Electrolytic bath of pypocholoride generator

A hypochlorite and electrolytic cell technology, applied in the field of electrolysis, can solve the problems of decreased electrolysis efficiency, low power conversion efficiency, slow solution mass transfer speed, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

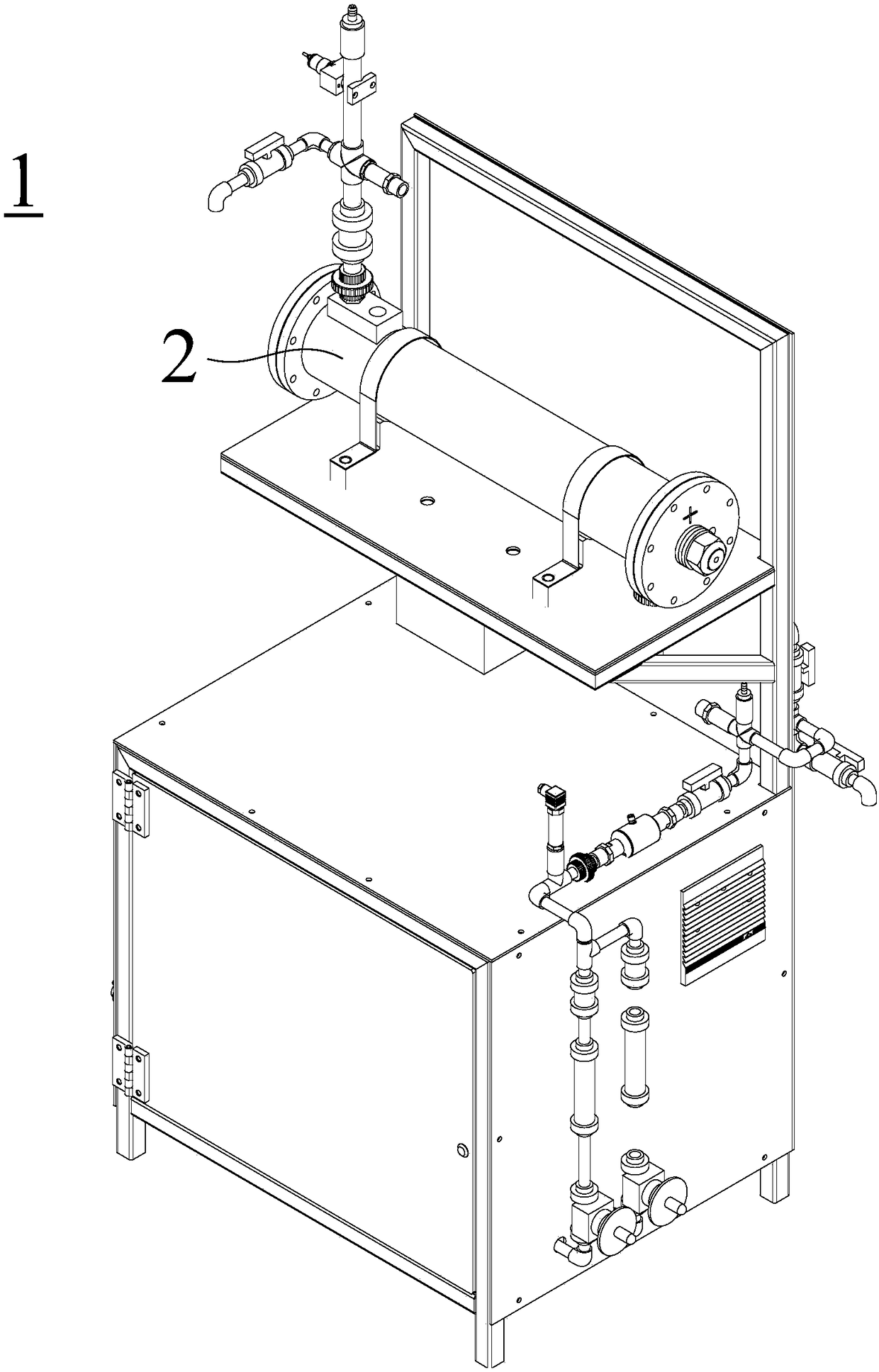

[0040] refer to Figure 1 to Figure 16 , the present embodiment provides a composite electrode assembly, the composite electrode assembly can be a composite electrode assembly of a hypochlorite generator, more specifically, the composite electrode assembly can be a composite electrode assembly of a sodium hypochlorite generator 1, the composite The electrode assembly is applied to the sodium hypochlorite generator 1 as an example to describe the structure of the composite electrode assembly.

[0041] The composite electrode assembly includes a fixing mechanism and at least one composite electrode group 20. The composite electrode assembly fixes the anode plate 21, the cathode plate 22 and the intermediate electrode plate 23 of the composite electrode group 20 by using the fixing mechanism, so that the anode plate 21, the cathode The spacing between the plate 22 and the middle plate 23 remains stable, which overcomes the defects of uneven electrode spacing and increased heat ge...

Embodiment 2

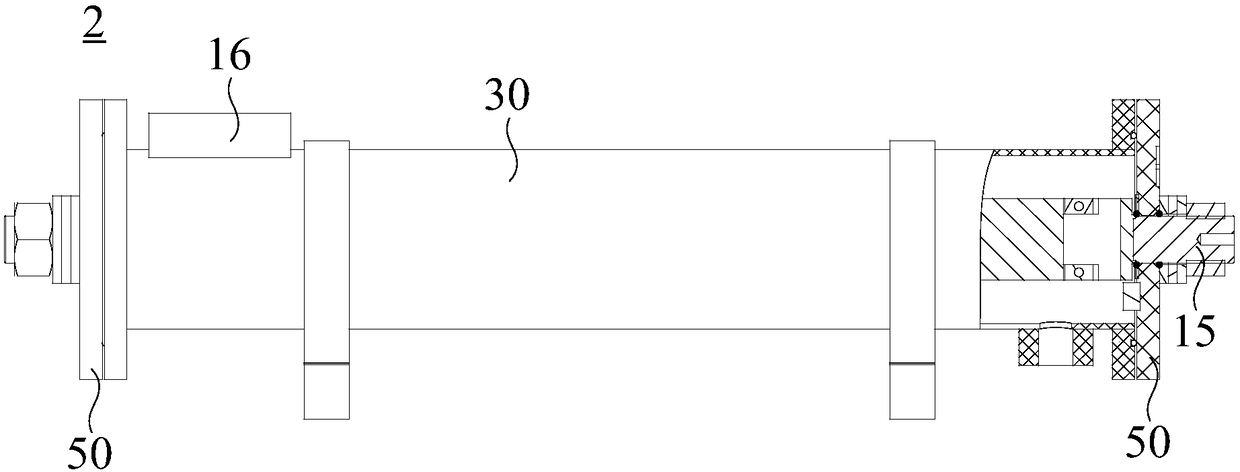

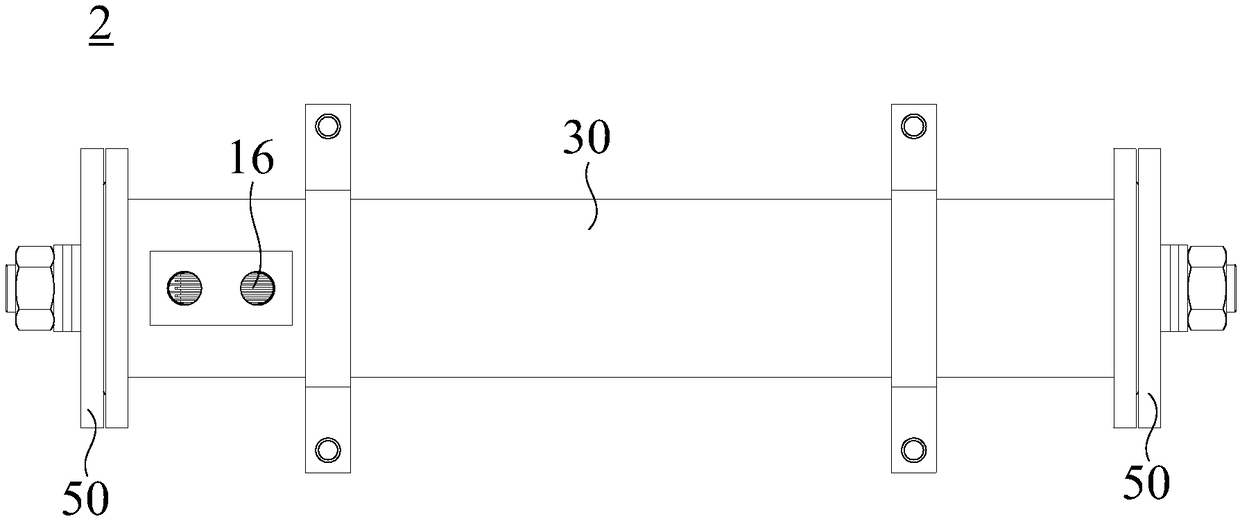

[0056] refer to Figure 2 to Figure 5 , Figure 14 , Figure 15 , the present embodiment provides an electrolytic cell 2 of a hypochlorite generator, the electrolytic cell 2 may be an electrolytic cell applied to the sodium hypochlorite generator 1, and the application of the electrolytic cell 2 to the sodium hypochlorite generator 1 is taken as an example below for this The structure of the electrolytic cell 2 of the embodiment will be described. The electrolytic cell 2 includes a casing 30, an electrode assembly, a plurality of water baffles 40, and two seals 50. The electrolytic cell 2 has a small mass transfer distance, high electrolysis efficiency, reduced calorific value, and reduced operating energy consumption.

[0057] Specifically, the electrode assembly is located in the casing 30, and the casing 30 acts as an electrolytic container. In this embodiment, the casing 30 is in the shape of a transparent cylinder and can be made of acrylic material. The liquid outlet 1...

Embodiment 3

[0063] refer to figure 1 , present embodiment provides a kind of hypochlorite generator, and this hypochlorite generator comprises electrolyzer 2, power supply (not shown) and brine pump (not shown), and this hypochlorite generator has electrolysis For the advantage of high efficiency, the structure of the hypochlorite generator in this embodiment will be described below by taking the hypochlorite generator as the sodium hypochlorite generator 1 as an example.

[0064] Specifically, the electrolytic cell 2 includes a composite electrode assembly, and the composite electrode assembly includes an anode plate 21 , a cathode plate 22 , and an intermediate electrode plate 23 located between the anode plate 21 and the cathode plate 22 . The positive pole of the power supply is connected to the anode plate 21 of the electrode assembly, and the negative pole of the power supply is connected to the cathode plate 22 of the electrode assembly. The electrolytic power supply adopts a high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com