Product relevant with cement stabilized recycled aggregate

A technology for recycled aggregates and products, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as difficult to master the ratio, environmental resource burden, complex production process, etc., to save natural resources, Save raw material costs, good waste recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In a specific embodiment, the technical solution of this product can be implemented in the following ways:

[0031] (1) Raw materials

[0032] 1. Cement

[0033] The unit chooses P.S32.5 slag portland cement to produce this product, and conducts sampling inspection according to the test frequency of the "Regulations on the Quality Management of Inorganic Binder Stable Materials" compiled by the Road Engineering Quality Supervision Station to ensure that the cement quality meets the design requirements.

[0034] 2. Aggregate

[0035] (1) The aggregates of this product are recycled aggregates from construction waste crushed and screened, which are required to be clean and free of sundries.

[0036] (2) The aggregate crushing value is not more than 20%, and the needle flake content is not more than 3%.

[0037] The test frequency of the "Regulations on the Quality Management of Inorganic Binder Stable Materials" compiled by the Road Engineering Quality Supervision Stati...

Embodiment 2

[0059] The technical solution of this product can also be realized in the following ways:

[0060] (1) Raw materials

[0061] 1. Cement

[0062] The unit chooses P.S.B32.5 slag Portland cement to produce this product, and conducts sampling inspection according to the test frequency of the "Inorganic Binder Stable Material Quality Management Regulations" compiled by the Road Engineering Quality Supervision Station to ensure that the cement quality meets the design requirements.

[0063] 2. Aggregate

[0064] (1) The aggregates of this product are recycled aggregates from construction waste crushed and screened, which are required to be clean and free of sundries.

[0065](2) The aggregate crushing value is not more than 20%, and the needle flake content is not more than 3%, and the entry into the site is carried out according to the test frequency of the "Quality Management Regulations for Inorganic Binder Stable Materials" compiled by the Beijing Road Engineering Quality Sup...

Embodiment 3

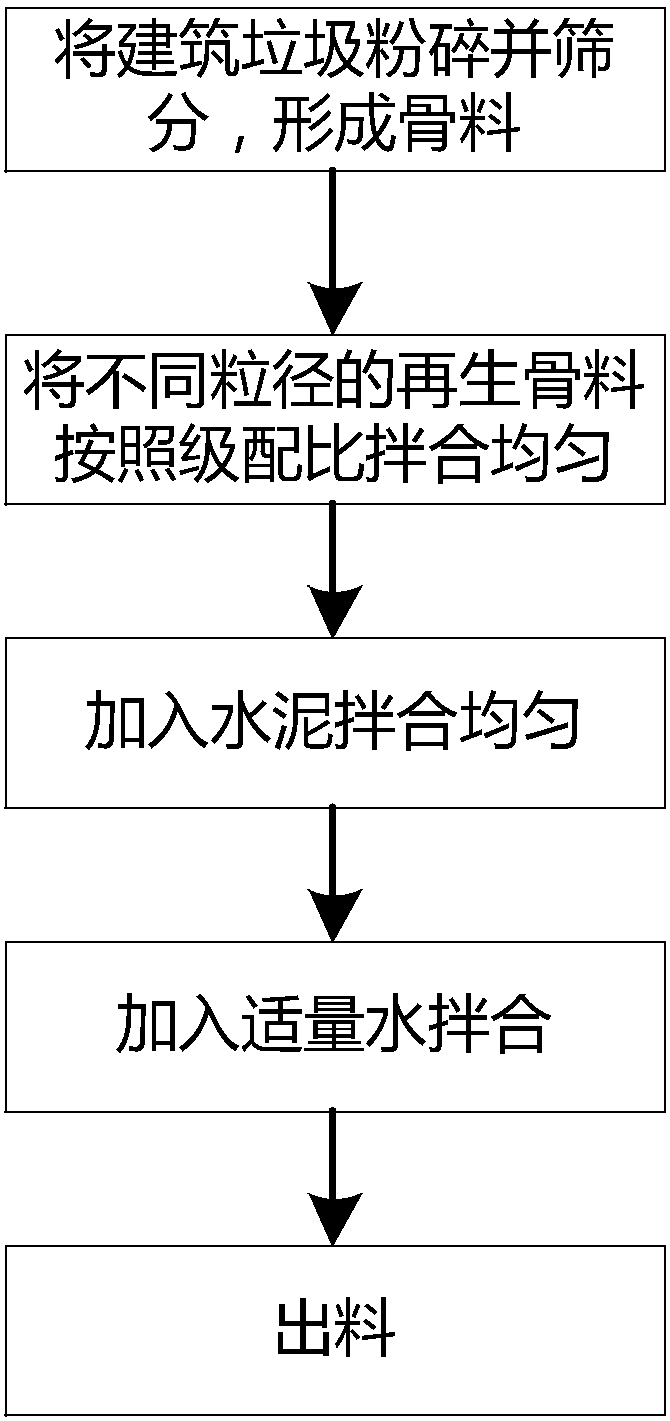

[0085] combine figure 1 , in yet another specific embodiment, the production process of the product is as follows:

[0086] 1) Pulverize the construction waste materials and sieve them according to particle size specifications to obtain recycled aggregates;

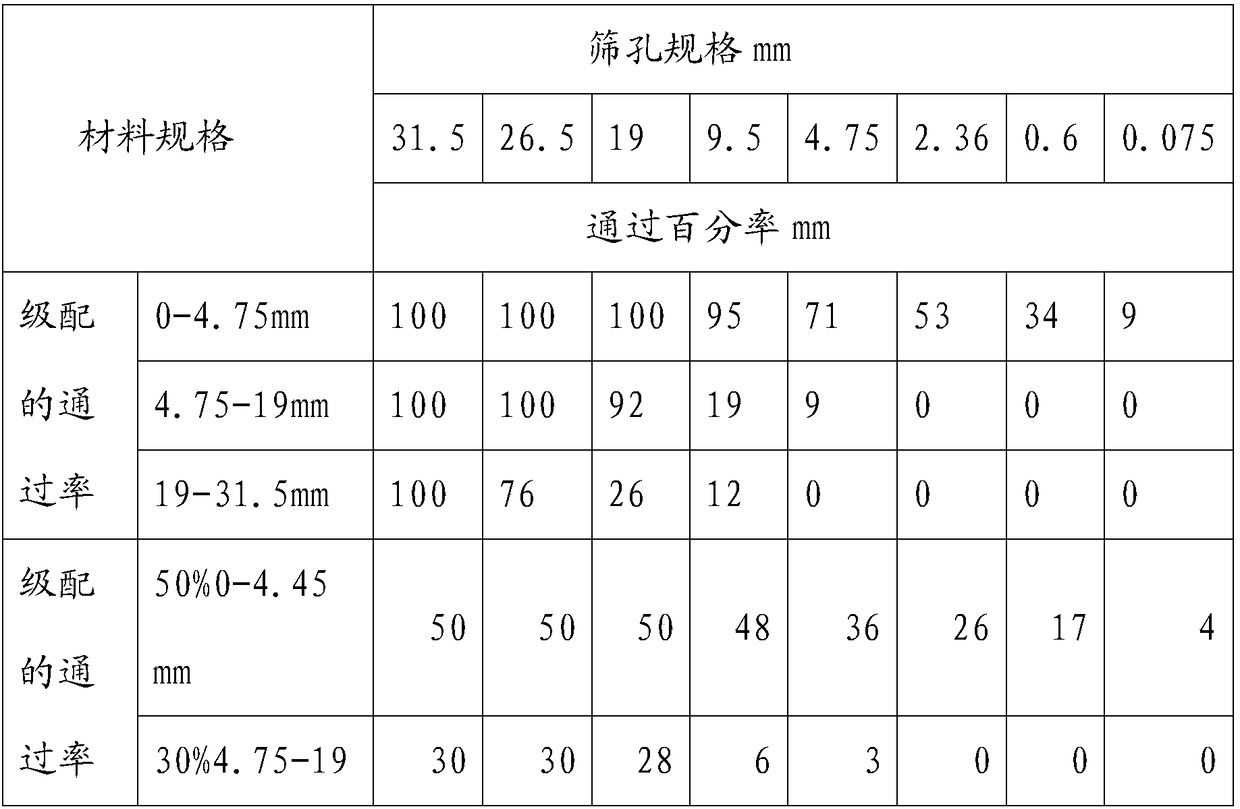

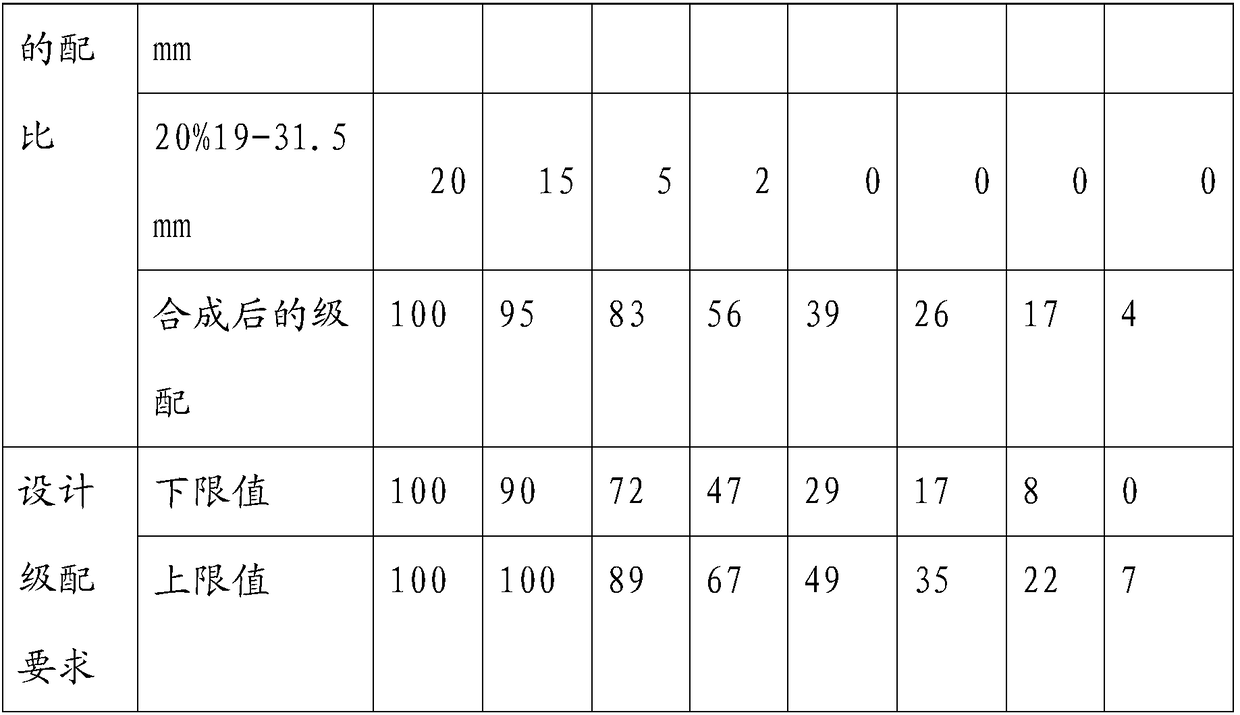

[0087] 2) Mix different particle sizes of the recycled aggregate according to the ratio of the number of aggregates and mix them evenly;

[0088] 3) Mix the uniformly mixed aggregate and cement in step 2) according to the mixing ratio;

[0089] 4) Add an appropriate amount of water to the mixed material in step 3), and after mixing evenly, the mixed material is required to be clean, free of impurities, uniform, and free of segregation;

[0090] 5) Discharging to form a recycled product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com