Three-dimensional porous nitrogen-doped graphene composite material and preparation method of nitrogen-doped graphene

A nitrogen-doped graphene, three-dimensional porous technology, applied in graphene, chemical instruments and methods, nanotechnology for materials and surface science, etc., to achieve the effect of low cost and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

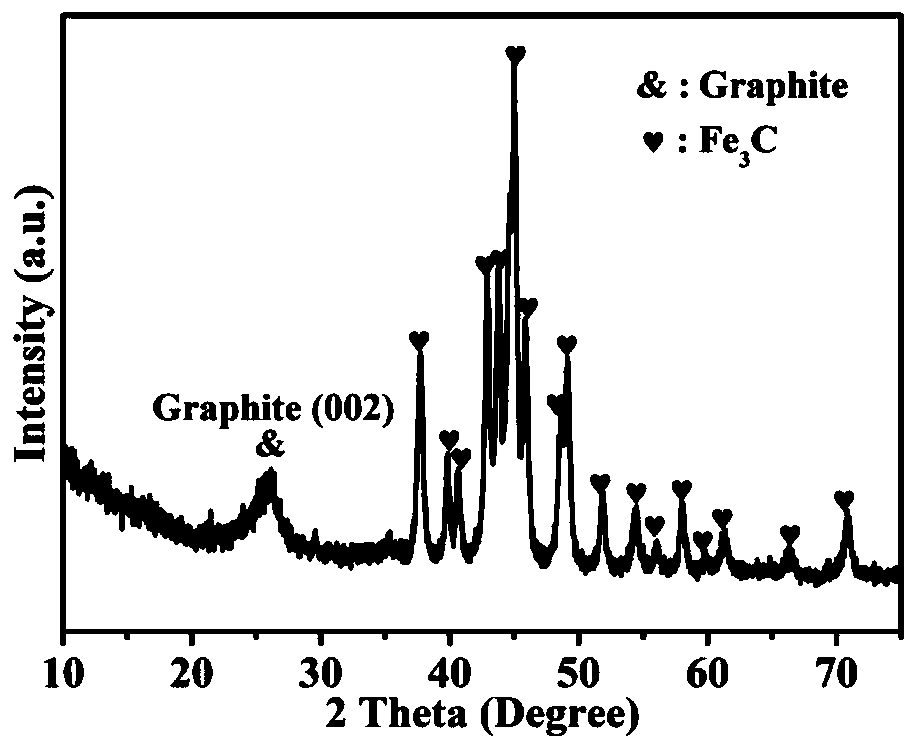

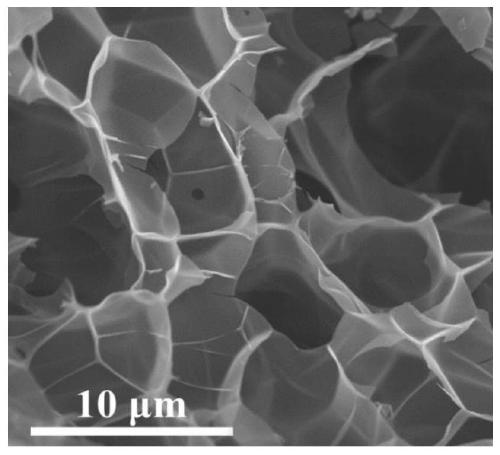

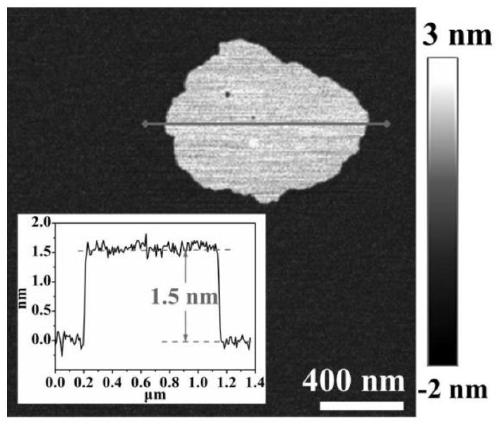

[0029] Weigh polyvinylpyrrolidone powder and ferric nitrate nonahydrate according to the mass ratio of 1:1, dissolve ferric nitrate nonahydrate and polyvinylpyrrolidone nonahydrate respectively in deionized water to make a mixed solution and ultrasonically stir for 10 minutes, then place the mixed solution in air-dried Keep warm at 80°C in the box until it is completely dry, then grind the dried product into powder and transfer the powder to a crucible, which is placed in a tube furnace under N 2 Heated to 700°C at a heating rate of 5°C / min in the atmosphere, and held for 1 hour. After the tube furnace cooled, the black foamy product was collected to obtain a three-dimensional porous nitrogen-doped graphene composite material decorated with iron carbide nanoparticles.

Embodiment 2

[0031] Weigh polyvinylpyrrolidone powder and ferric nitrate nonahydrate according to the mass ratio of 1:1.5, dissolve ferric nitrate nonahydrate and polyvinylpyrrolidone nonahydrate respectively in deionized water to make a mixed solution and stir it ultrasonically for 10 minutes, then place the mixed solution in air-dried Keep warm at 80°C in the box until it is completely dry, then grind the dried product into powder and transfer the powder to a crucible, which is placed in a tube furnace under N 2 Heated to 700°C at a heating rate of 5°C / min in the atmosphere, and held for 1 hour. After the tube furnace cooled, the black foamy product was collected to obtain a three-dimensional porous nitrogen-doped graphene composite material decorated with iron carbide nanoparticles.

Embodiment 3

[0033] Weigh polyvinylpyrrolidone powder and ferric nitrate nonahydrate according to the mass ratio of 1:2.0, dissolve ferric nitrate nonahydrate and polyvinylpyrrolidone nonahydrate respectively in deionized water to form a mixed solution and stir it ultrasonically for 10 minutes, then place the mixed solution in air-dried Keep warm at 80°C in the box until it is completely dry, then grind the dried product into powder and transfer the powder to a crucible, which is placed in a tube furnace under N 2 Heated to 700°C at a heating rate of 5°C / min in the atmosphere, and held for 1 hour. After the tube furnace cooled, the black foamy product was collected to obtain a three-dimensional porous nitrogen-doped graphene composite material decorated with iron carbide nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com