A welding method for vertical vertical welding of high-strength steel components with robot twin wires

A welding method and high-strength steel technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve rare problems, achieve the effect of reducing width, ensuring welding quality, and avoiding molten pool flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, the double-wire pulse GMAW vertical welding method for high-strength steel components is carried out in the following steps:

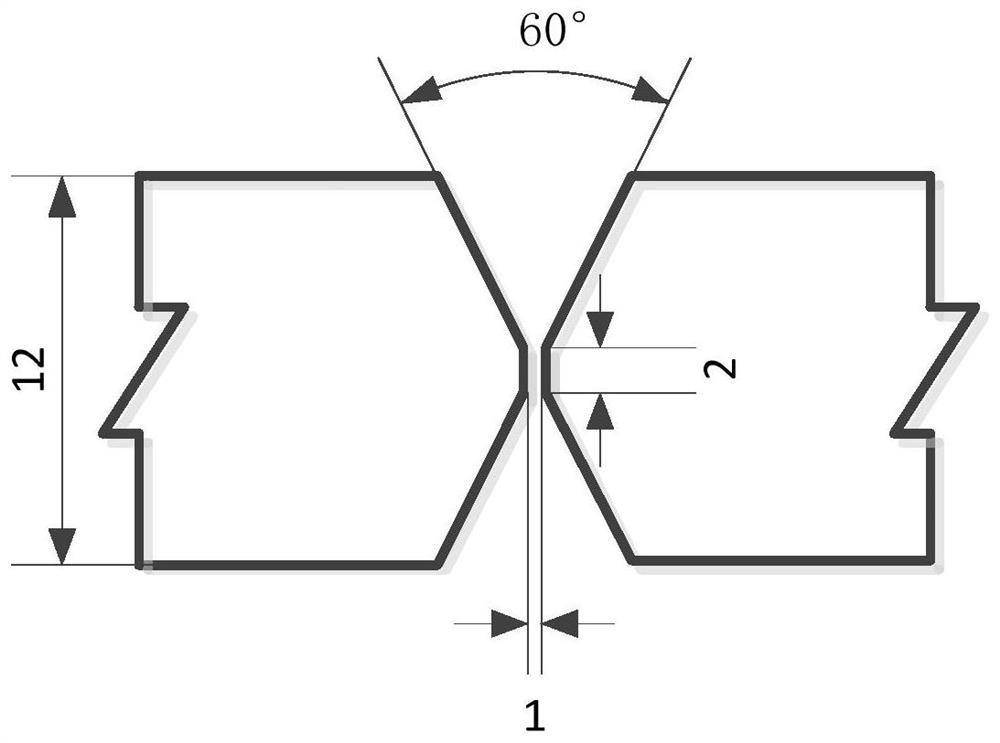

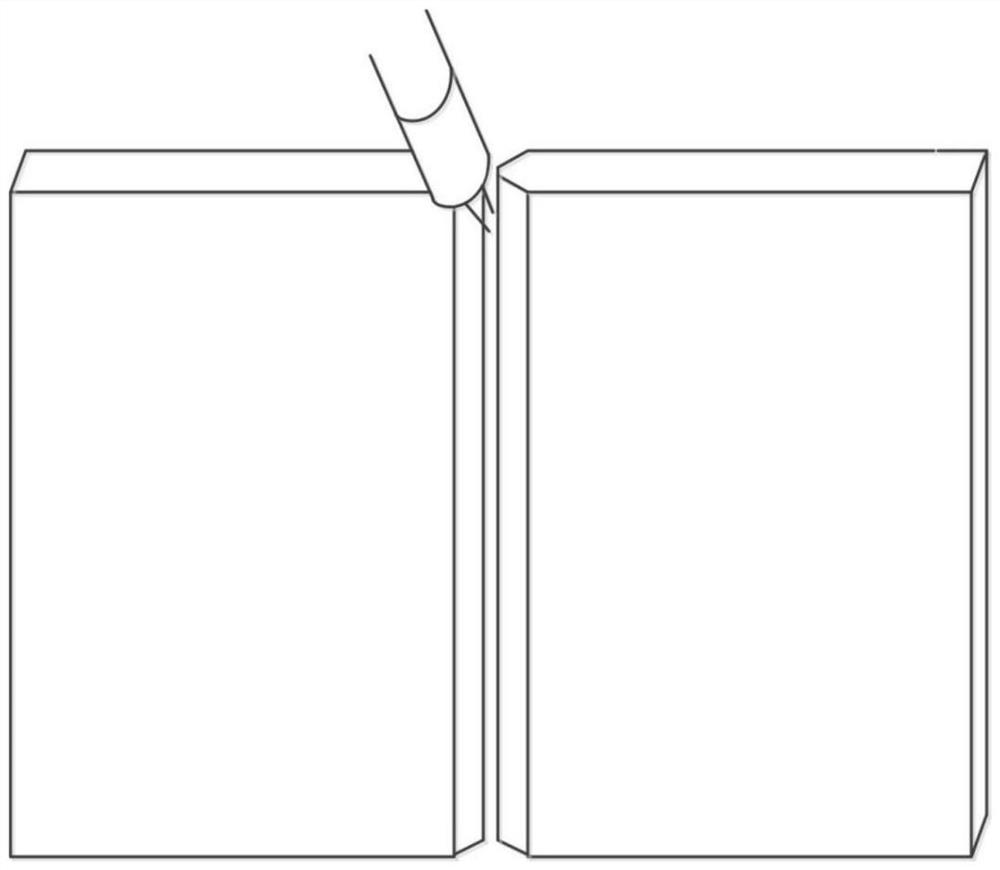

[0030] The workpiece to be welded is milled to produce an X-shaped welding groove, the groove angle is 60°, and the blunt edge is 2-4mm. The groove and the 30mm range on both sides of the inner and outer walls are cleaned until the metallic luster is exposed. The piece to be welded is a high-strength steel member, and its mass percentage composition is: C: 0.09%-0.14%, Si: 0.17%-0.37%, Mn: 0.20%-0.60%, S: ≤0.030%, P: ≤0.035%, Cr: 0.09%-1.20%, Ni: 2.60%-3.00%, Mo: 0.20%-0.27%, V: 0.04%-0.10%, the type of welding wire used is wm960, and the diameter is 1.2mm. Fix the workpiece to be welded by spot welding with GMAW, and the gap between the two plates is 1-2mm. Place the parts to be welded vertically and fix them with clamps. Use the double-wire pulse GMAW method to weld the bottom layer, filling layer and cover layer. The shi...

Embodiment 2

[0033] In this embodiment, the double-wire pulse GMAW vertical welding method for high-strength steel components is carried out in the following steps:

[0034] The workpiece to be welded is milled to produce an X-shaped welding groove, the groove angle is 60°, and the blunt edge is 2-4mm. The groove and the 30mm range on both sides of the inner and outer walls are cleaned until the metallic luster is exposed. The high-strength steel member to be welded is composed of: C: 0.09%-0.14%, Si: 0.17%-0.37%, Mn: 0.20%-0.60%, S: ≤0.030%, P: ≤0.035%, Cr : 0.09%-1.20%, Ni: 2.60%-3.00%, Mo: 0.20%-0.27%, V: 0.04%-0.10%, the type of welding wire used is carbon steel wire with a diameter of 1.2mm. Fix the workpiece to be welded by spot welding with GMAW, and the gap between the two plates is 1-2mm. Place the parts to be welded vertically and fix them with clamps. Use the double-wire pulse GMAW method to weld the bottom layer, filling layer and cover layer. The shielding gas used is a mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com