Rumination type plastic extruder screw and material extruding method

A screw and plastic technology, which is applied in the field of ruminant plastic extruder screw and extrusion material, can solve the problems of increasing processing difficulty, wasting length-to-diameter ratio, excessive shearing of plastic, etc., to reduce material cost and processing cost, and reduce decomposition chance, the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

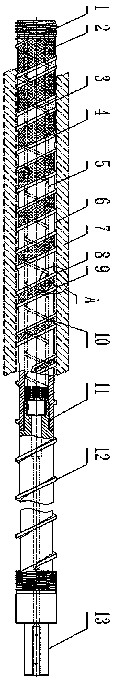

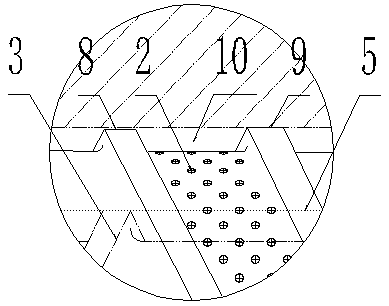

[0012] Embodiment 1: with reference to attached figure 1 with 2 . A ruminant type plastic extruder screw, the screw is composed of a female screw 4 and a sub-screw 3, the melting section 6 of the front section of the female screw 4 is a hollow screw barrel, and the rear delivery section is a solid section with a power connection shaft, and the sub-screw is concentric The form of circle is packed in the hollow screw barrel 5 of female screw rod 4. The hollow section of the female screw rod is provided with additional threads 8 to form additional thread grooves 10, and the bottom of the thread grooves is provided with through holes or long holes 2 at a certain density to form a sieve-shaped bottom groove. The female screw rod 4 is designed as a cantilever beam type, installed in the main screw barrel 7, and the tail is installed in the thrust bearing of the power source reduction box. Sub-screw 3 is an inverted reverse screw. The front end of the sub-screw 3 is connected to ...

Embodiment 2

[0013] Embodiment 2: On the basis of embodiment 1, a kind of extruding method of ruminant type plastic extruder screw. The female screw 4 of right-handed thread rotates counterclockwise when viewed from the right end to the left, and the plastic raw material therein is pushed to the left end by the right-handed thread of female screw 4. Under the dual action of external heat source and self-shear heat, it enters the melting section 6 (hollow section) and begins to melt gradually, and the partially melted raw material enters the additional screw groove 10 through the gap of the additional screw thread, and the unmelted raw material continues to be conveyed forward and continues Melting, until the front end is completely melted and all enter the additional screw, the molten raw material entering the additional screw groove 10 forms a high pressure under the action of the rotating screw, forcing the molten raw material to enter the sub-screw 3 through the sieve-like groove bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com