Waste water residue recycle device for road engineering marked line removal vehicle

A road engineering and recycling device technology, applied in road cleaning, cleaning methods, construction, etc., can solve the problems of restricting the promotion and application of high-pressure water removal machines, low degree of automation, poor marking effect, etc., achieving good elasticity and reducing transmission. The effect of strong noise and vibration absorption ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

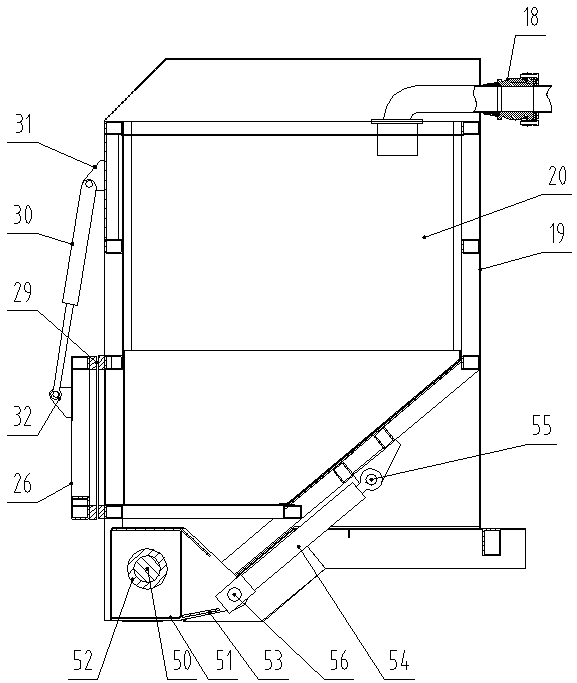

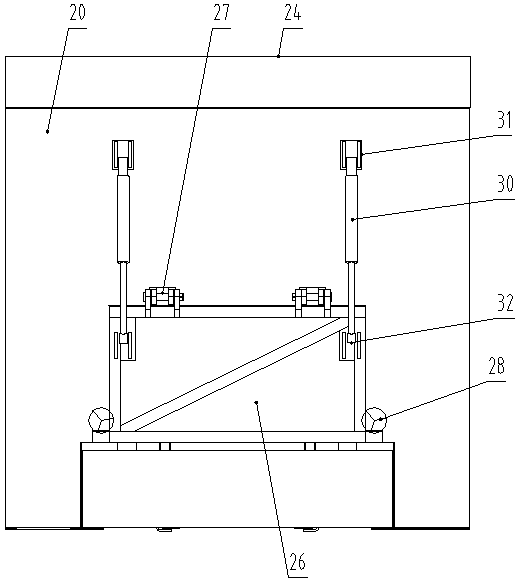

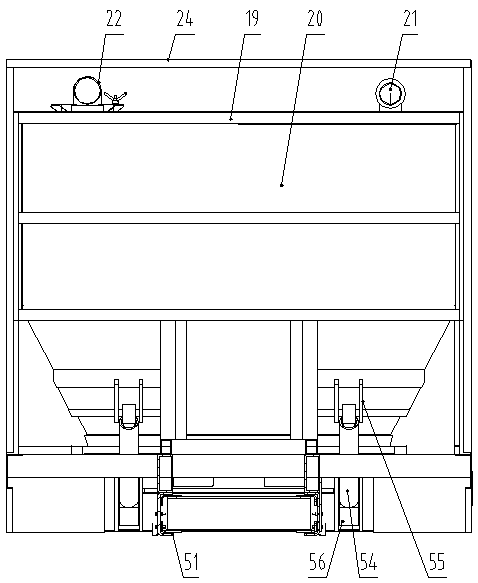

[0024] Such as Figure 1-Figure 5 As shown, the waste water residue recovery device for the road engineering marking line removal vehicle of the present invention includes a vacuum pump (not shown in the figure), a waste water residue storage tank assembly and a soft-connected slag suction pipe assembly 18 .

[0025] The waste water residue storage box assembly includes a three-dimensional frame 19 and a storage box 20 arranged in the three-dimensional frame 19. The top of the storage box 20 is provided with a water slag inlet 21, a vacuum suction port 22 and a maintenance port 23. The top of the storage box 20 A box cover 24 covering the water slag inlet 21, the vacuum suction port 22 and the maintenance port 23 is provided, the dust suction suction port 22 is connected with the suction port of the vacuum tube 17, and the dust suction suction port 22 is connected with a water vapor separation device (not shown in the figure), the storage box 20 is provided with a water slag d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com