Sealed continuous slag discharging device for boiling chlorination production of titanium tetrachloride gravity dust collector

A technology of titanium tetrachloride and boiling chlorination, which is applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve the problem that the leakage of chlorine-containing waste gas has not been well treated, and the establishment of energy-saving and emission-reduction problems in enterprises , Immediately use a large amount of alkaline water or clean water to achieve the effect of improving continuous operation ability, eliminating scald accidents, and improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

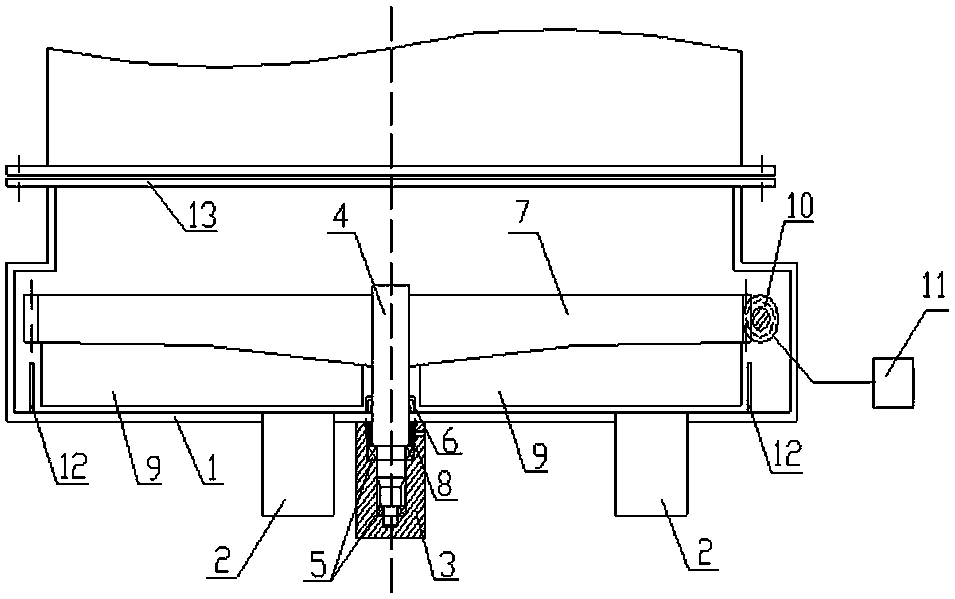

[0024] Such as figure 1 As shown, a closed slag discharge device using a gravity dust collector in the production of titanium tetrachloride by the boiling chlorination method is mainly composed of a device shell 1, a slag discharge pipe 2, a shaft sleeve 3, a shaft 4, a bearing 5, and a protective ring Ring 6, hollow turbine 7, gland 8, scraper 9 for collecting dust, worm rod 10, driving device 11, ring 12 for retaining slag, and flange 13. The top of the shell 1 is provided with the flange 13 and the bottom of the dust collector. Connection, the slag discharge pipe 2 is welded under the bottom plate of the shell 1, the slag retaining ring 12 is welded in the bottom plate of the device shell 1, the shaft sleeve 3 is welded at the center of the bottom plate of the shell 1, the shaft 4, the gland 8 and the bearing 5 are connected to each other Cooperate and set in the shaft sleeve 3, the protective ring 6 is welded on the connection between the shaft 4 and the bottom plate of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com