Method and cutting tool for machining inclined planes of diesel engine base

A diesel engine and bevel technology, which is applied in the processing of diesel engine base size bevels and diesel engine parts, to achieve the effects of ensuring product quality, reducing processing costs, and high processing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

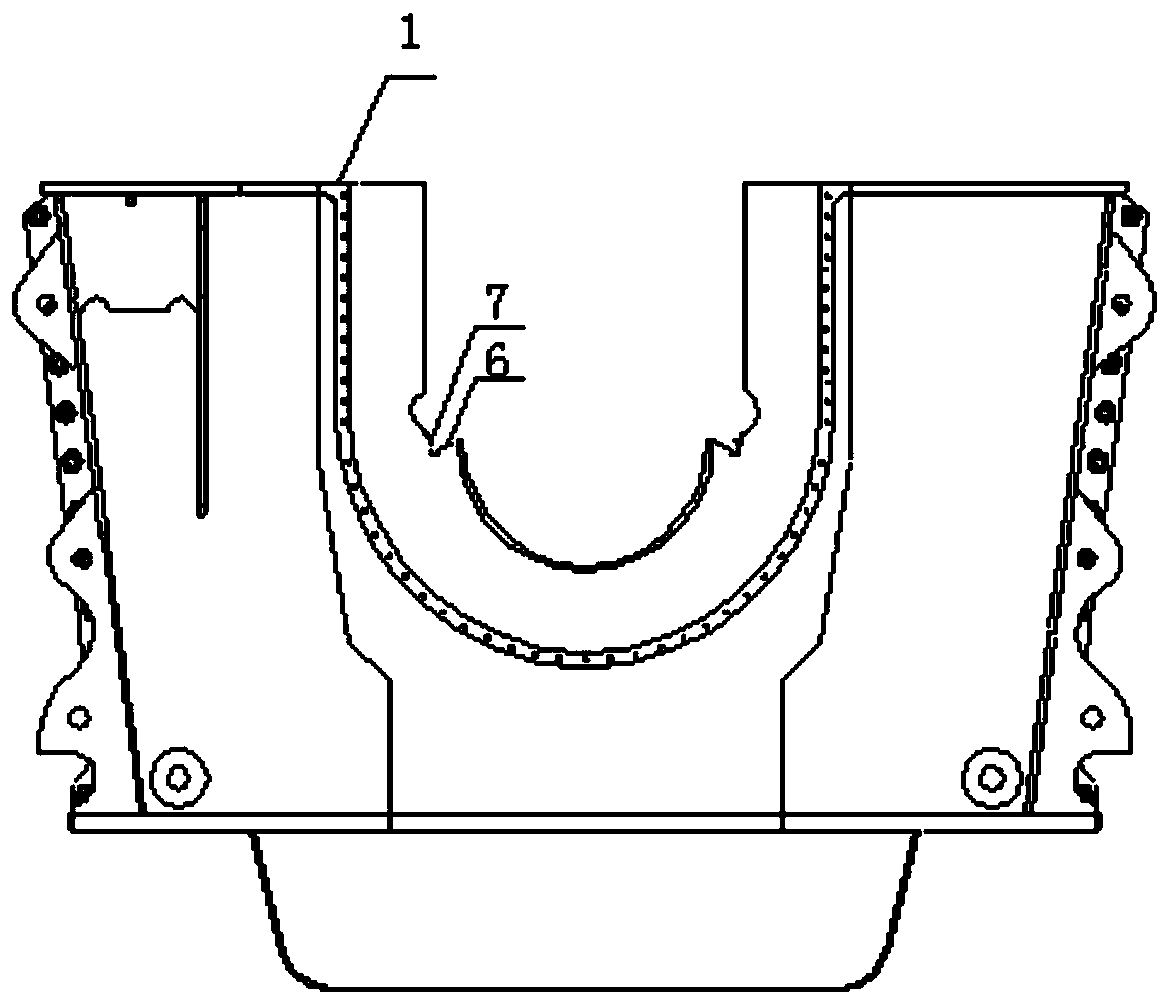

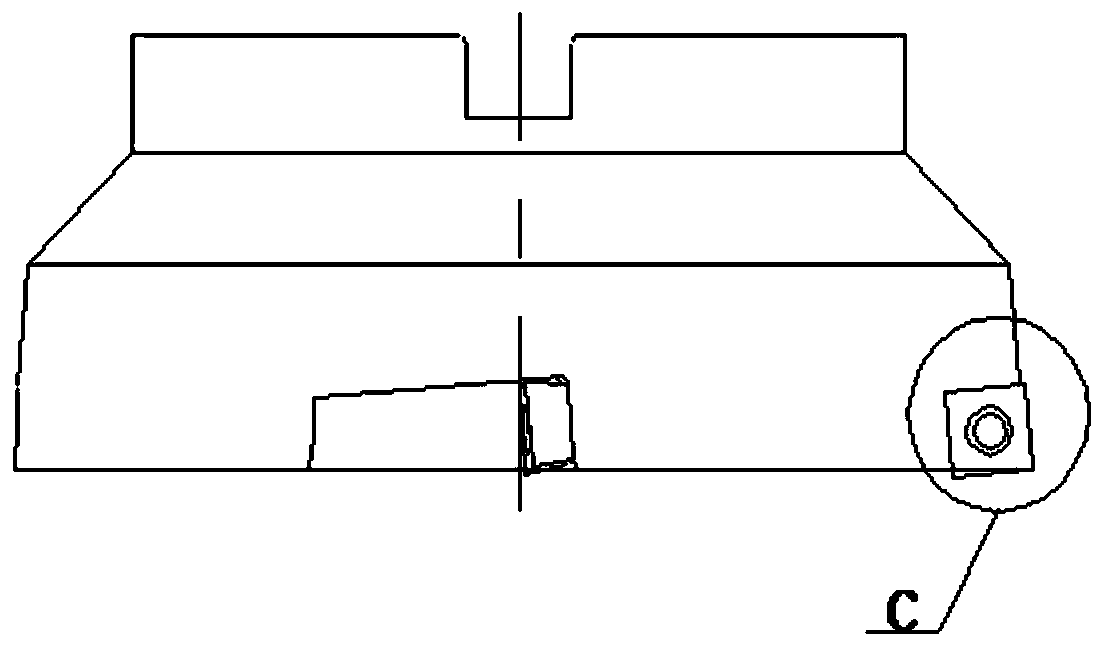

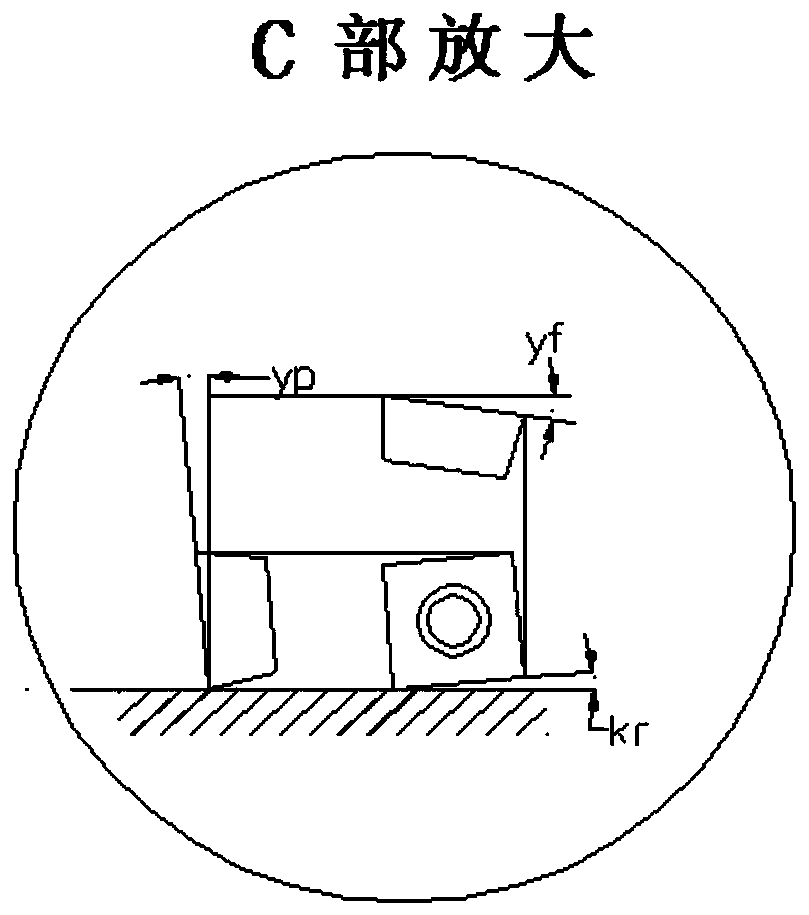

[0030] The present invention is used for the processing of the large and small inclined planes of the base, see Figure 10 , the large inclined plane 6 and the small inclined plane 7 are the mating surfaces for the installation of the inner bearing seat and the bearing cover of the machine base 1, the small inclined plane 7 is perpendicular to the large inclined plane 6, and the large inclined plane 6 forms an angle of 25° with the plane of the machine base 1; including the use of three types The special cutting tool automatically completes the plunge-milling rough machining, margin-removing rough machining and finishing process of all inclined planes on the machine base through the numerical control program instructions, which solves the problem that the traditional machining methods cannot do.

[0031] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0032] In the three major steps of processing, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com