Electrochemical device and method for manufacturing same

A manufacturing method and electrochemical technology, applied in the direction of electrochemical generators, electrolyte storage battery manufacturing, hybrid/electric double layer capacitor manufacturing, etc., can solve the problems of small capacity and difficulty in achieving high capacity, and achieve excellent reliability and long-term The effect of stable charge and discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

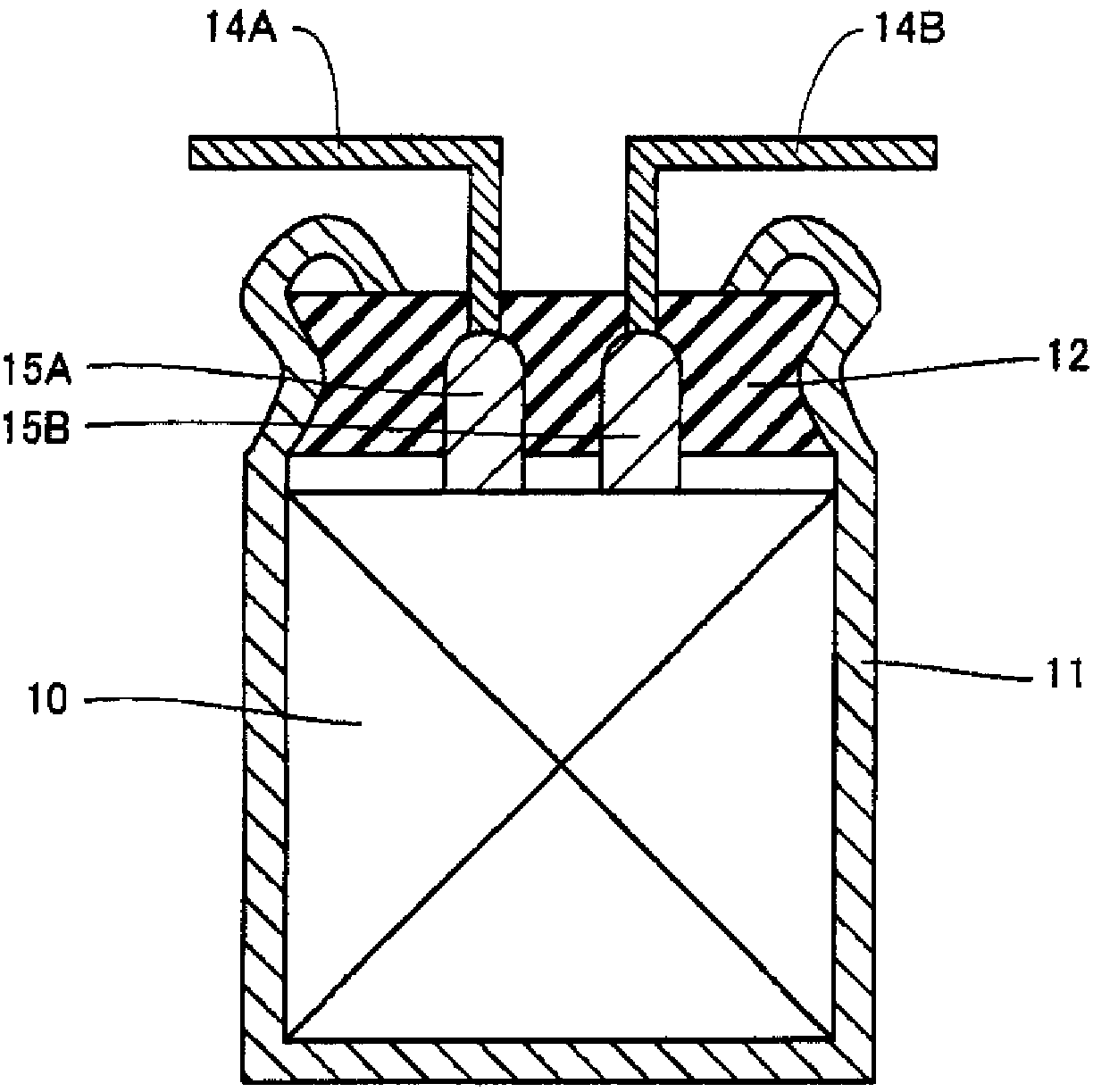

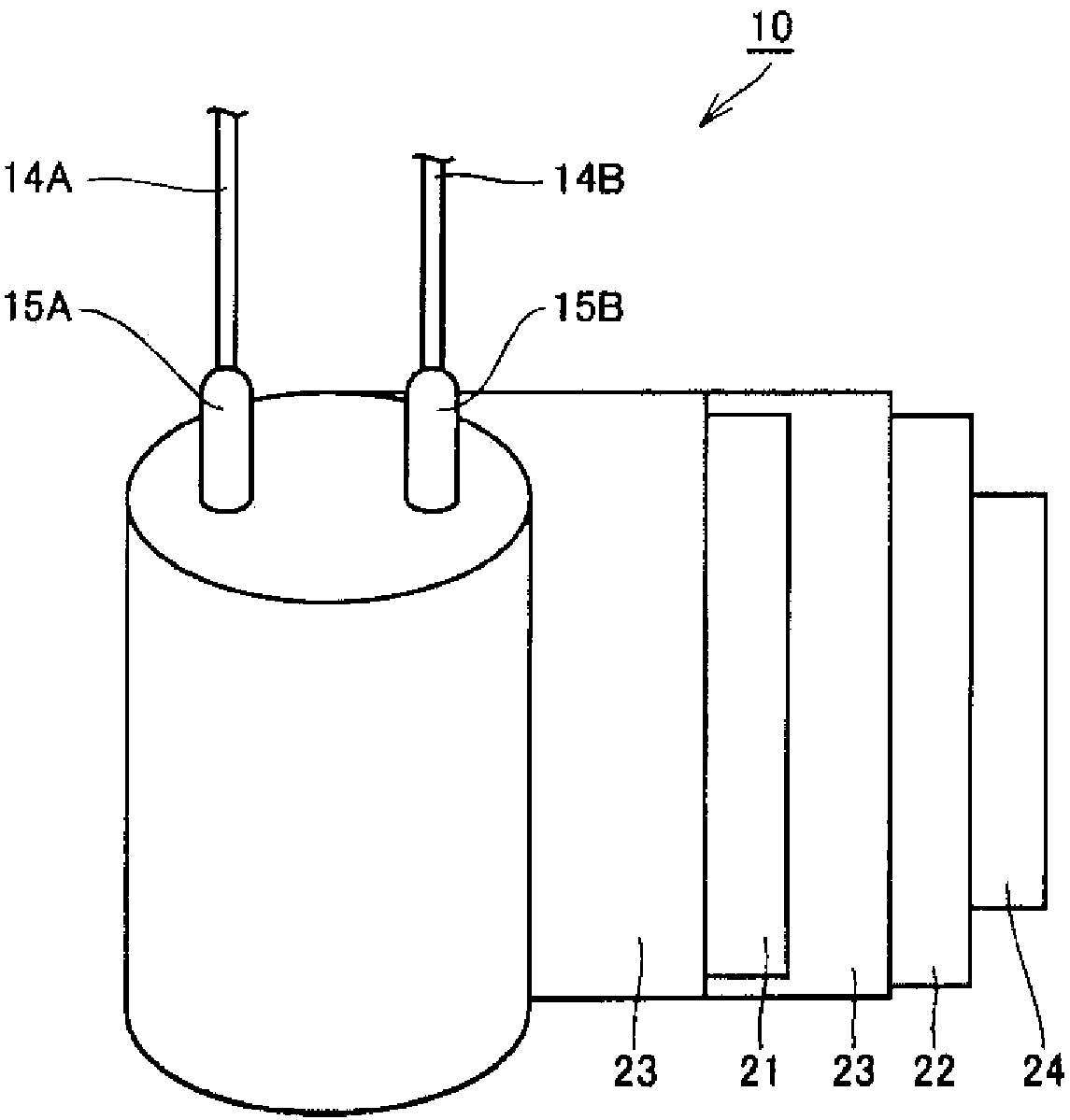

[0071] (1) Production of positive electrode

[0072] An aluminum foil with a thickness of 30 μm was prepared as a positive electrode current collector. On the other hand, as the first solution, a solution containing an aniline concentration of 1 mol / L and a sulfuric acid concentration of 2 mol / L was prepared. The pH of the first solution was adjusted to 0.6, and the temperature was adjusted to 25°C.

[0073] Immerse the positive electrode current collector and the counter electrode made of stainless steel in the first solution at 10mA / cm 2 The current density of electrolytic polymerization was carried out for 20 minutes, so that the sulfate ion (SO 4 2- ) conductive polymer (polyaniline) film attached to the entire surface of the front and back of the positive electrode current collector.

[0074] The positive electrode current collector and the counter electrode having the conductive polymer film doped with sulfate ions were taken out from the first solution, and immersed...

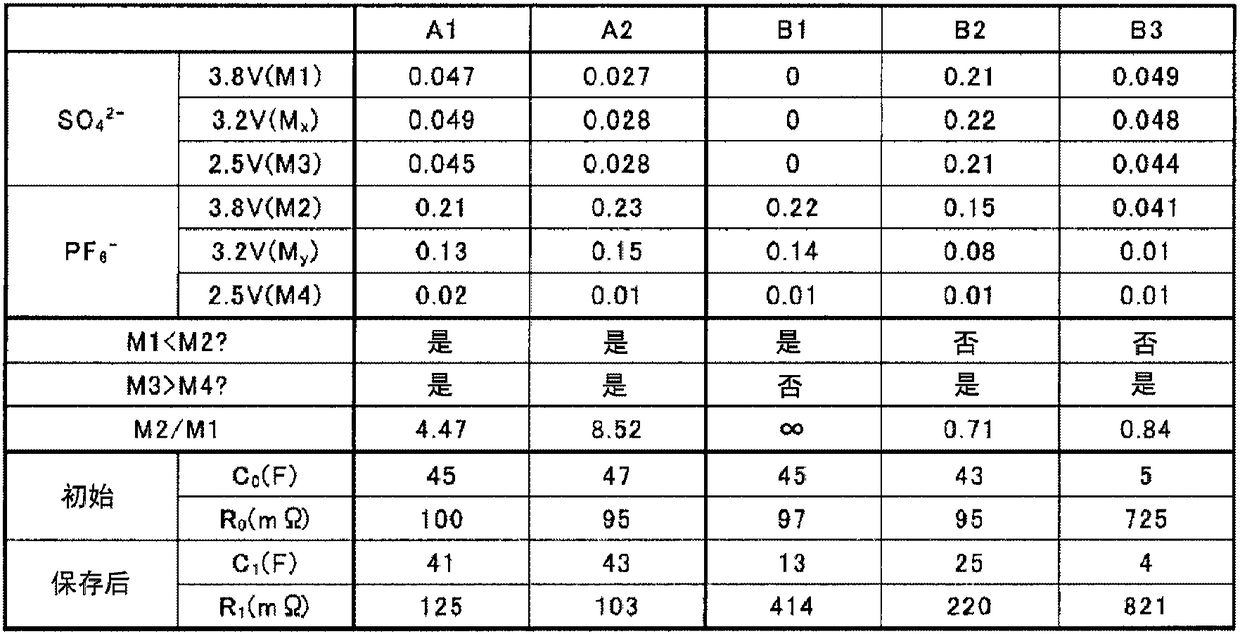

Embodiment 2

[0084] In the production of the positive electrode material layer, the reduction condition of the conductive polymer by the reverse current was changed to a current density of 2mA / cm 2 And 15 minutes, except that, it carried out similarly to Example 1, and produced the electrochemical device (A2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com