Preparation method of high-solid-content epoxy composite material for badminton racket

A technology for badminton rackets with high solid content, applied to rackets, string-through rackets, sports accessories, etc., can solve the problems of improving the flexibility of epoxy compositions, and achieve the effect of improving flexibility and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

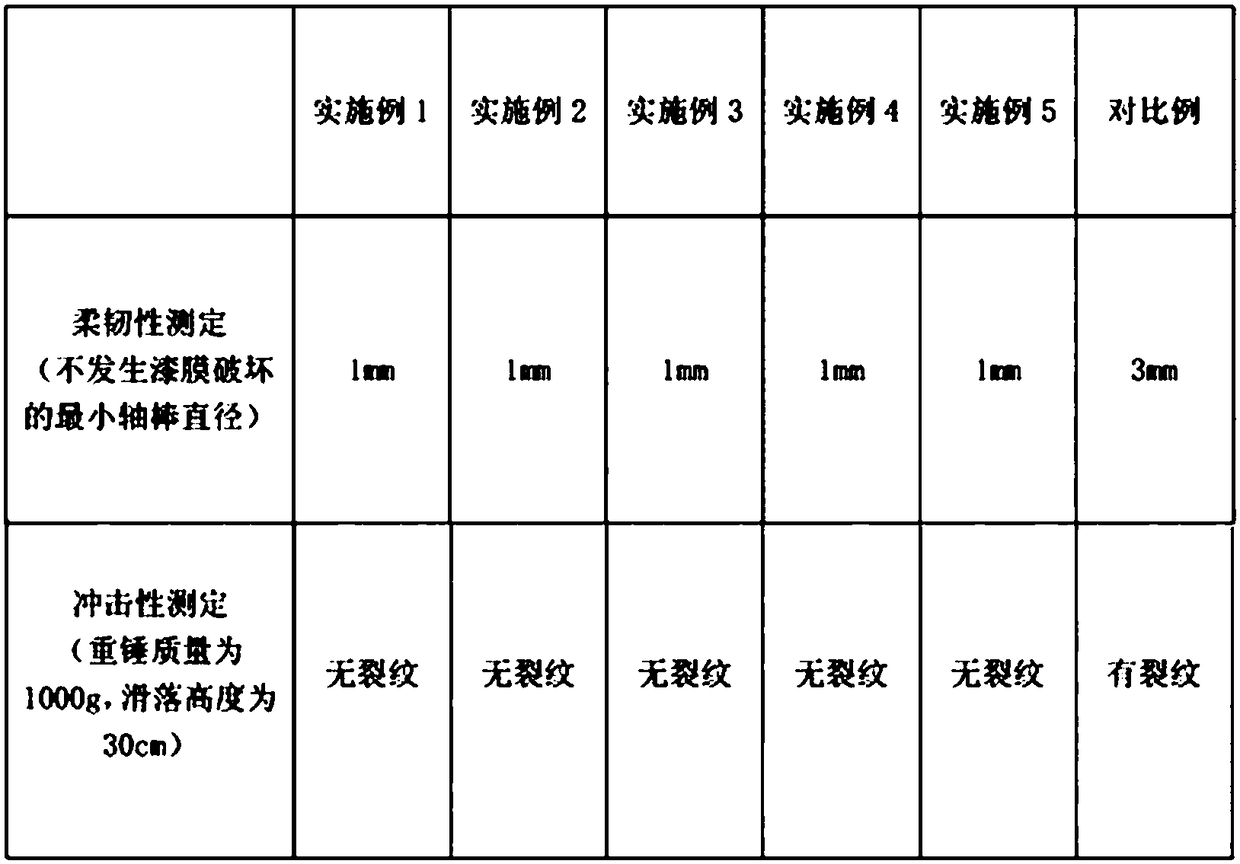

Examples

Embodiment 1

[0029] A kind of high-solid-content epoxy composite material for badminton racket, in parts by weight, comprises the following components

[0030] 73 parts of epoxy resin, 23 parts of butyl methacrylate,

[0031] 7 parts of nano titanium sol, 2.5 parts of curing agent,

[0032] 2.5 parts of amino polyether, 3.5 parts of carboxylated styrene-butadiene rubber,

[0033] 1.5 parts of antirust agent, 2.5 parts of dispersant, 2.5 parts of leveling agent.

[0034] Its preparation method comprises the following steps:

[0035] (1) Add epoxy resin to xylene, heat to 85°C, stir under the protection of nitrogen, add free radical initiator (benzoyl peroxide), drop butyl methacrylate monomer, drop Stop stirring after finishing, and continue to insulate for 4h, after cooling to room temperature, obtain mixed solution A, be the epoxy resin solution of butyl methacrylate modification,

[0036] (2) Add carboxylated styrene-butadiene rubber, amino polyether, and dispersant to mixed solution...

Embodiment 2

[0040] A kind of high-solid-content epoxy composite material for badminton racket, in parts by weight, comprises the following components

[0041] 78 parts of epoxy resin, 24 parts of butyl methacrylate,

[0042] 7.5 parts of nano titanium sol, 2.7 parts of curing agent,

[0043] 4.3 parts of amino polyether, 4.0 parts of carboxylated styrene-butadiene rubber,

[0044] 1.5 parts of antirust agent, 2.8 parts of dispersant, 2.7 parts of leveling agent.

[0045] Its preparation method comprises the following steps

[0046] (1) Add epoxy resin to xylene, heat to 90°C, stir under the protection of nitrogen, add free radical initiator (benzoyl peroxide), drop butyl methacrylate monomer, drop Stop stirring after finishing, and continue to insulate for 4h, after cooling to room temperature, obtain mixed solution A, be the epoxy resin solution of butyl methacrylate modification;

[0047] (2) Add carboxylated styrene-butadiene rubber, amino polyether, and dispersant to mixed solutio...

Embodiment 3

[0051] A kind of high-solid-content epoxy composite material for badminton racket, in parts by weight, comprises the following components

[0052] 82 parts of epoxy resin, 25 parts of butyl methacrylate,

[0053] 8 parts of nano titanium sol, 2 parts of curing agent,

[0054] 4 parts of amino polyether, 3.7 parts of carboxylated styrene-butadiene rubber,

[0055] 2.3 parts of antirust agent, 3.5 parts of dispersant, 3.2 parts of leveling agent.

[0056] Its preparation method comprises the following steps

[0057](1) Add epoxy resin to xylene, heat to 95°C, stir under the protection of nitrogen, add free radical initiator (benzoyl peroxide), drop butyl methacrylate monomer, drop Stop stirring after finishing, and continue to insulate for 4h, after cooling to room temperature, obtain mixed solution A, be the epoxy resin solution of butyl methacrylate modification;

[0058] (2) Add carboxylated styrene-butadiene rubber, amino polyether, and dispersant to mixed solution A and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com