A processing method of complex special-shaped foil-shaped solder for waveguide antenna

A processing technology and a technology for a waveguide antenna, which are applied to the processing technology field of complex special-shaped foil-shaped solder for waveguide antenna, and can solve the problems of inability to process miscellaneous and fine foil-shaped solder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

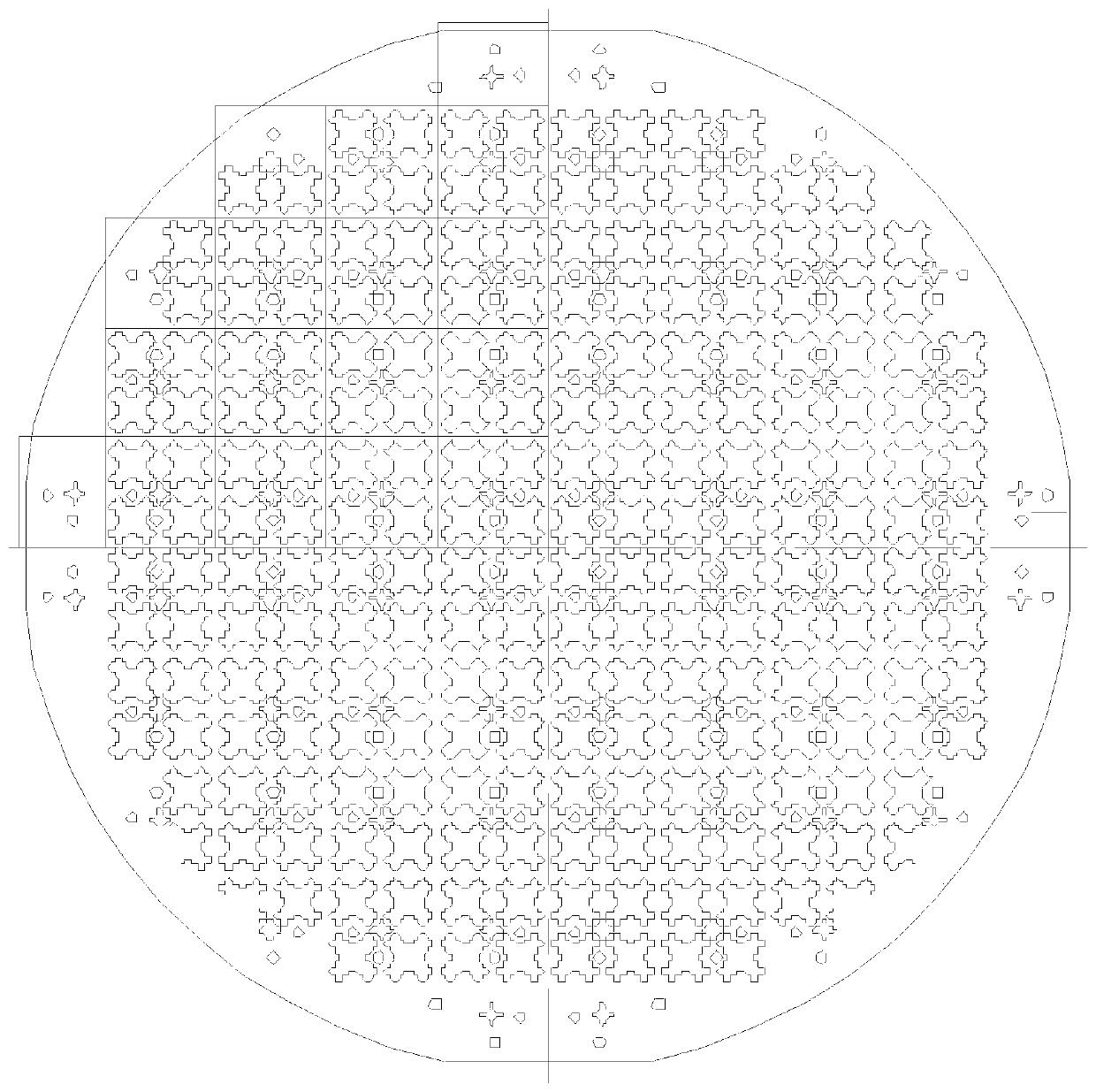

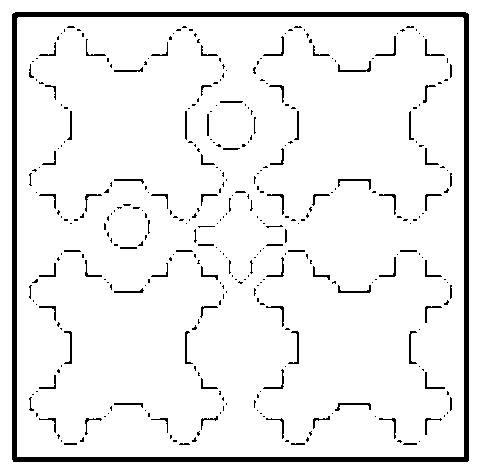

[0044] This method is used to domestically process the complex special-shaped foil-shaped brazing filler metal of an antenna. Typical Dimensions of Parts The minimum waveguide slot width is 0.5mm, and the minimum narrow rib wall width is 0.5mm. Among them, the complex special-shaped foil-shaped solder needs to be made into figure 1 The shape of the perimeter of the gap is shown.

[0045] Foil-shaped solder is easy to deform and has poor rigidity. In order to ensure accuracy, a low-stress processing scheme is used to avoid deformation. Considering the shape of the complex special-shaped foil-shaped solder, it should be consistent with the waveguide cavity and the periphery of the gap. A flattening process is added before processing to ensure the flatness of the raw material and the dimensional accuracy. Cut Al-Si-Mg foil-shaped solder with a thickness of 0.05mm into several pieces of 140×280, use a flat plate to flatten the solder in an oven, heat at 100°C, and hold for 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com