Semi-solid die casting and high-strength-and-toughness aluminum alloy and manufacturing method thereof

A technology for casting aluminum alloys and aluminum alloys, applied in the field of high-strength and tough aluminum alloys for semi-solid die-casting and its preparation, to achieve the effects of improving die-casting process performance, excellent plasticity, and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

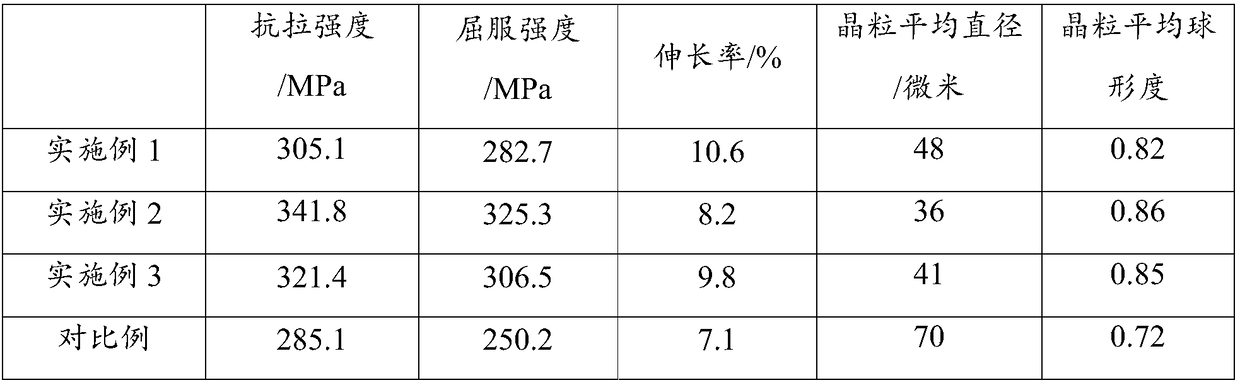

Examples

Embodiment 1

[0051] The high strength and toughness aluminum alloy is composed of the following mass percentages: Si 6.5%, Mg 0.25%, Cu 0.15%, Ti 0.06%, V 0.1%, Sb 0.05%, Yb 0.05%, Fe≤0.2%, the rest are Al and others impurity elements. The preparation method of this high-strength aluminum alloy comprises the following steps:

[0052]1S batching and smelting: According to the above components, 99.9% instant silicon, 99.95% magnesium ingot, 99.99% electrolytic copper, 99.7% aluminum ingot, Al-10Ti alloy, Al-5V alloy, Al-10Sb alloy, Al-5Yb alloy, heat and smelt the prepared raw materials to obtain aluminum alloy liquid, wherein the smelting temperature is 750 ℃;

[0053] 2S semi-solid slurry preparation: the aluminum alloy liquid obtained in step 1S is prepared into an aluminum alloy semi-solid slurry with a temperature of 610° C. under the condition that the mechanical stirring speed is 200 rpm and the stirring time is 8 seconds;

[0054] 3S die-casting: put the aluminum alloy semi-solid s...

Embodiment 2

[0057] The high-strength and tough aluminum alloy is composed of the following mass percentages: Si 7.5%, Mg 0.45%, Cu 0.25%, Ti 0.09%, V 0.15%, Sb 0.1%, Yb 0.1%, Fe≤0.2%, the rest are Al and others For impurity elements, the individual content of other impurity elements is less than 0.05%, and the total content of other impurity elements is less than 0.15%. The preparation method of this high-strength aluminum alloy comprises the following steps:

[0058] 1S batching and smelting: According to the above components, 99.9% instant silicon, 99.95% magnesium ingot, 99.99% electrolytic copper, 99.7% aluminum ingot, Al-10Ti alloy, Al-5V alloy, Al-10Sb alloy, Al-5Yb alloy, heat and smelt the prepared raw materials to obtain aluminum alloy liquid, wherein the smelting temperature is 700 ℃;

[0059] Preparation of 2S semi-solid slurry: After refining, degassing and removing slag from the aluminum alloy liquid obtained in step 1S with hexachloroethane, the aluminum alloy liquid is pre...

Embodiment 3

[0063] The high-strength and tough aluminum alloy is composed of the following mass percentages: Si 9.5%, Mg 0.65%, Cu 0.2%, Ti 0.07%, V 0.12%, Sb 0.06%, Yb 0.08%, Fe≤0.2%, and the rest are Al and For other impurity elements, the individual content of other impurity elements is less than 0.05%, and the total content of other impurity elements is less than 0.15%. The preparation method of this high-strength aluminum alloy comprises the following steps:

[0064] 1S batching and smelting: According to the above components, 99.9% instant silicon, 99.95% magnesium ingot, 99.99% electrolytic copper, 99.7% aluminum ingot, Al-10Ti alloy, Al-5V alloy, Al-10Sb alloy, Al-5Yb alloy, heat and smelt the prepared raw materials to obtain aluminum alloy liquid, wherein the smelting temperature is 700 ℃;

[0065] 2S semi-solid slurry preparation: After refining, degassing and removing slag from the aluminum alloy liquid obtained in step 1S with hexachloroethane, the aluminum alloy liquid is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com