Slump prevention type efficient water reducer and production process thereof

A high-efficiency water reducer and production process technology, applied in the field of water reducer and its production process, can solve the problems of fusion of slump retaining agent and water reducer, short slump retaining time, short transportation distance, etc., to reduce bleeding, Increase fluidity and improve the effect of water reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

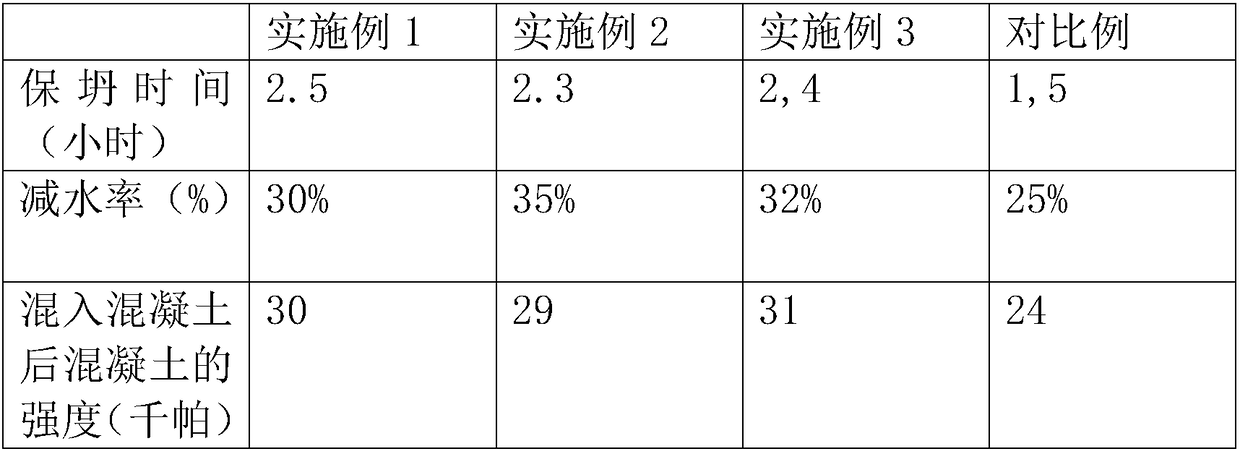

Examples

Embodiment 1

[0040] S1: Add 1800 kg of water to the 5000L reactor, then add 1800 kg of imported ether, start stirring to dissolve the ether, add 20 kg of acrylic acid after dissolving, continue stirring for 10 minutes, then add 10 kg of 27.5% hydrogen peroxide, then add 20 kg of water to rinse and add hydrogen peroxide pipe, and stir for 5 minutes. Whole reaction temperature is controlled at 45 ℃.

[0041] S2: Material A is prepared by dissolving 92 kg of acrylic acid in 350 m of water and stirring. Because too early or too late will lead to insufficient reaction, in order to avoid affecting the product quality, material A is prepared 15 minutes before the dropwise addition.

[0042] Material B is prepared by dissolving 2.5 kg of thioglycolic acid in 500 kg of water and stirring. Because too early or too late will lead to insufficient reaction, in order to avoid affecting the product quality, material B is also prepared 15 minutes before the dropwise addition.

[0043] S3: Extract the p...

Embodiment 2

[0048] S1: Add 1750 kg of water to the 5000L reactor, then add 1700 kg of imported ether, start stirring to dissolve the ether, add 15 kg of acrylic acid after dissolving and continue stirring for 10 minutes, then add 5 kg of 27.5% hydrogen peroxide, then add 20 kg of water to rinse and add hydrogen peroxide pipe, and stir for 5 minutes. Whole reaction temperature is controlled at 20 ℃.

[0049] S2: Material A is prepared by dissolving 80 kg of acrylic acid in 400 m of water and stirring. Because too early or too late will lead to insufficient reaction, in order to avoid affecting the product quality, material A is prepared 15 minutes before the dropwise addition.

[0050] Material B is prepared by dissolving 2.4 kg of thioglycolic acid in 450 kg of water and stirring. Because too early or too late will lead to insufficient reaction, in order to avoid affecting the product quality, material B is also prepared 15 minutes before the dropwise addition.

[0051] S3: Extract the...

Embodiment 3

[0056] S1: Add 1,900 kg of water to a 5,000L reactor, then add 1,850 kg of imported ether, start stirring to dissolve the ether, add 25 kg of acrylic acid and continue stirring for 10 minutes, then add 12 kg of 27.5% hydrogen peroxide, then add 20 kg of water to rinse and add hydrogen peroxide pipe, and stir for 5 minutes. Whole reaction temperature is controlled at 30 ℃.

[0057]S2: Material A is prepared by dissolving 80 kg of acrylic acid in 350 m of water and stirring. Because too early or too late will lead to insufficient reaction, in order to avoid affecting the product quality, material A is prepared 15 minutes before the dropwise addition.

[0058] Material B is prepared by dissolving 2.3 kg of thioglycolic acid in 500 kg of water and stirring. Because too early or too late will lead to insufficient reaction, in order to avoid affecting the product quality, material B is also prepared 15 minutes before the dropwise addition.

[0059] S3: Extract the prepared materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com