Black sesame and ginseng crisp chips and making method thereof

A technology of black sesame and black sesame powder, which is applied in the direction of food ingredients as taste improvers, functions of food ingredients, food drying, etc., can solve the problems that restrict the consumption and promotion of ginseng products, achieve good taste and appearance, enhance memory, Ease of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

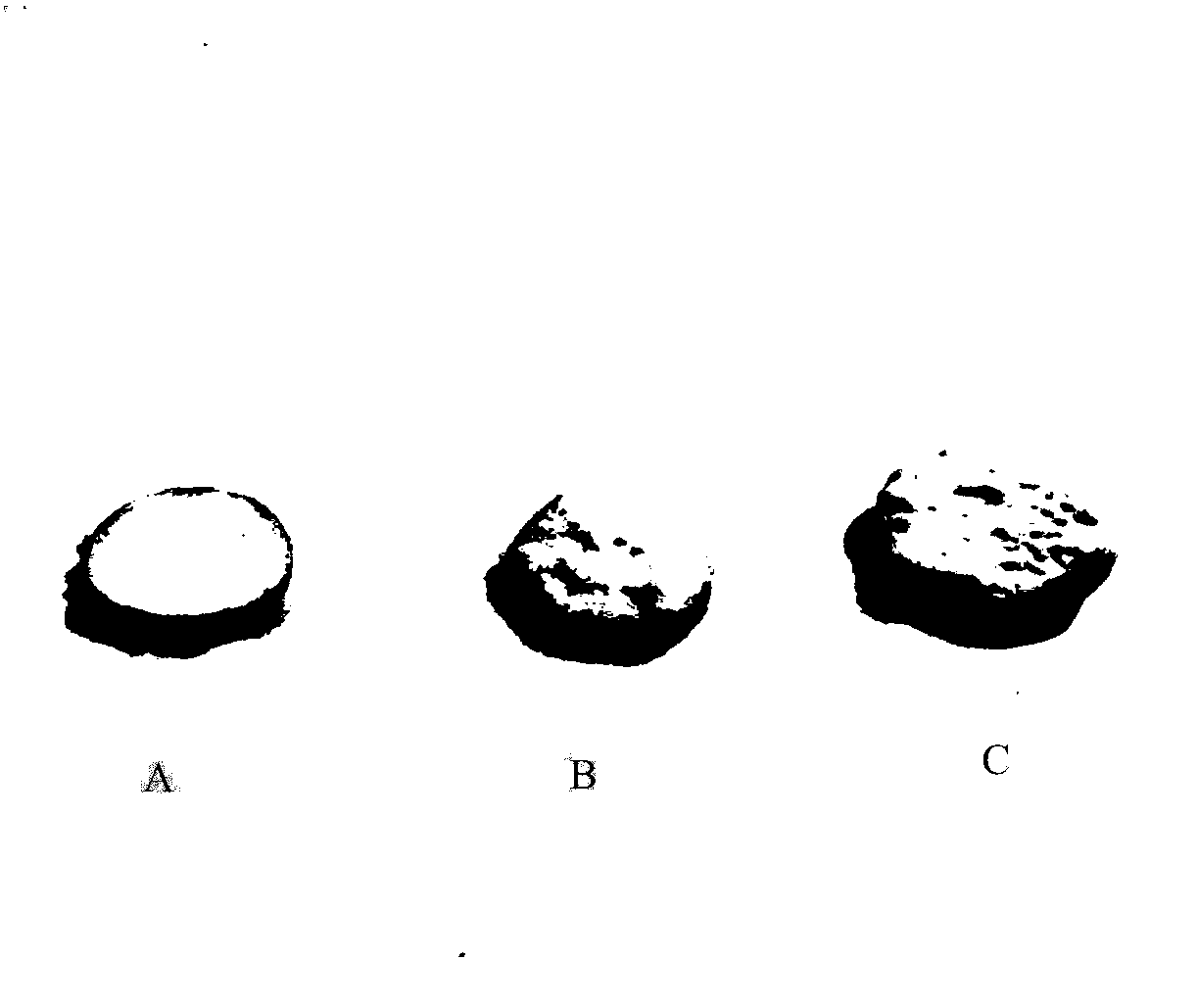

[0018] Embodiment 1. Fresh ginseng is cut into thin slices of 2 mm, and the fresh ginseng slices that have been cut are spread flatly in the preparation liquid, and the preparation liquid is made up of the following raw materials of mass fraction: black sesame powder 6%, milk powder 10%, edible Tapioca starch 12%, maltodextrin 20% and xylitol 1.5%, the rest is water. Then put it into a vacuum drying oven, under the conditions of 50°C and 0.1MPa, vacuum fill it for 45 minutes, take it out for shaping, put it in -75°C for pre-freezing for 3 hours, take it out and put it in a vacuum freeze drying oven at -45°C for 60 hours to obtain black sesame ginseng crisps, such as figure 1 As shown in A.

Embodiment 2

[0019] Embodiment 2. Fresh ginseng is cut into thin slices of 2 mm, and the fresh ginseng slices that have been cut are flatly spread in the preparation solution, and the preparation solution is composed of the following raw materials in mass fractions: black sesame powder 5%, milk powder 8%, edible Tapioca starch 10%, maltodextrin 15% and xylitol 1%, the rest is water. Then put it into a vacuum drying oven, under the conditions of 45°C and 0.1MPa, vacuum fill it for 40 minutes, take it out for shaping, put it in -80°C for pre-freezing for 2 hours, take it out and put it in a vacuum freeze drying oven at -50°C for 48 hours to obtain black sesame ginseng crisps, such as figure 1 Shown in B.

Embodiment 3

[0020] Embodiment 3. Fresh ginseng is cut into thin slices of 2 mm, and the fresh ginseng slices that have been cut are flatly spread in the preparation liquid, and the preparation liquid is made up of the following raw materials of mass fraction: black sesame powder 4%, milk powder 6%, edible Tapioca starch 8%, maltodextrin 10% and xylitol 0.5%, the rest is water. Then put it into a vacuum drying oven, under the conditions of 45°C and 0.08MPa, vacuum fill for 30 minutes, take it out for shaping, put it in -85°C for pre-freezing for 1 hour, take it out and put it in a vacuum freeze drying oven at -55°C for 24 hours to obtain black sesame ginseng crisps, such as figure 1 C shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com