Farmland arable layer used plastic film collector

A recycling machine and plowing layer technology, applied in the field of agricultural machinery, can solve problems such as limited recycling, poor operation results, and shedding of residual film, and achieve the effects of strong pertinence, convenient adjustment, and sufficient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described in detail below in conjunction with specific examples.

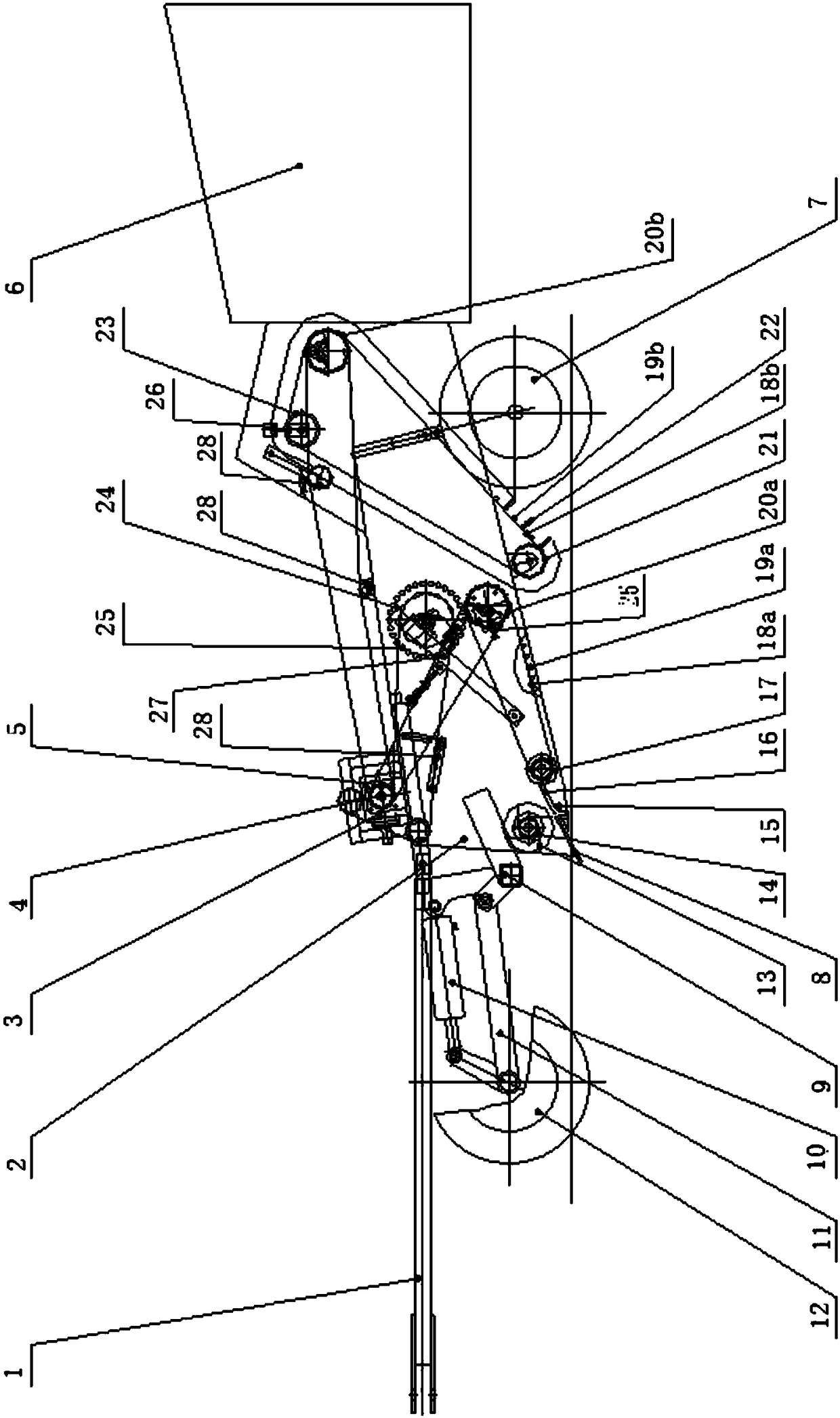

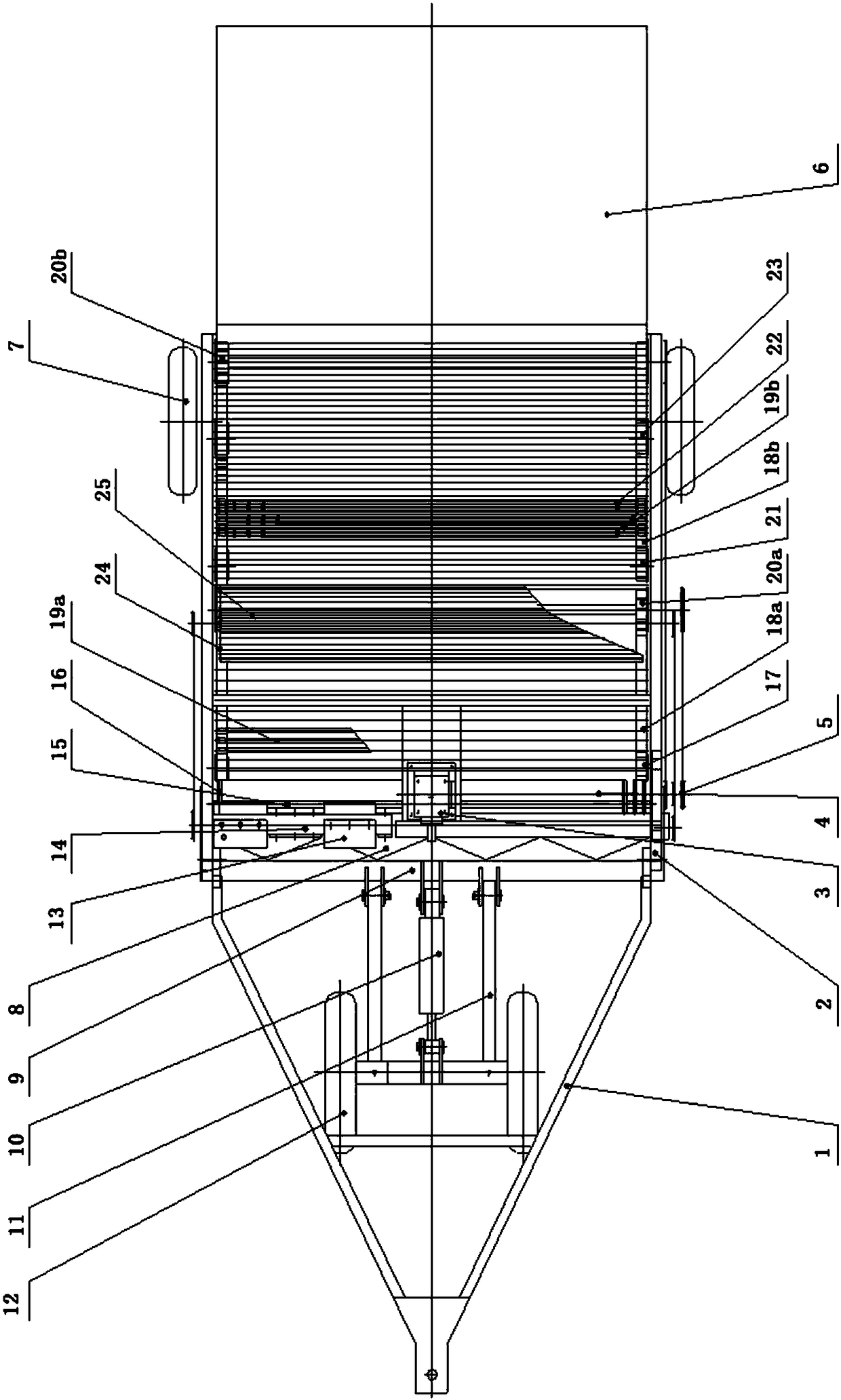

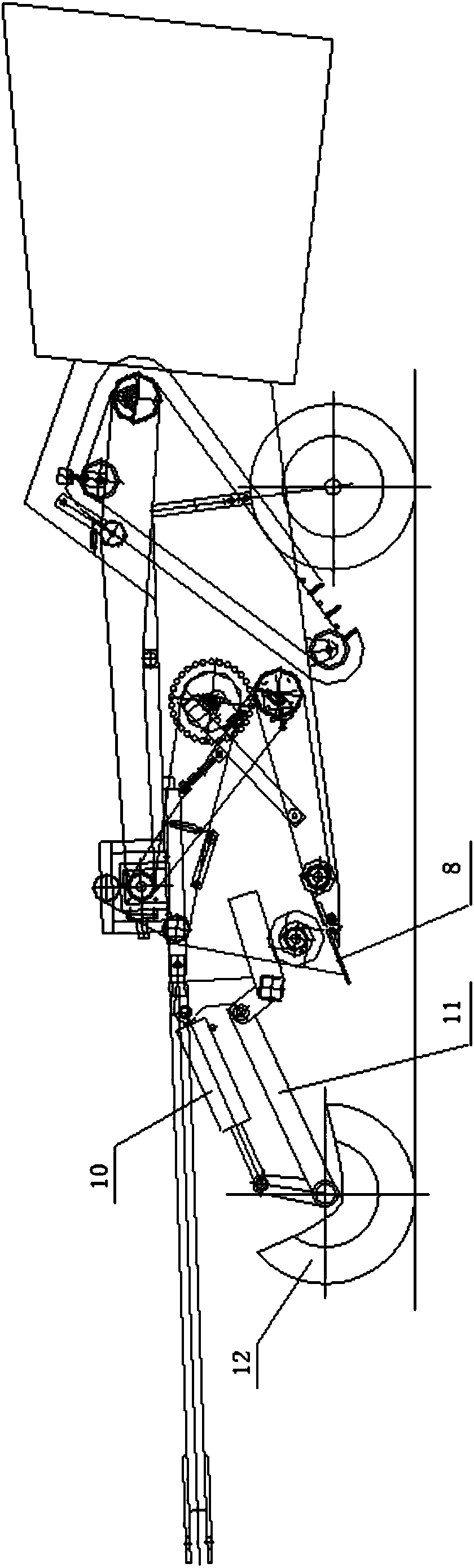

[0026] Such as Figure 1-2 As shown, the present invention discloses a farmland plow layer residual film recycling machine, comprising a frame 2, which is distinguished from the front and rear along the forward direction of the device, a traction frame 1 is arranged at the front end of the frame 2, and a traction frame 1 is arranged at the rear end bottom of the frame 2. The rear traveling wheels 7 are provided, and the frame 2 is also provided with a transmission system, a soil entry depth adjustment mechanism, a film lifting blade 8, a film soil conveying mechanism, and a film collection box 6. The transmission system is connected with an external drive mechanism, and the transmission system drives The film soil conveying mechanism, the height difference between the soil entry depth adjustment mechanism and the film lifting blade 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com