Density-distributed micro-chromatographic column chip and its manufacturing method

A technology of density distribution and manufacturing method, applied in the field of chromatographic analysis, can solve the problems of unfavorable, poor anti-interference ability, low resolution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

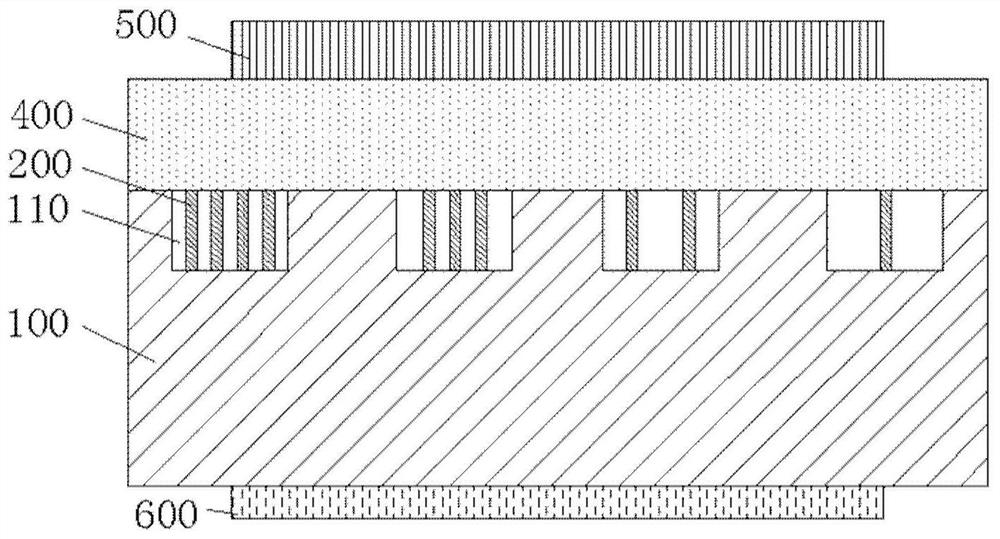

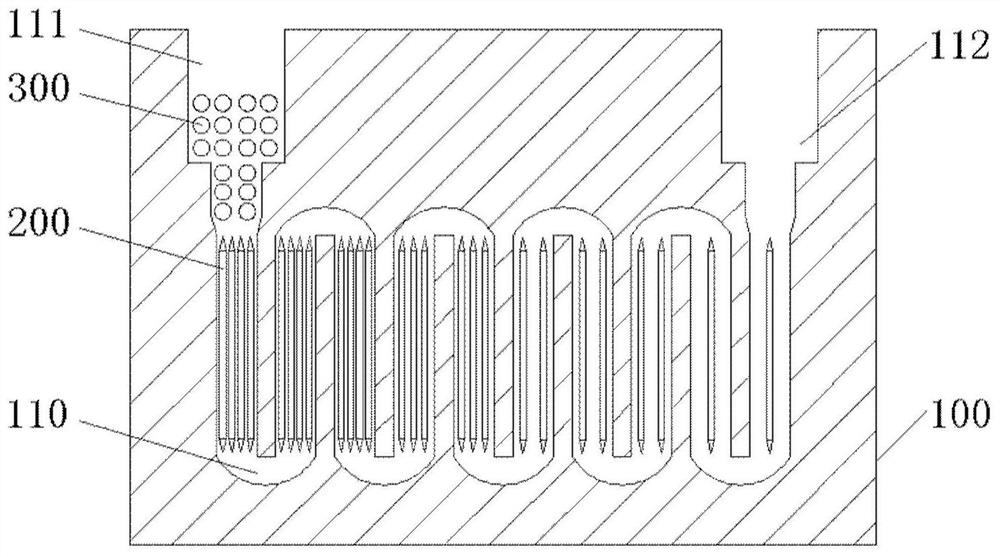

[0026] The present disclosure provides a density-distributed micro-chromatographic column chip and a manufacturing method thereof. Since the air resistance in the channel close to the inlet part is small, the closer to the outlet of the chromatographic column, the greater the gas resistance, and the flow rate of gas in the entire chromatographic channel and the pressure distribution is very uneven, so the disclosure improves the surface area and sample capacity of the chromatographic channel by changing the setting density of the column wall in the channel, and optimizes the flow velocity and pressure distribution in the chromatographic channel to make them tend to be consistent. It is conducive to the uniform coating of the stationary phase in the chromatographic channel, so as to realize the efficient separation of samples.

[0027] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further descri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com