Punching method of low-plasticity high-silicon aluminum alloy strip

A high-silicon aluminum alloy and low plasticity technology, which is applied in the field of mechanical processing, can solve the problems of reducing the service life of punching dies, wearing the edge of punching dies, increasing punching costs, etc., to reduce strength, strengthen hydrostatic pressure, prevent The effect of cross-sectional cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Punching the high-silicon aluminum alloy strip with chemical composition Si 19wt%, Cu 4wt%, Fe 5.5wt%, Mg 1.5wt%, and the balance being Al, the specific process includes the following steps:

[0026] (1) Take a high-silicon aluminum alloy strip with a thickness t of 4.2mm and heat it to 320°C;

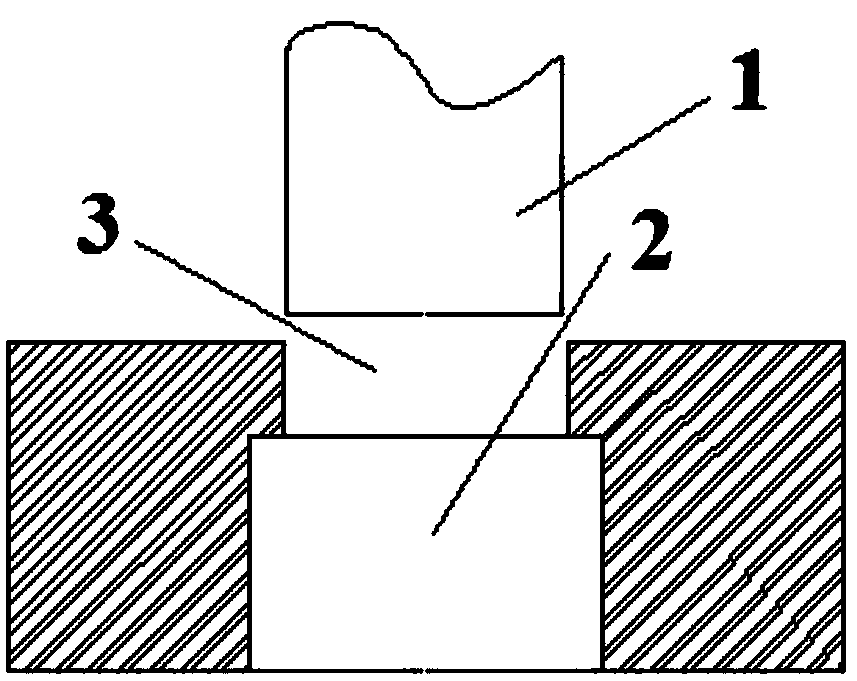

[0027] (2) Put the heated high-silicon aluminum alloy strip in the guide groove 3 of the punching die, guide and position the strip, and fix it with a pressing head, start the press, and set the punching die 2 and punch 1 Under the action of the cutting edge, the high silicon aluminum alloy strip is punched and blanked; the depth of the punching die guide groove 3 is 3.8mm, the gap between the die 2 and the punch 1 is 0.05mm, and the punching die blade The bottom of the mouth has small rounded corners, and the rounded corner radius r is 0.2mm;

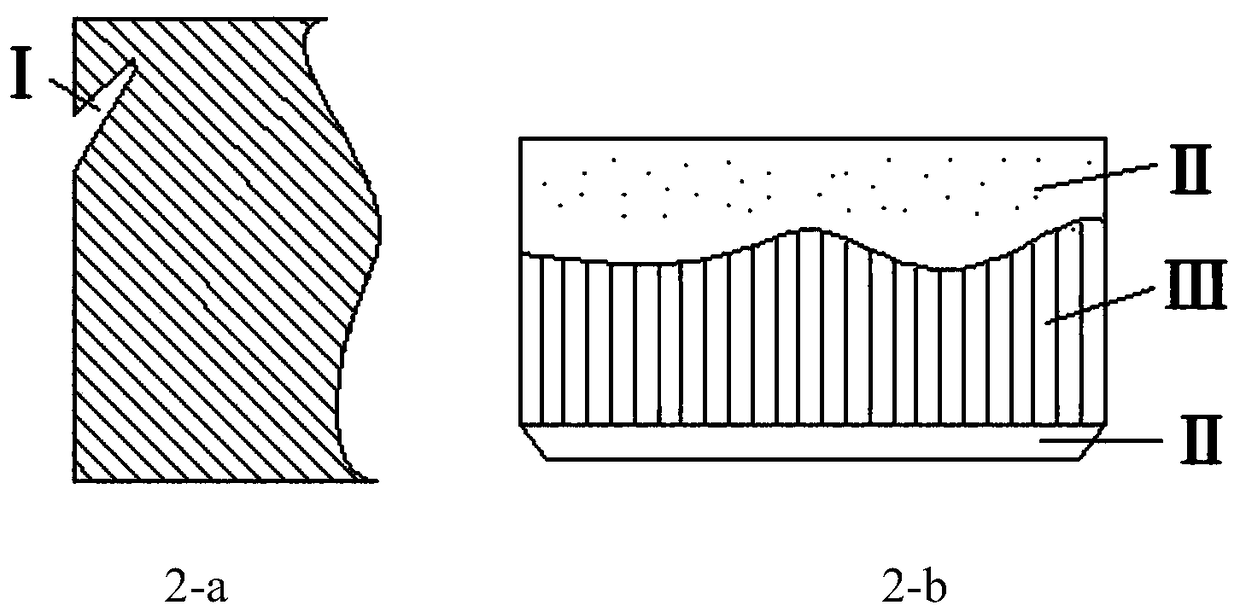

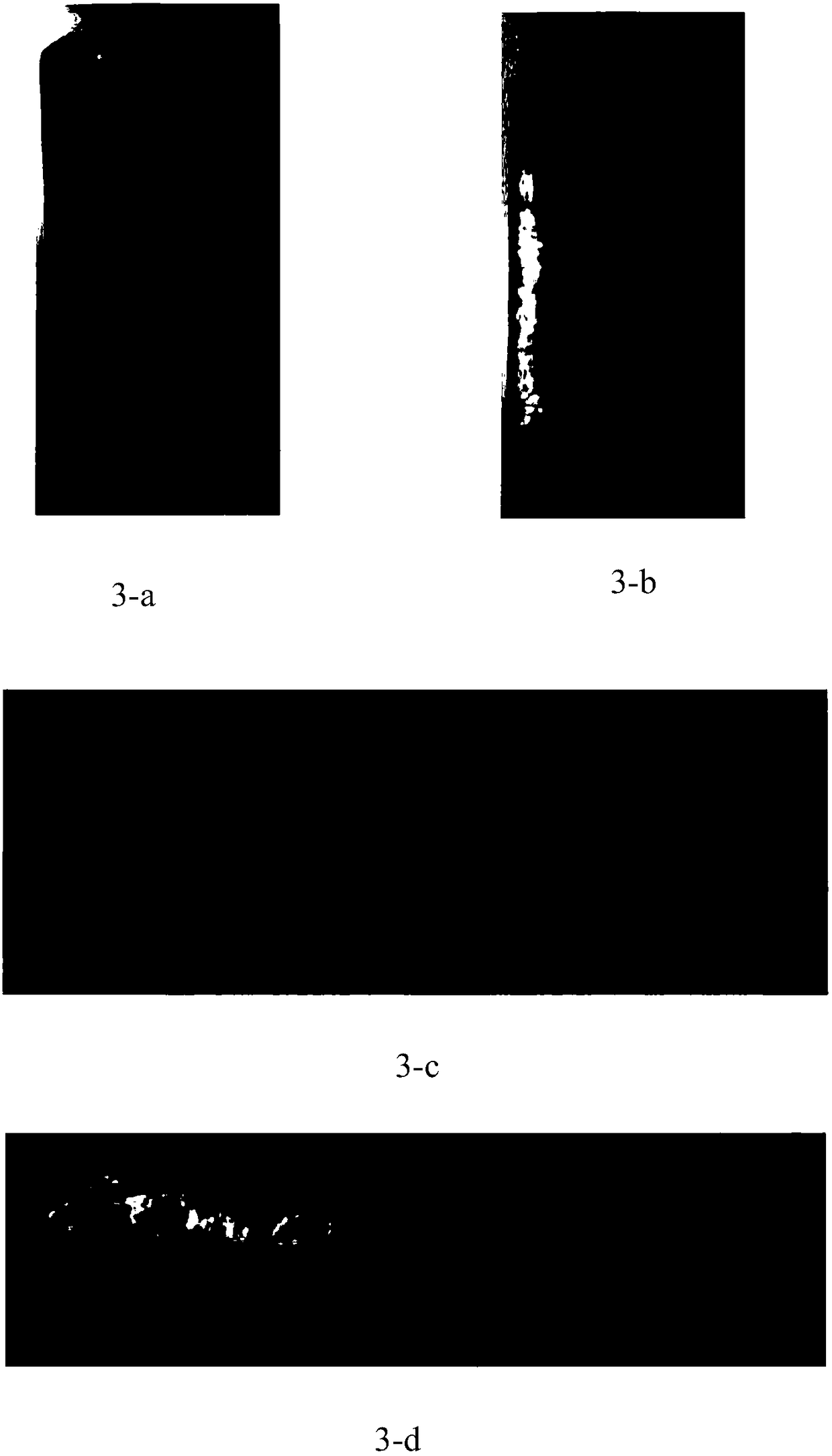

[0028] The cross-sectional effect diagram of the high silicon aluminum alloy strip obtained by the above punching method is as follows image...

Embodiment 2

[0030] Punching the high silicon aluminum alloy strip with chemical composition Si 16.8wt%, Cu 4.3wt%, Fe 5wt%, Mg 1.4wt%, and the balance being Al, the specific process includes the following steps:

[0031] (1) Take a high-silicon aluminum alloy strip with a thickness t of 5.5mm and heat it to 330°C;

[0032] (2) Put the heated high-silicon aluminum alloy strip in the guide groove of the punching die, guide and position the strip, and fix it with a pressing head, start the press, and set the punching die 2 and punch 1 Under the action of the cutting edge, the high silicon aluminum alloy strip is punched and blanked; the depth of the guiding groove 3 of the punching die is 5.3mm, the gap between the die 2 and the punch 1 is 0.07mm, and the cutting edge of the die The bottom is small rounded corners, and the rounded corner radius r is 0.5mm;

[0033] The cross-sectional effect diagram of the high silicon aluminum alloy strip obtained by the above punching method is as follows image...

Embodiment 3

[0035] Punching a high-silicon aluminum alloy strip with chemical composition Si 18wt%, Cu 3.5wt%, Fe 5wt%, Mg 1wt%, and the balance being Al, the specific process includes the following steps:

[0036] (1) Take a high-silicon aluminum alloy strip with a thickness t of 5mm and heat it to 300°C;

[0037] (2) Put the heated high-silicon aluminum alloy strip in the guide groove 3 of the punching die, guide and position the strip, and fix it with a pressing head, start the press, and set the punching die 2 and punch 1 Under the action of the cutting edge, the high-silicon aluminum alloy strip is punched and blanked; the depth of the punching die guide groove 3 is 4.4mm, the gap between the die 2 and the punch 1 is 0.06mm, and the punching die blade The bottom of the mouth is a small rounded corner, and the rounded corner radius r is 0.3mm;

[0038] The cross-sectional effect diagram of the high silicon aluminum alloy strip obtained by the above punching method is as follows image 3 As...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Corner radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com