Crack source brittle bead surfacing welding wire for marine titanium alloy and preparation method thereof

A technology for surfacing welding wire and titanium alloy, which is applied in the field of marine titanium alloy toughness assessment test materials to achieve the effect of easier welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

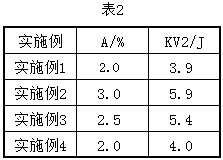

[0021] Embodiment 1: Preparation of crack source brittle bead surfacing welding wire of Ti-2Al-6Mo-5V-3Cr-2Sn marine titanium alloy:

[0022] 1) Weigh the raw materials according to the ingredients listed in Example 1 in Table 1, and mix 2wt.% aluminum element, 6wt.% molybdenum element, 5wt.% vanadium element, 3wt.% chromium element, 2wt.% The tin element and industrial grade 1 sponge titanium are mixed and pressed into electrodes;

[0023] 2) The electrode prepared in step 1) is prepared into an ingot by vacuum consumable arc melting. The vacuum degree of pre-melting should reach 1Pa. In order to ensure uniform alloy composition, the number of vacuum consumable arc melting should not be less than three times;

[0024] 3), the ingot prepared in step 2) is subjected to T β +150℃ blanking, α+β phase zone forging into forgings;

[0025] 4), rolling the forging prepared in step 3) into a wire rod;

[0026] 5) The wire rod prepared in step 4) is drawn into a round wire with a sp...

Embodiment 2

[0027] Example 2: Preparation of crack source brittle bead surfacing welding wire for Ti-7Al-3Mo-5V-2Cr-1Sn alloy marine titanium alloy:

[0028] 1) Weigh the raw materials according to the ingredients listed in Example 2 in Table 1, and mix 7wt.% aluminum element, 3wt.% molybdenum element, 5wt.% vanadium element, 2wt.% chromium element, 1wt.% The tin element and industrial grade 1 sponge titanium are mixed and pressed into electrodes;

[0029] 2) The electrode prepared in step 1) is prepared into an ingot by vacuum consumable arc melting. The vacuum degree of pre-melting should reach 1Pa. In order to ensure uniform alloy composition, the number of vacuum consumable arc melting should not be less than three times;

[0030] 3), the ingot prepared in step 2) is subjected to T β +150℃ blanking, α+β phase zone forging into forgings;

[0031] 4), rolling the forging prepared in step 3) into a wire rod;

[0032] 5) The wire rod prepared in step 4) is drawn into a round wire with ...

Embodiment 3

[0033] Example 3: Preparation of crack source brittle bead surfacing welding wire for Ti-5Al-4Mo-6V-2Cr-5Sn alloy marine titanium alloy:

[0034] 1) Weigh the raw materials according to the ingredients listed in Example 3 in Table 1, and mix 5wt.% aluminum element, 4wt.% molybdenum element, 6wt.% vanadium element, 2wt.% chromium element, 5wt.% The tin element and industrial grade 1 sponge titanium are mixed and pressed into electrodes;

[0035] 2) The electrode prepared in step 1) is prepared into an ingot by vacuum consumable arc melting. The vacuum degree of pre-melting should reach 1Pa. In order to ensure uniform alloy composition, the number of vacuum consumable arc melting should not be less than three times;

[0036] 3), the ingot prepared in step 2) is subjected to T β +150℃ blanking, α+β phase zone forging into forgings;

[0037] 4), rolling the forging prepared in step 3) into a wire rod;

[0038] 5) The wire rod prepared in step 4) is drawn into a round wire with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com