Coiled tubing with on-line continuous production and dynamically adjustable performance and preparation method thereof

A technology for oil tubing and performance, which is applied in the field of coiled tubing and its preparation, can solve the problems of increasing the cost of raw materials, reducing the inner diameter of the coiled tubing and liquid pumping capacity, sacrificing the overall strength and fatigue life of the coiled tubing, and achieving the elimination of bad tissue and durability Excellent corrosion performance and good fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

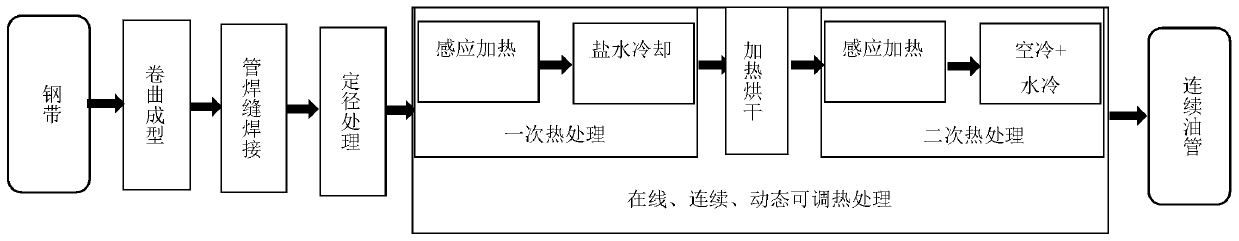

Method used

Image

Examples

Embodiment 1

[0036] According to mass percentage, the chemical composition of the steel used in this embodiment is C 0.17%, Mn 1.5%, P 0.01%, S 0.003%, Si 0.33%, B 0.0005%, and Fe balance. Through microalloying, adding Nb, V or Ti alloying elements, hot rolling to obtain a ferrite + pearlite balance structure with a grain size of 13, after rolling, the steel coil is sheared to obtain a 2.000in*0.175in continuous pipe steel belt.

[0037] Cut the end of the steel strip obliquely at 45° and process I-shaped bevel, and assemble it to prepare for welding. The steel strip welding is completed by plasma welding. After welding, the welding seam reinforcement is removed by grinding, and the welding seam is heated to 550 ° C and air-cooled. Post-weld heat treatment. Complete the butt joint of all steel strip welds according to the above process, and obtain a steel strip with a total length of 4300m.

[0038] The steel strip with a length of 4300m enters the pipe making unit at a speed of 12m / min ...

Embodiment 2

[0043] According to mass percentage, the chemical composition of the steel used in this embodiment is C 0.22%, Mn 1.2%, P 0.01%, S 0.002%, Si 0.15%, Mo 0.25%, B 0.0007%, and Fe balance. Through microalloying, adding Nb, V or Ti alloying elements, hot rolling to obtain a ferrite + pearlite balance structure with a grain size of 13, after rolling, the steel coil is sheared to obtain a 2.000in*0.204in continuous pipe steel belt. Cut the end of the steel strip obliquely at 45° and process I-shaped groove, and assemble it to prepare for welding. TIG welding is used to complete the welding of the steel strip. After welding, the welding seam reinforcement is removed by grinding, and the welding seam is heated to 480°C and air-cooled. Post-weld heat treatment. Complete the butt joint of all steel strip welds according to the above process, and obtain a steel strip with a total length of 3600m.

[0044] The steel strip with a length of 3600m enters the pipe making unit at a speed of ...

Embodiment 3

[0049] According to the mass percentage, the chemical composition of the steel used in this example is C 0.33%, Mn 1.8%, P0.02%, S 0.005%, Si 0.5%, Mo 0.20%, Cr 1.4%, Ni0.05%, Fe balance . Through microalloying, adding Nb, V or Ti alloying elements, hot rolling to obtain a ferrite + pearlite balance structure with a grain size of 14, after rolling, the steel coil is sheared to obtain a 2.000in*0.156in continuous pipe. steel belt. Cut the end of the steel strip obliquely at 45° and process I-shaped groove, and assemble it to prepare for welding. The steel strip is welded by MIG welding. After welding, the welding seam reinforcement is removed by grinding, and the welding seam is heated to 960°C and air-cooled. Post-weld heat treatment. Complete the butt joint of all steel strip welds according to the above process, and obtain a steel strip with a total length of 5500m.

[0050] The steel strip with a length of 5500m enters the pipe making unit at a speed of 14m / min from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com