Novel brazing diamond fine hole drill for drilling hard and brittle materials

A technology of hard and brittle materials and diamond, which is applied in the production field of superabrasive drill bits, can solve the problems of inability to process drill teeth and difficult arrangement, etc., and achieve the effects of good drilling stability, improved stability and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Design a brazed diamond drill bit that can be used for drilling hard ceramic materials and drilling blind holes. The drilling diameter is 6mm and the depth is 30mm.

[0035] In this embodiment, since the drilling is required to be a blind hole, and the hole diameter is small, the debris is not easy to discharge, and the coolant needs to be injected from the core to discharge the debris, and the drilling is required to be sharp so as not to block the core hole. The specific plan is as follows:

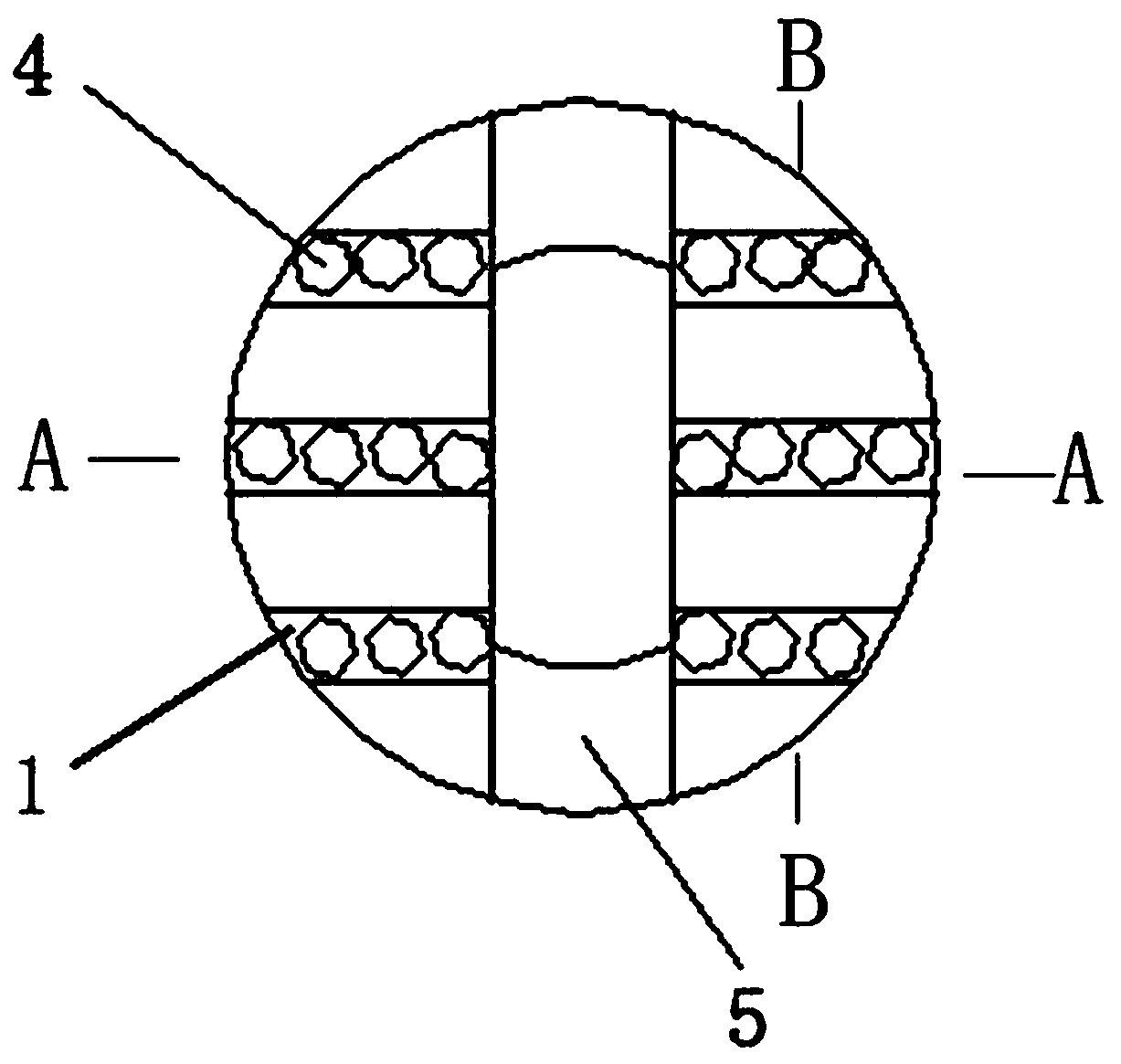

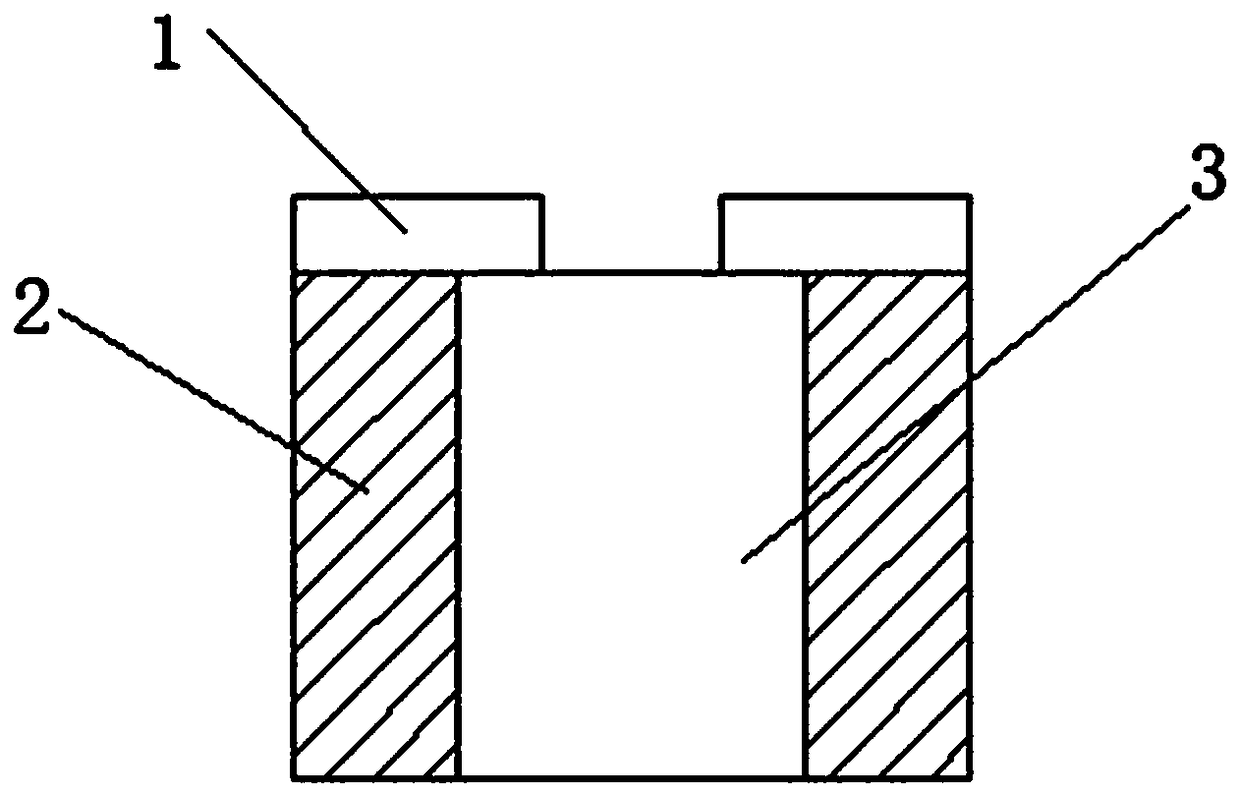

[0036] The base material is 40Cr steel, the average particle size of the diamonds arranged at the upper end is 0.35 mm, the outer diameter of the base is 5.2 mm, the size of the inner hole 3 is 2.8 mm, the wall thickness of the drilling shank 2 is 1.2 mm, and the width of the top wide groove 5 is 5 mm. The depth of the wide groove is 2mm; the number of thin grooves 1 on the top of the drill bit is determined to be 3 according to the aforementioned formula, and the depth of the th...

Embodiment 2

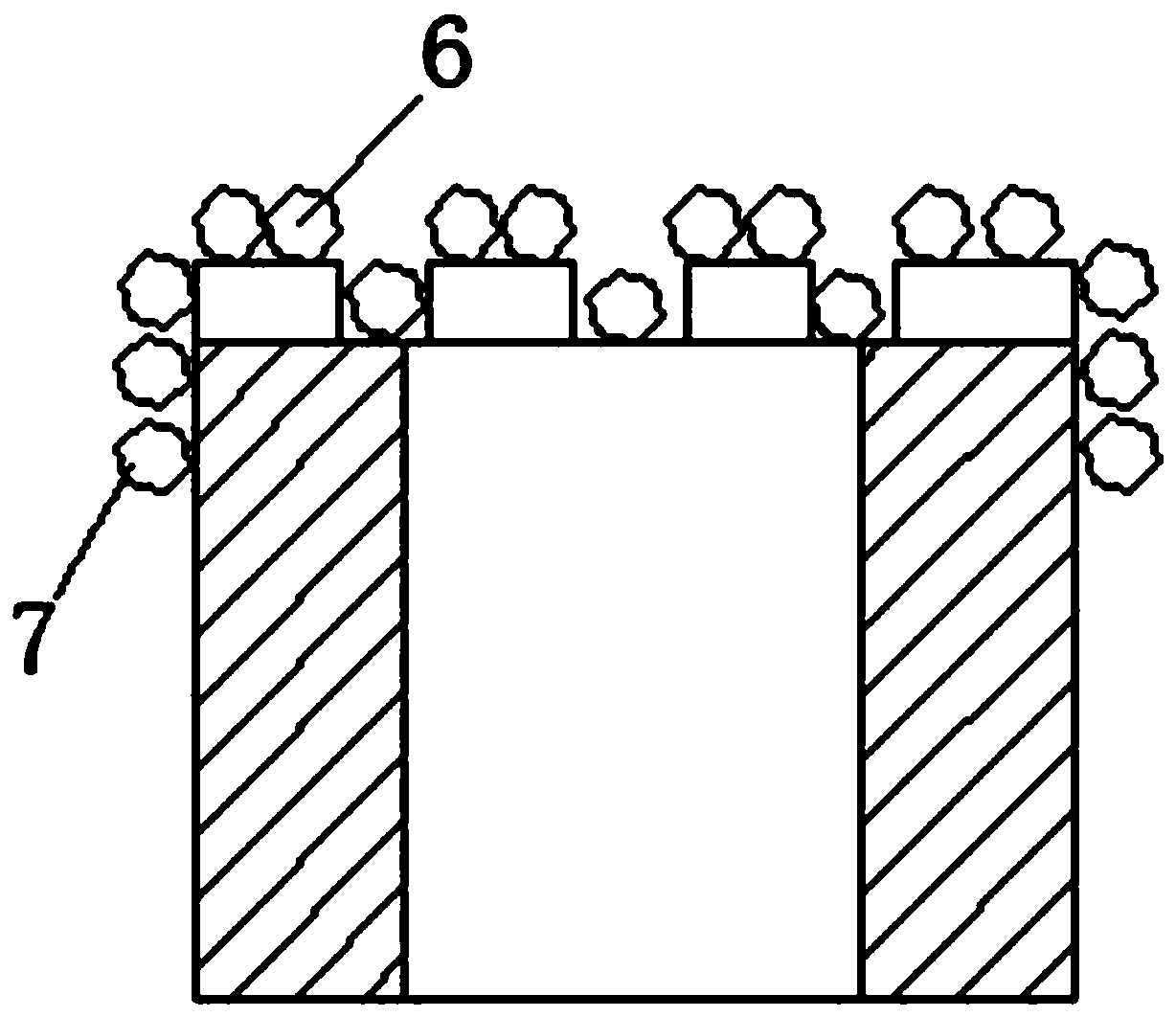

[0042] In this embodiment, a wide groove 5 is arranged on the top of the drilling head, the width is equal to 1 / 3 of the diameter of the inner hole 3, and the depth is 1 mm. The diamond abrasive grains are embedded in the fine groove 1, that is, the top fine groove diamond 4, and the diamond abrasive grains are arranged on the rest of the top of the drilling head and the top side wall, which are respectively the top diamond 6 and the side diamond 7, and the side wall is arranged The cloth width is 3mm~12mm; the height of the diamond abrasive grains embedded in the fine grooves is 1.0~1.3 times the depth of the fine grooves, and the width of the fine grooves is 1.3~1.6 times the diameter of the diamond abrasive grains

[0043] The matrix material is steel, the diamond particle size arranged at the upper end is 0.15mm, the outer diameter of the matrix is 3mm, the wall thickness of the drilling shank 2 is 0.8mm, the width of the top wide groove 5 is 1mm, and the groove depth is ...

Embodiment 3

[0045] In this embodiment, a wide groove 5 is arranged on the top of the drilling head, the width is equal to 1 / 4 of the diameter of the inner hole 3, and the depth is 1 mm. The diamond abrasive grains are embedded in the fine groove 1, that is, the top fine groove diamond 4, and the diamond abrasive grains are arranged on the rest of the top of the drilling head and the top side wall, which are respectively the top diamond 6 and the side diamond 7, and the side wall is arranged The cloth width is 3mm~12mm; the height of the diamond abrasive grains embedded in the fine grooves is 1.0~1.3 times the depth of the fine grooves, and the width of the fine grooves is 1.3~1.6 times the diameter of the diamond abrasive grains

[0046] The matrix material is steel, the diamond grain size arranged at the upper end is 0.5mm, the outer diameter of the matrix is 1.2mm, the wall thickness of the drilling shank 2 is 0.9mm, the top wide groove 5 has a width of 1mm, and a groove depth of 1mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com