Method and mechanism for scrubbing to remove residues from dishwasher

A dishwasher and waste residue technology, which is applied in the washing machine/washing machine of tableware, the parts of tableware washing machine/rinsing and washing machine, cleaning equipment, etc., can solve the problems of reducing the processing speed of waste residue, increasing kinetic energy consumption, and low efficiency. , to achieve the effect of reducing manufacturing difficulty, low maintenance cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: A method for rubbing and removing slag in a dishwasher according to the present invention: two crushing members are arranged in the slag removal part of the dishwasher, the two crushing members have opposite surfaces, and there is a gap between the two opposite surfaces for water to pass through ; The two opposite surfaces rotate relative to each other, and the axis of rotation intersects or is perpendicular to the plane where the two opposite surfaces are located; when removing the slag from the dishwasher, the flowing water is introduced into the gap between the two opposite surfaces, and during the relative rotation, by The two opposite surfaces knead and roll the waste slag flowing in with the water body.

[0027] The two opposite surfaces are horizontally placed one above the other, and the relative rotation axes are vertically arranged; the upper crushing member is provided with water body and waste slag inlet channel, and the lower crushing member is...

Embodiment 2

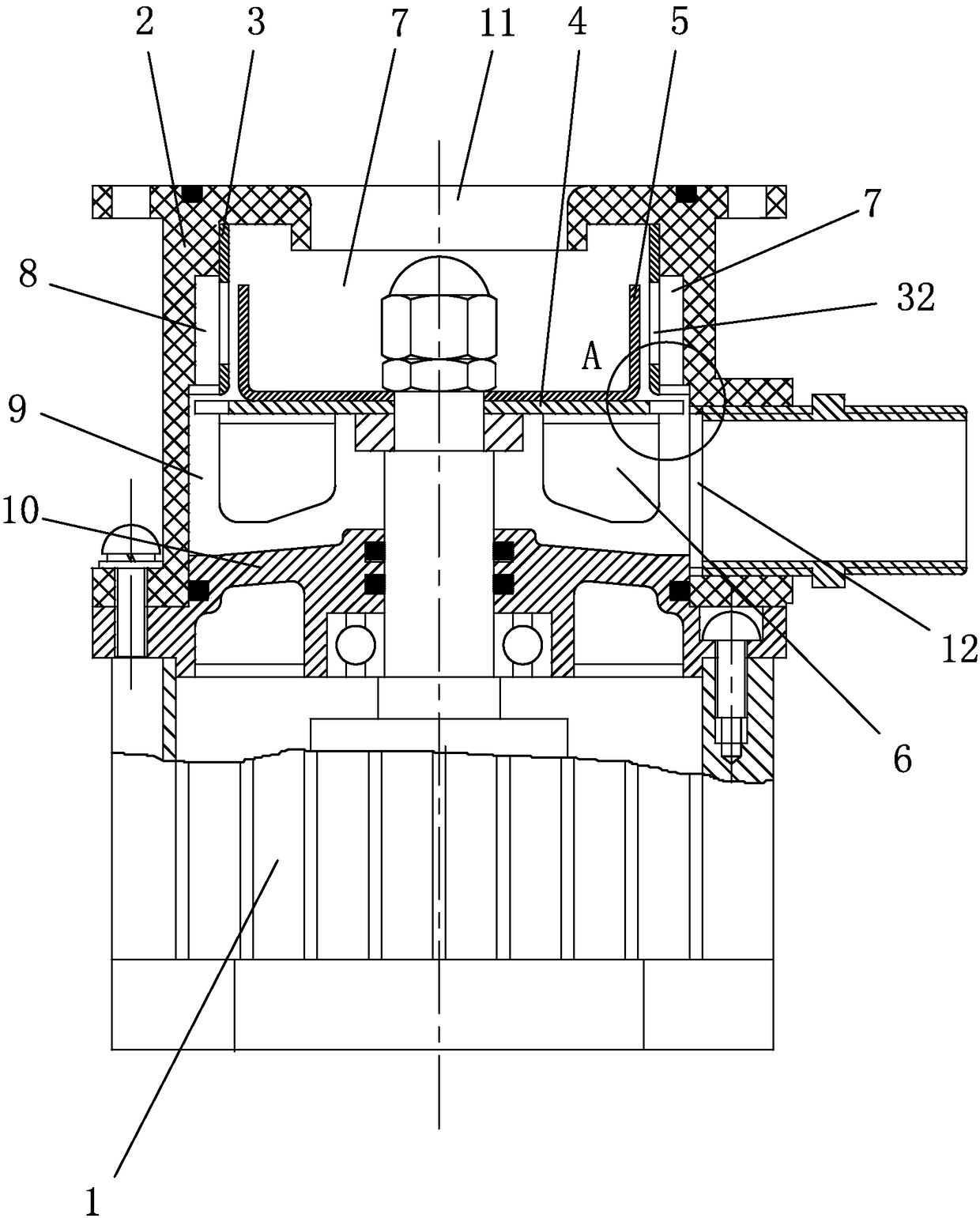

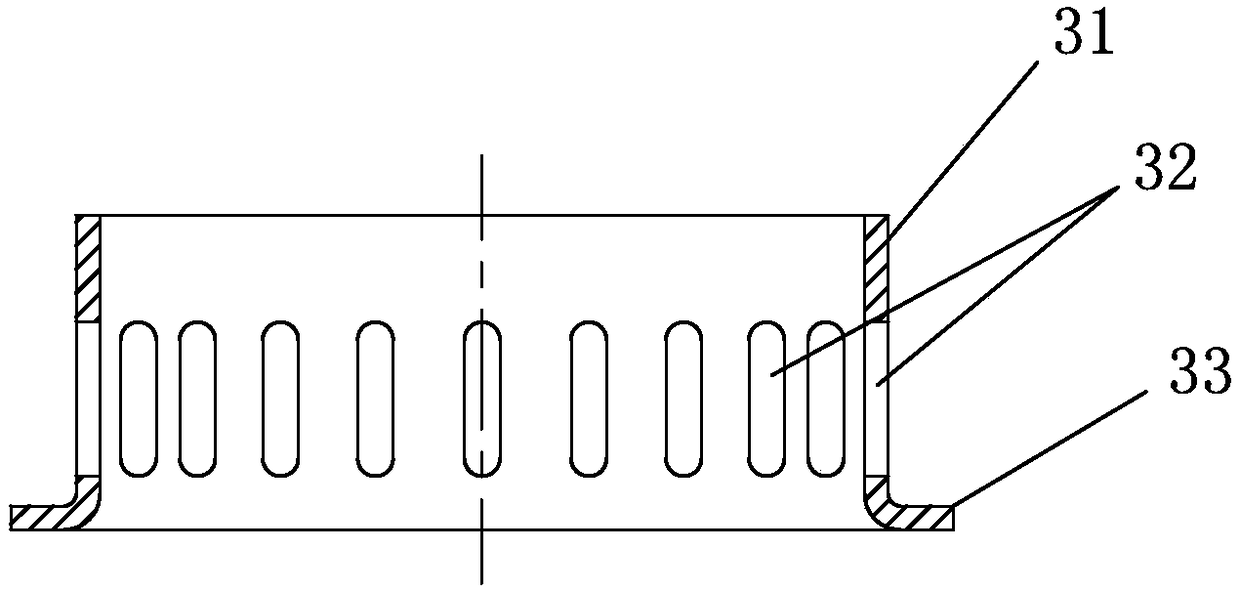

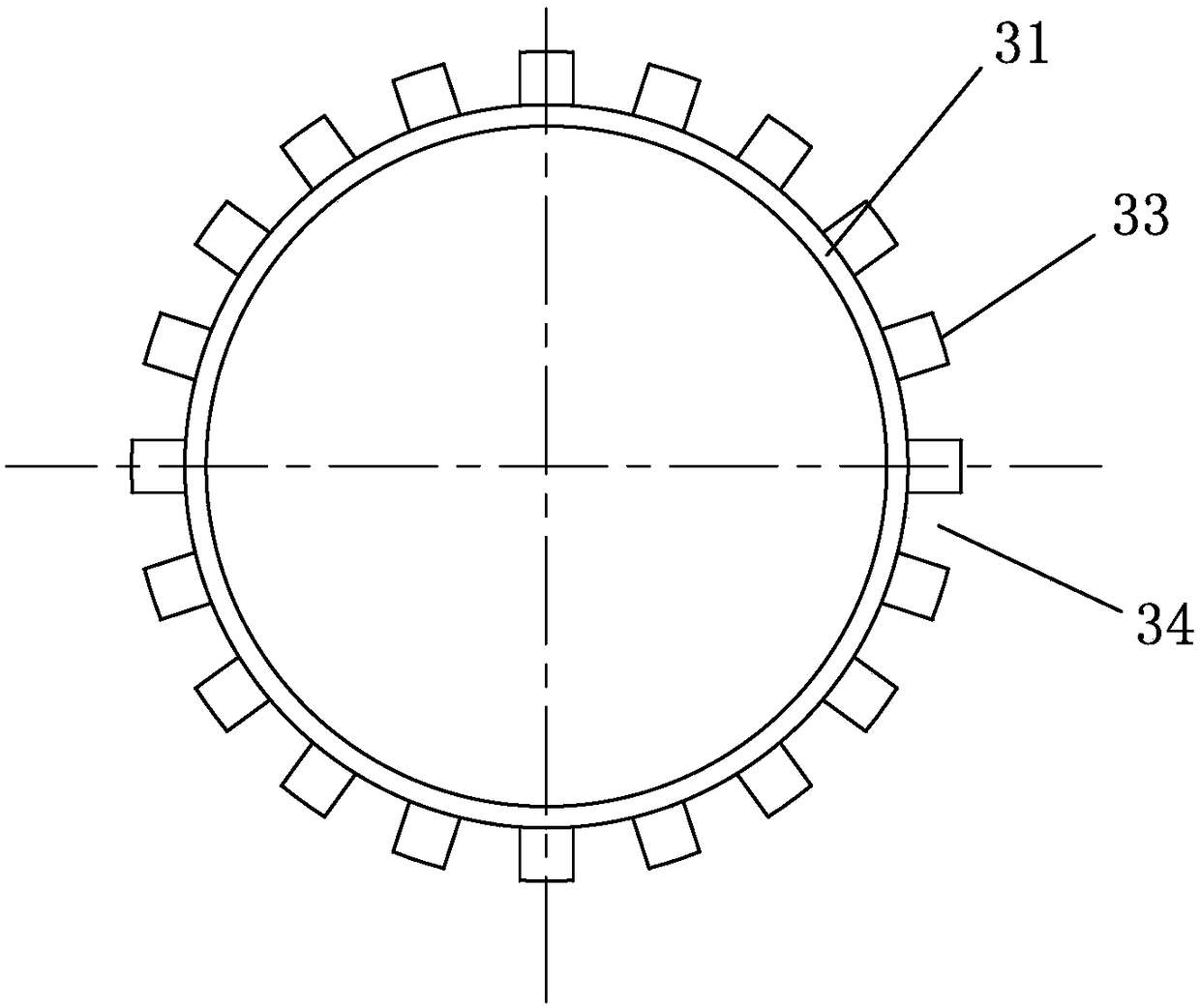

[0030] Embodiment 2: A mechanism for rubbing and removing slag in a dishwasher according to the present invention, as attached Figure 1-12 As shown, it includes a fixed grinding disc seat 2, a fixed grinding disc 3, a moving grinding disc 4 and a motor 1. Several fixed plates 32 are radially arranged on the outer circumference of the fixed grinding disc 3, and several slices 41 are arranged on the outer circumference of the moving grinding disc 4. The slices 41 are located at the Below the fixed piece 32. In the axial direction of the motor shaft, the slice 41 is roughly parallel to the fixed piece 32, and there is a gap between them, and the gap forms an annular kneading and grinding area for kneading and grinding the waste slag entering the gap.

[0031] The speed at which the waste slag processed in the cutting chamber is discharged affects the efficiency of the whole machine; for this reason, the present invention provides a better dual-channel solution to increase the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com