Magnetic leakage, electromagnetic ultrasonic and vertex compound pipeline external detection probe

An electromagnetic ultrasonic and eddy current testing technology, which is applied in the direction of electromagnetic measuring devices, using electromagnetic means, electric/magnetic thickness measurement, etc., to achieve the effect of convenient operation, simple probe structure and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

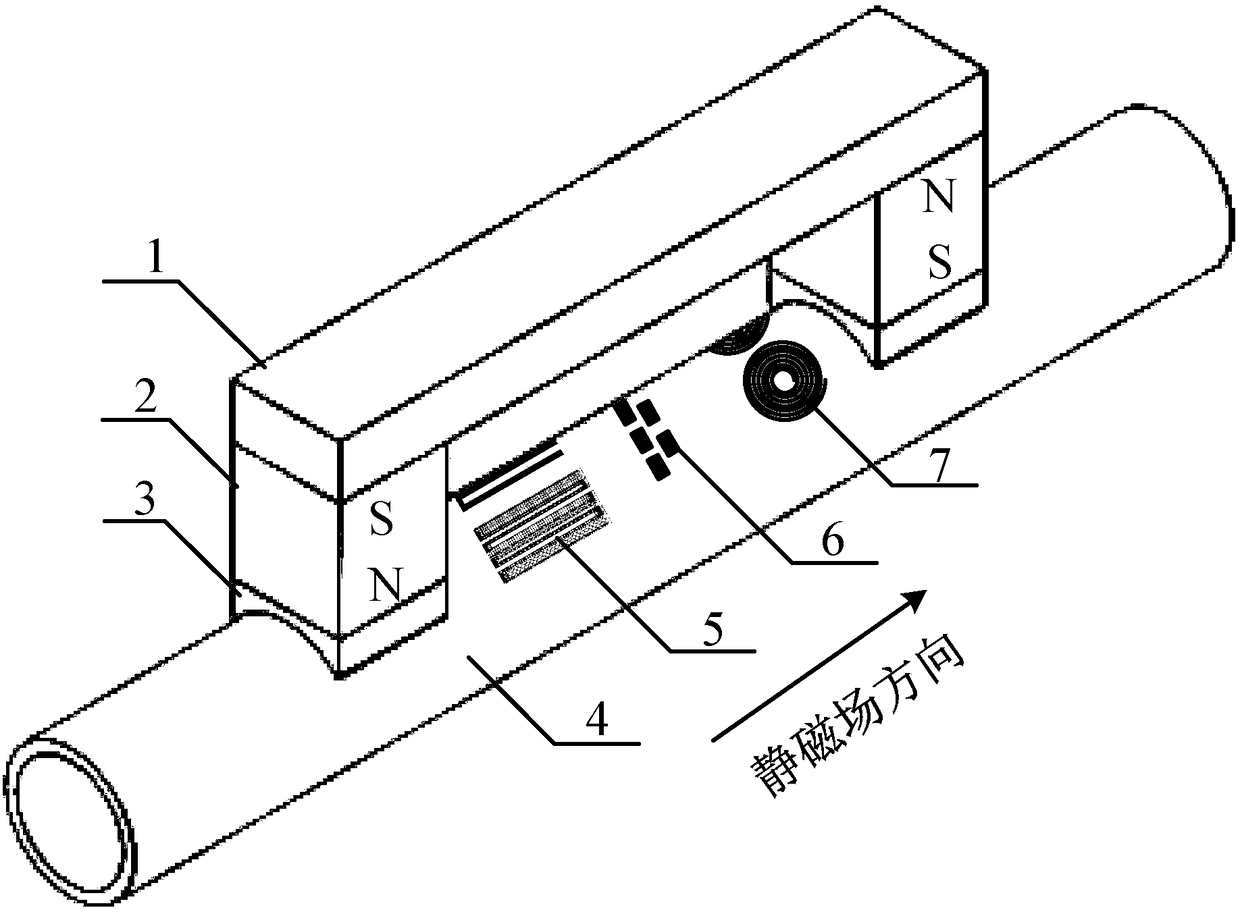

[0033] Specific implementation mode one: refer to figure 1 Specifically explain this embodiment, a magnetic flux leakage, electromagnetic ultrasonic and eddy current composite pipeline external detection probe described in this embodiment, which includes a magnetic flux leakage detection module, an electromagnetic ultrasonic detection module and an eddy current detection module;

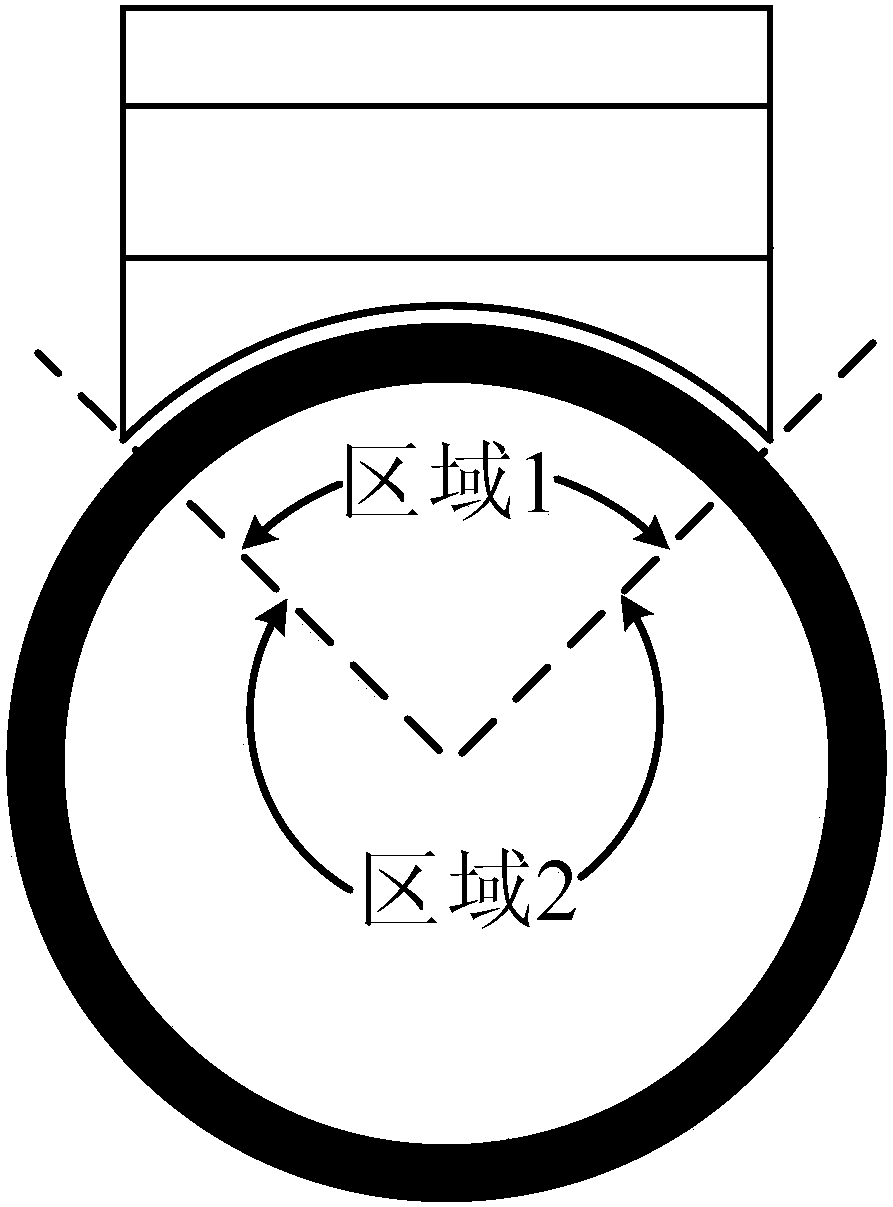

[0034] The magnetic flux leakage detection module includes: a U-shaped magnetic circuit and a plurality of magnetic sensitive elements 6, the U-shaped magnetic circuit is used to excite an axial static magnetic field in the pipeline 4 to be tested, and the plurality of magnetic sensitive elements 6 are arranged in a multi-channel staggered array Fixed on the surface of the tested pipeline 4 and located at the center of the U-shaped magnetic circuit, a plurality of magnetic sensitive elements 6 are used to detect the volume defect and the circumferential direction of the tested pipeline 4 within the ci...

specific Embodiment approach 2

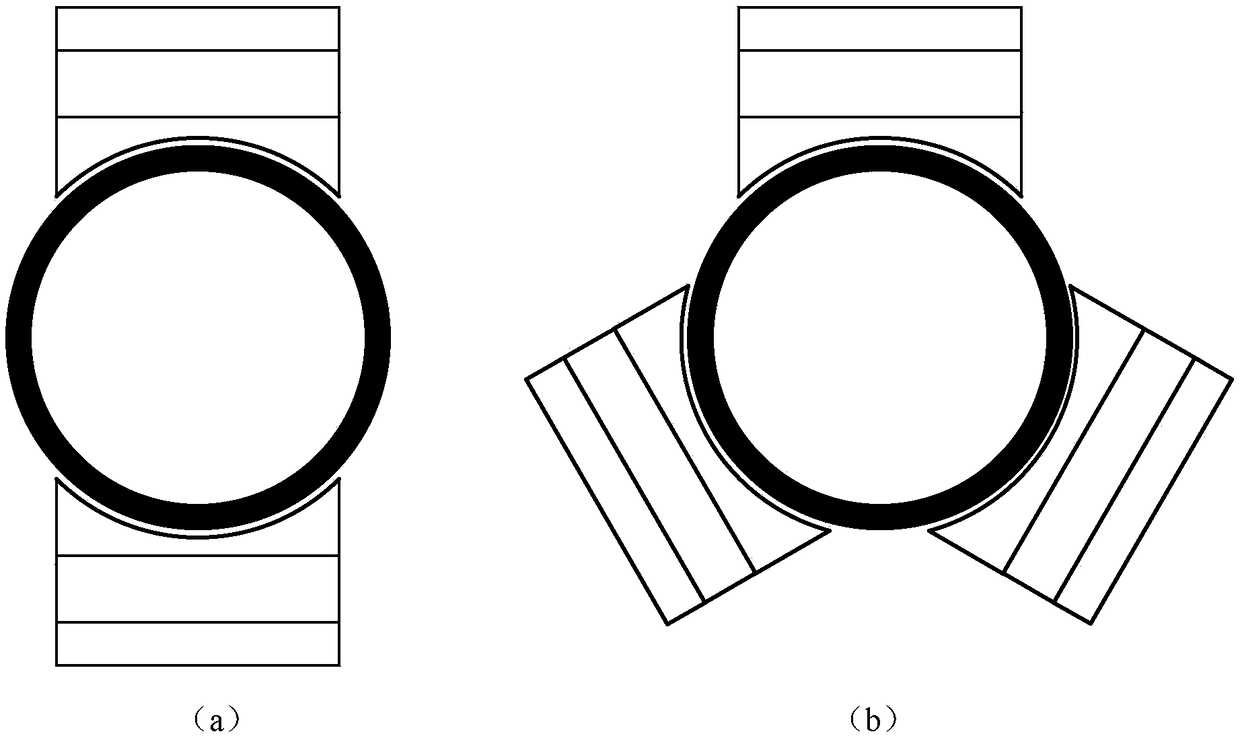

[0039] Specific embodiment 2: This embodiment is a further description of a kind of magnetic flux leakage, electromagnetic ultrasonic and eddy current composite pipeline external detection probe described in specific embodiment 1. In this embodiment, the U-shaped magnetic circuit includes: armature 1, Two magnets 2 and two pole pieces 3; the ends of the pole pieces 3 are set to a curved surface structure that fits the surface of the measured pipeline 4;

[0040] The armature 1 is overlapped at one end of the two magnets 2 at the same time, and the two pole pieces 3 are respectively located at the other ends of the two magnets 2. The armature 1 and the two pole pieces 3 rely on the suction force of the two magnets 2 to attract the two magnets 2 respectively. , and the magnetic poles of the two magnets 2 are opposite, so that the armature 1, the two magnets 2 and the two pole pieces 3 are combined to form a U-shaped magnetic circuit.

[0041] In practical application, two pole p...

specific Embodiment approach 3

[0042] Specific embodiment three: This embodiment is to further explain a kind of magnetic flux leakage, electromagnetic ultrasonic and eddy current composite pipeline external detection probe described in specific embodiment two. In this embodiment, the materials of the armature 1 and the pole piece 3 are Ferromagnetic material, the magnet 2 is a permanent magnet or an electromagnet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com