A kind of sugar juice compound decolorizing agent and the method for sugar juice decolorization

A compound reagent and sugar juice technology, which is applied in the field of sugar juice compound decolorizer and sugar juice decolorization, can solve the problems of process lengthening, sucrose loss and color value increase, and achieve high product quality, reduce color value and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

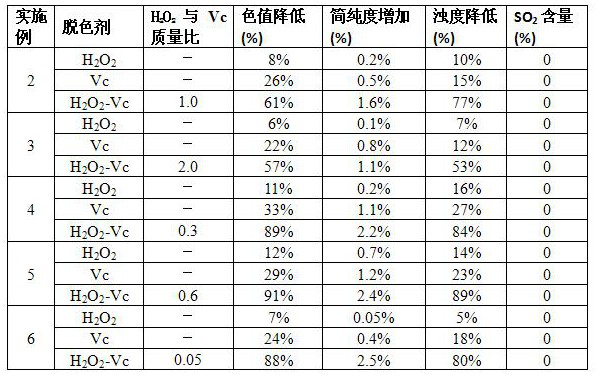

Examples

Embodiment 1

[0024] Embodiment 1: a kind of sugar juice compound decolorizing agent, this sugar juice compound decolorizing agent is made of H 2 o 2 H with vitamin C 2 o 2 -Vc complex reagent, H 2 o 2 The mass ratio to vitamin C is 0.01-10, preferably 0.3-1.0, more preferably 0.6.

Embodiment 2

[0025] Embodiment 2: a kind of method for sugar juice decolorization, adopt the H described in embodiment 1 2 o 2 -Vc compound reagent carries out decolorization treatment to sugar juice, and described sugar juice is mixed juice, adopts H 2 o 2 -Vc composite reagent decolorizes the mixed juice, during the decolorization process, H 2 o 2 -The mass ratio of the addition amount of Vc composite reagent to the mixed juice is 10×10 -6 ~2×10 -3 , about to H 2 o 2 -Vc compound reagent is added to the mixed juice from the press, before sulfur fumigation and neutralization, the mixed juice is mixed with H during the flow and pumping process, or in the buffer storage tank 2 o 2 The -Vc complex reagent is fully mixed and reacted to achieve the purpose of decolorization.

Embodiment 3

[0026] Embodiment 3: a kind of method for juice decolorization, adopt the H described in embodiment 1 2 o 2 -Vc compound reagent carries out decolorization treatment to sugar juice, and described sugar juice is clear juice, adopts H 2 o 2 -Vc compound reagent decolorizes the clear juice, during the decolorization process, H 2 o 2 -The mass ratio of the addition amount of Vc composite reagent to the clear juice is 10×10 -6 ~2×10 -3 , about to H 2 o 2 -Vc compound reagent is added to the clear juice, and the clear juice will be mixed with H in the process of flowing and pumping, or in the buffer storage tank 2 o 2 The -Vc complex reagent is fully mixed and reacted to achieve the purpose of decolorization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com