Automotive exterior trim material capable of being directly coated by water-based paint and preparation method of exterior trim material

A water-based paint and automotive technology, applied in the field of materials, can solve the problems of ineffective improvement of the polarity of polypropylene materials, complicated paint spraying process, and degradation of material performance, and achieve high strength, shortened injection molding cycle, and low shrinkage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with embodiment the present invention is described in further detail.

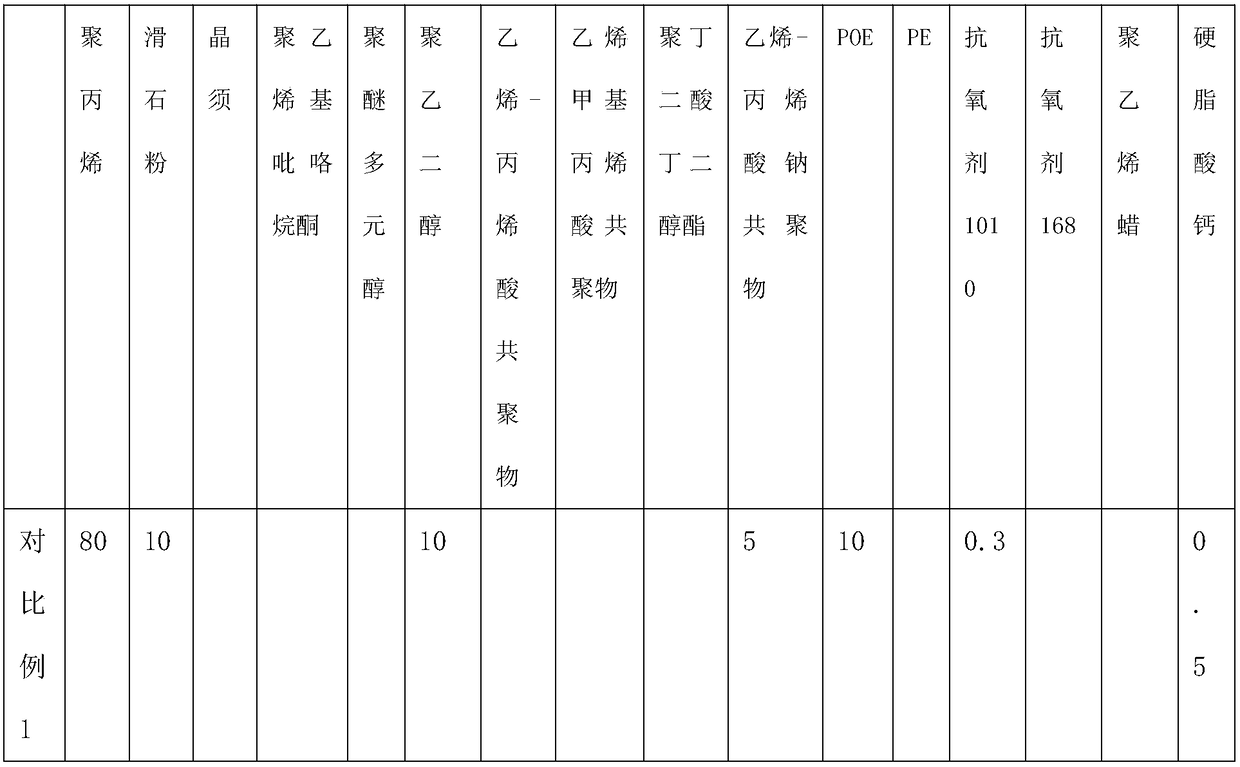

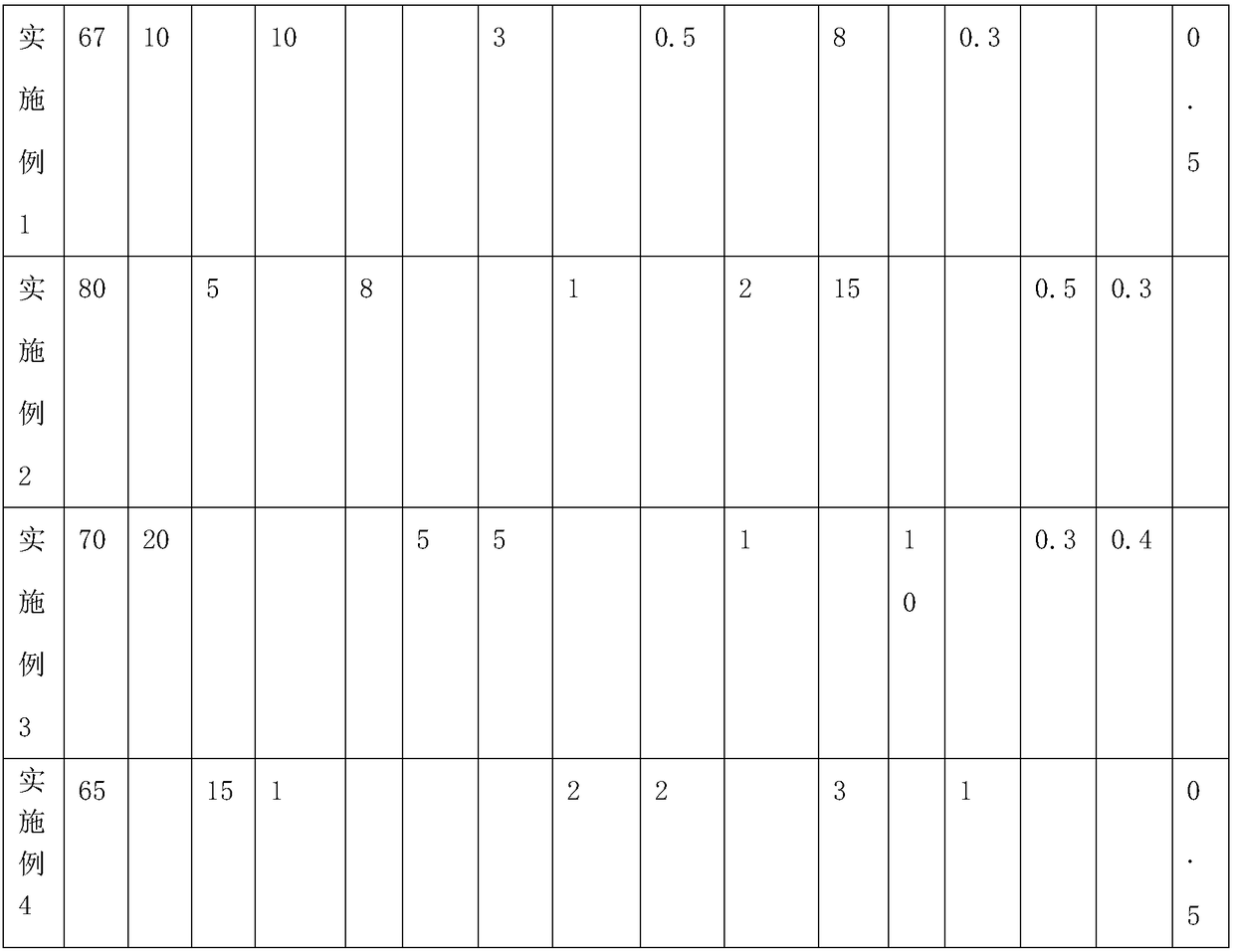

[0030] According to the specific formula of the following table according to the above-mentioned preparation method, obtain comparative example 1, embodiment 1, embodiment 2, embodiment 3, embodiment 4, wherein, the polypropylene melt index in comparative example 1 is 30g / 10min, in embodiment 1 The polypropylene melt index is 30g / 10min, and the polypropylene melt index is 40g / 10min among the embodiment 2, and the polypropylene melt index is 60g / 10min among the embodiment 3, and the polypropylene melt index is 100g / 10min among the embodiment 4, concrete formula As shown in the table below.

[0031]

[0032]

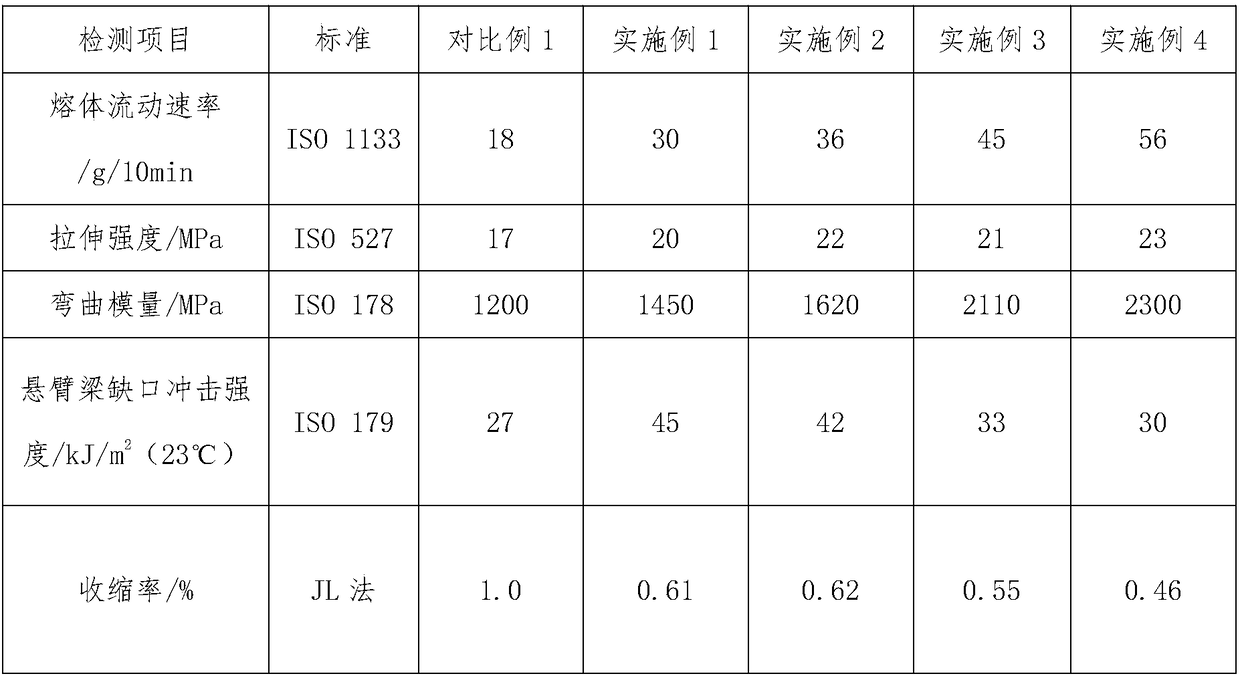

[0033] Product comparative example and embodiment performance table of the present invention

[0034]

[0035]

[0036] From the above table, it can be seen that compared with Comparative Example 1, the polypropylene material of the present invention has a lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com