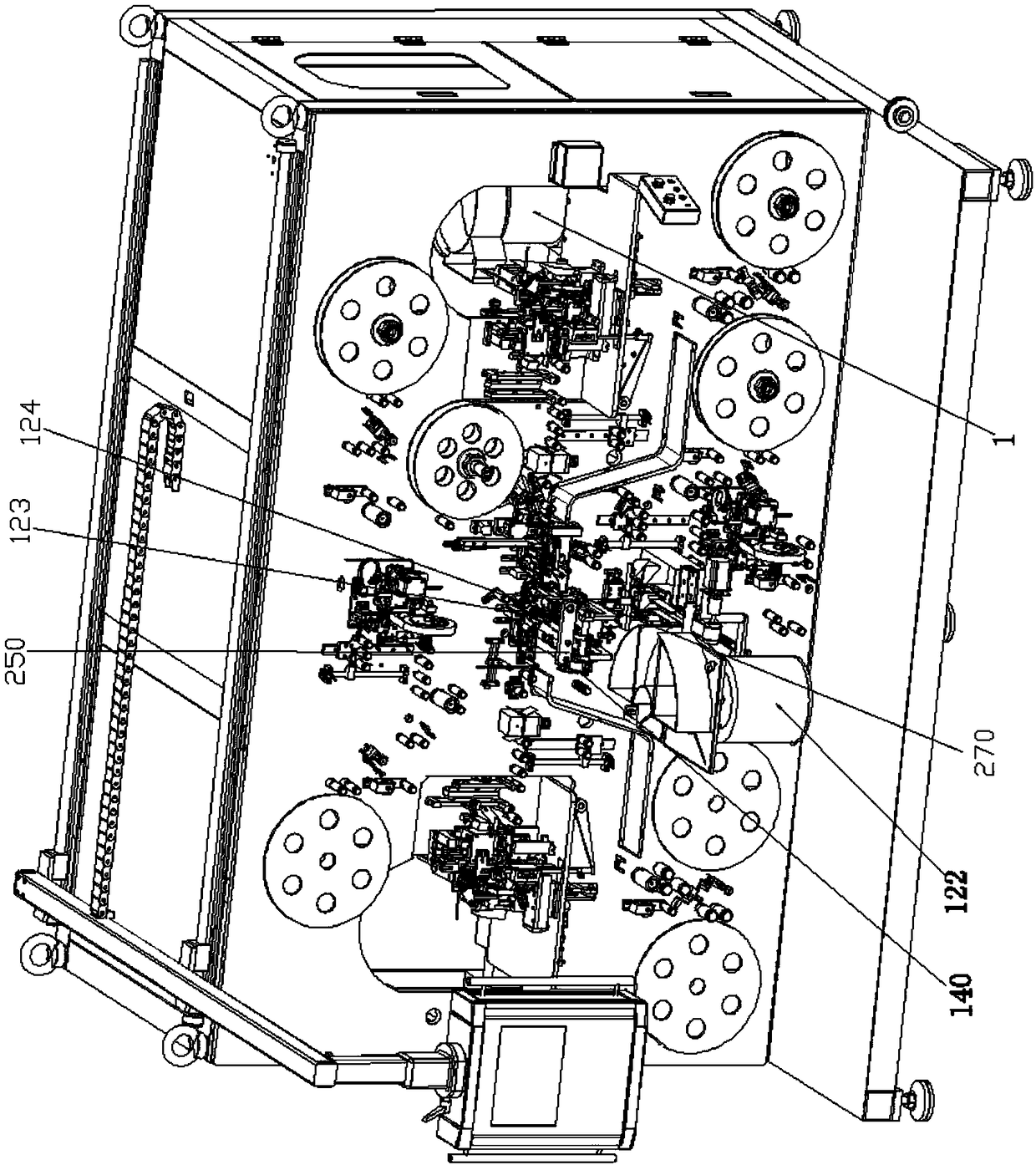

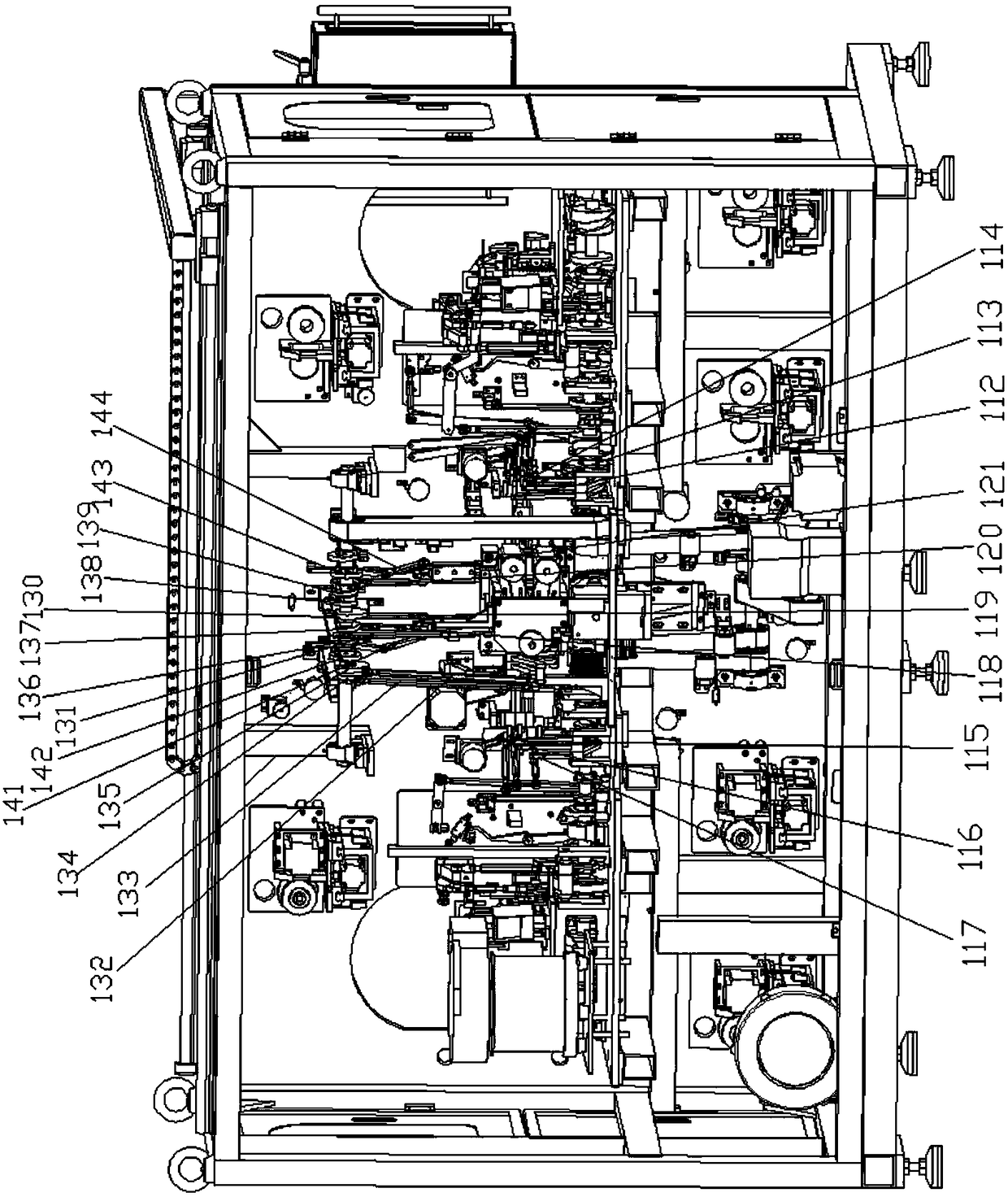

[0035] Please refer to Figure 1 to Figure 3 , the capacitor production equipment of this embodiment is a high-speed stitching and winding machine for manufacturing capacitors. The capacitor production equipment also includes a control system 210 , a sheet-making unit 220 , a winding unit 250 and a gluing unit 270 installed on the mounting board. The winding unit 250 includes a double-station winding mechanism and a material cutting mechanism. The film making unit includes a pole piece discharging mechanism, a chaff discharging mechanism, an electrolytic paper discharging mechanism and a chaff nailing mechanism 230 .

[0036] The chaff nailing mechanism 230 nails several pole pieces of the pole piece unwinding mechanism to the chaff of the chaff unwinding mechanism; the control system 210 is connected with the double-station winding mechanism. The double-station winding mechanism is equipped with a rotatable first station assembly and a second station assembly. The control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com