UV-postcured modified aqueous polycarbonate polyurethane emulsion and preparation method thereof

A technology of polyurethane emulsion and polycarbonate, which is applied in the field of coatings and can solve the problems of high cost and high cost of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in conjunction with Embodiment 1~5:

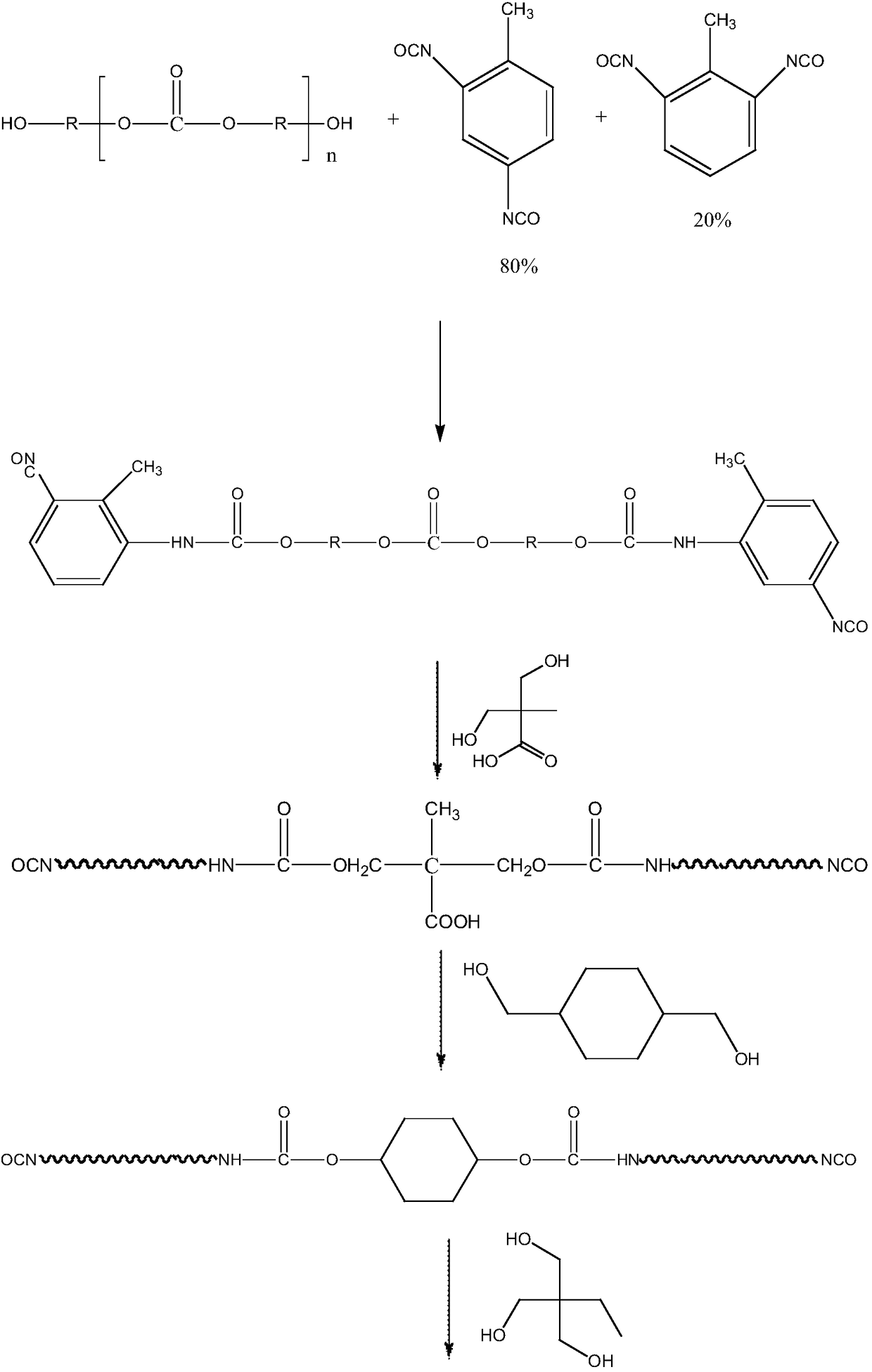

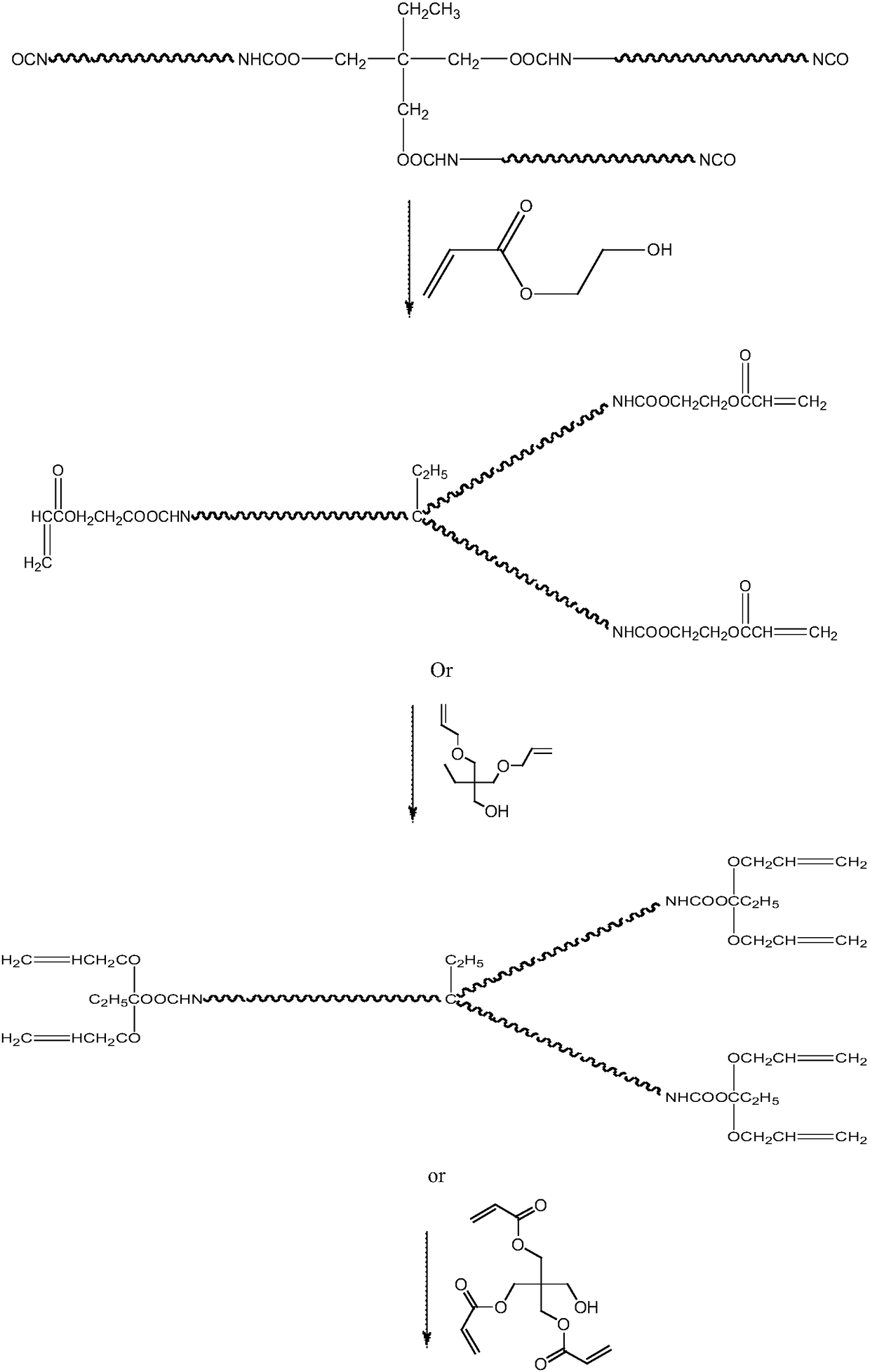

[0028] A kind of preparation method of UV post-curing modified aqueous polycarbonate polyurethane emulsion, comprises the steps:

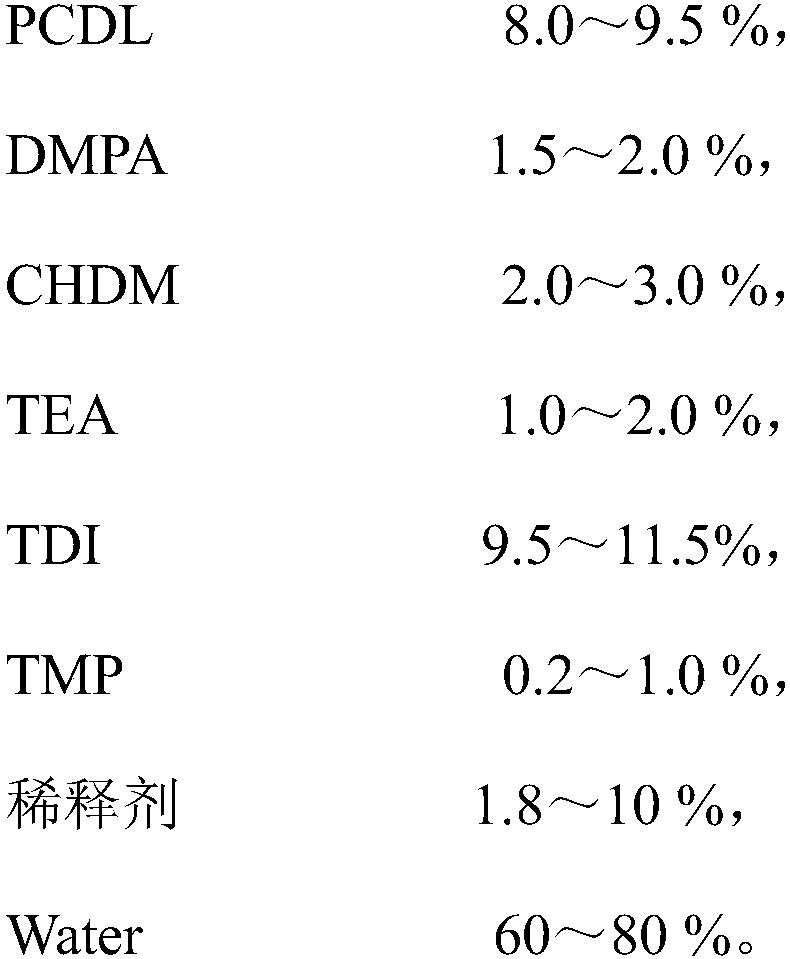

[0029] 1) Add the formulated amount of PCDL into a dry four-neck flask equipped with a stirrer, condenser and thermometer. After the temperature rises to 60°C, slowly add the formulated amount of TDI, continue to stir and heat up to 80°C for 2 hours, then cool down to 60°C and add After DMPA and TMP, heat up to 75°C to react for 1 hour, cool down to 60°C, add CHDM, 4 drops of stannous octoate catalyst, adjust viscosity with acetone, keep warm for reaction, wait until the NCO content reaches 4.81%, add the formula amount of acrylic acid hydroxyl Ethyl ester capping reaction for 2h, cooling to room temperature and adding acetone to reduce viscosity;

[0030] 2) Transfer the obtained prepolymer to an emulsification tank, add TEA to neutralize for 5 minutes un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com