Smoke recirculation system applying high-temperature efficient cyclone separator

A cyclone separator and recirculation system technology, applied in the direction of flue gas combustion, non-flammable liquid/gas transportation, combustion methods, etc., can solve the problems of wear and tear of circulating fans, achieve stable eddy current, realize gravity sedimentation, and reduce wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

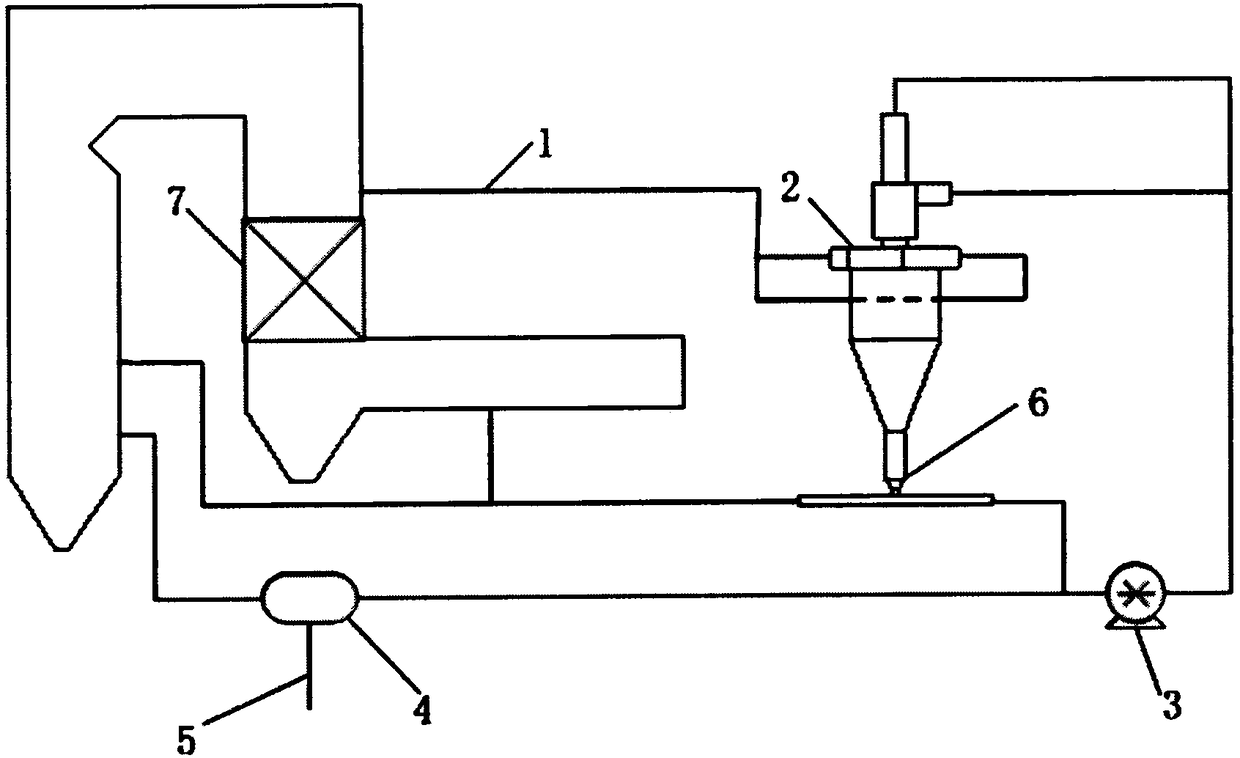

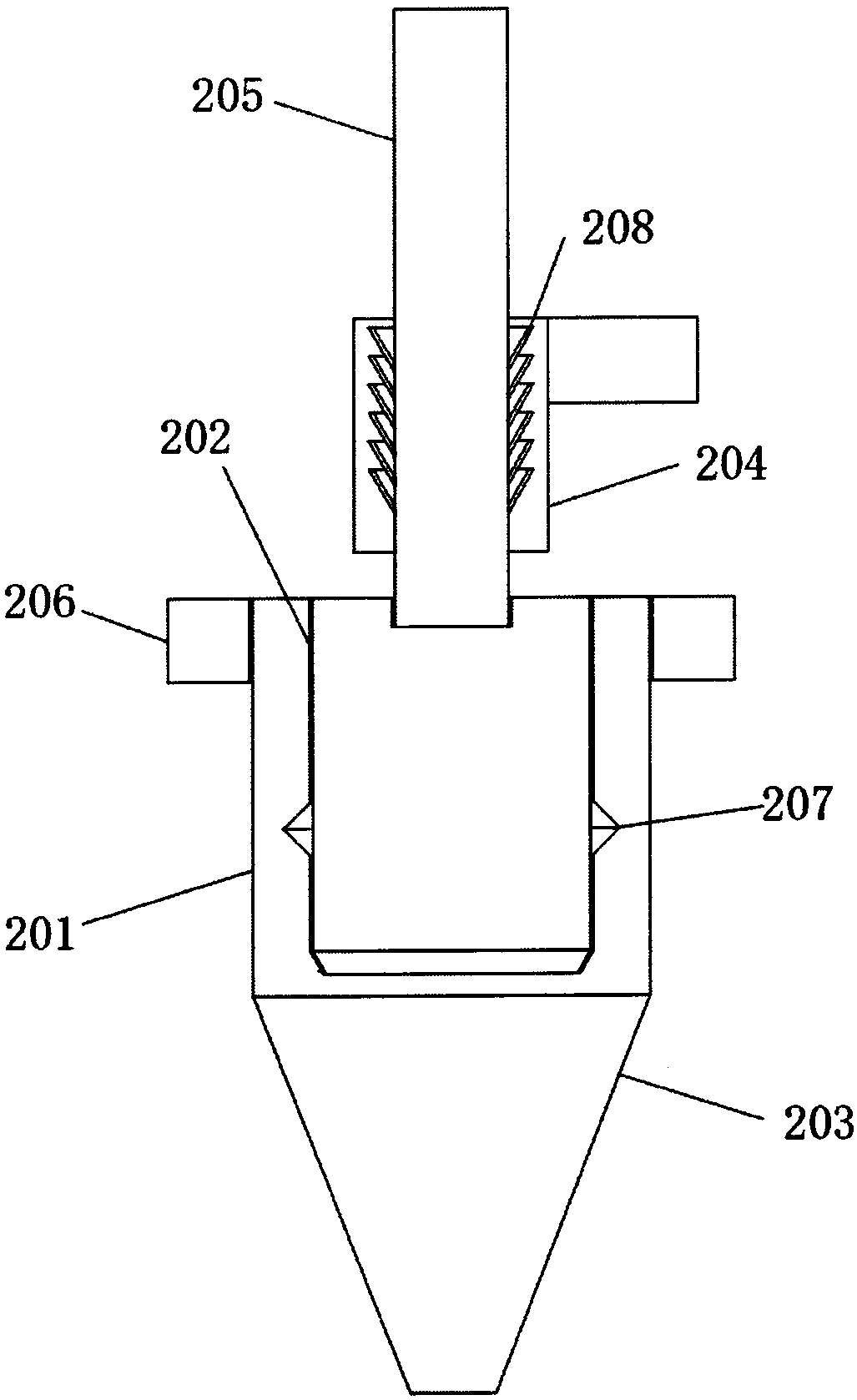

[0027] Such as figure 1 , 2 As shown, a flue gas recirculation system using a high-temperature high-efficiency cyclone separator provided by the present invention includes a boiler connected in sequence through a flue gas recirculation pipeline 1, a high-temperature high-efficiency cyclone separator 2, a circulating fan 3, a The mixing device 4 of the pure oxygen pipeline 5, the dust outlet of the high-temperature high-efficiency cyclone separator 2 is connected to the ash storage bin 6 of the cyclone separator, and the ash separated from the outlet of the ash storage bin 6 enters the boiler through the blowing action of the circulating fan 3; The outlet end of the circulating fan 3 is respectively connected to the mixing device 4 and the ash storage bin 6 of the cyclone separator. The mixing device 4 is connected to the boiler burner of the boiler, and the ash storage bin 6 of the cyclone separator is respectively connected to the furnace of the boiler and the tail flue of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com