Variable modulus personalized femoral stem prosthesis and manufacturing method thereof

A femoral stem and prosthesis technology, applied in the direction of prosthesis, femoral head, additive manufacturing, etc., can solve the problems of reduced mineral density in bone, easy to produce fretting, single form, etc., to enhance stability and prevent subsidence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

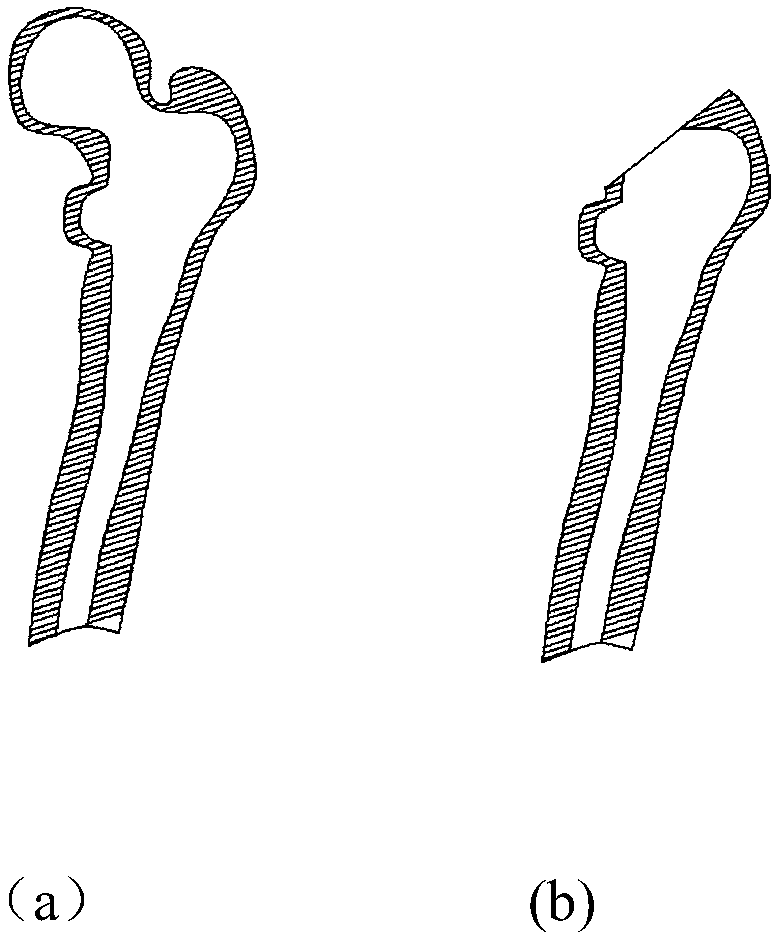

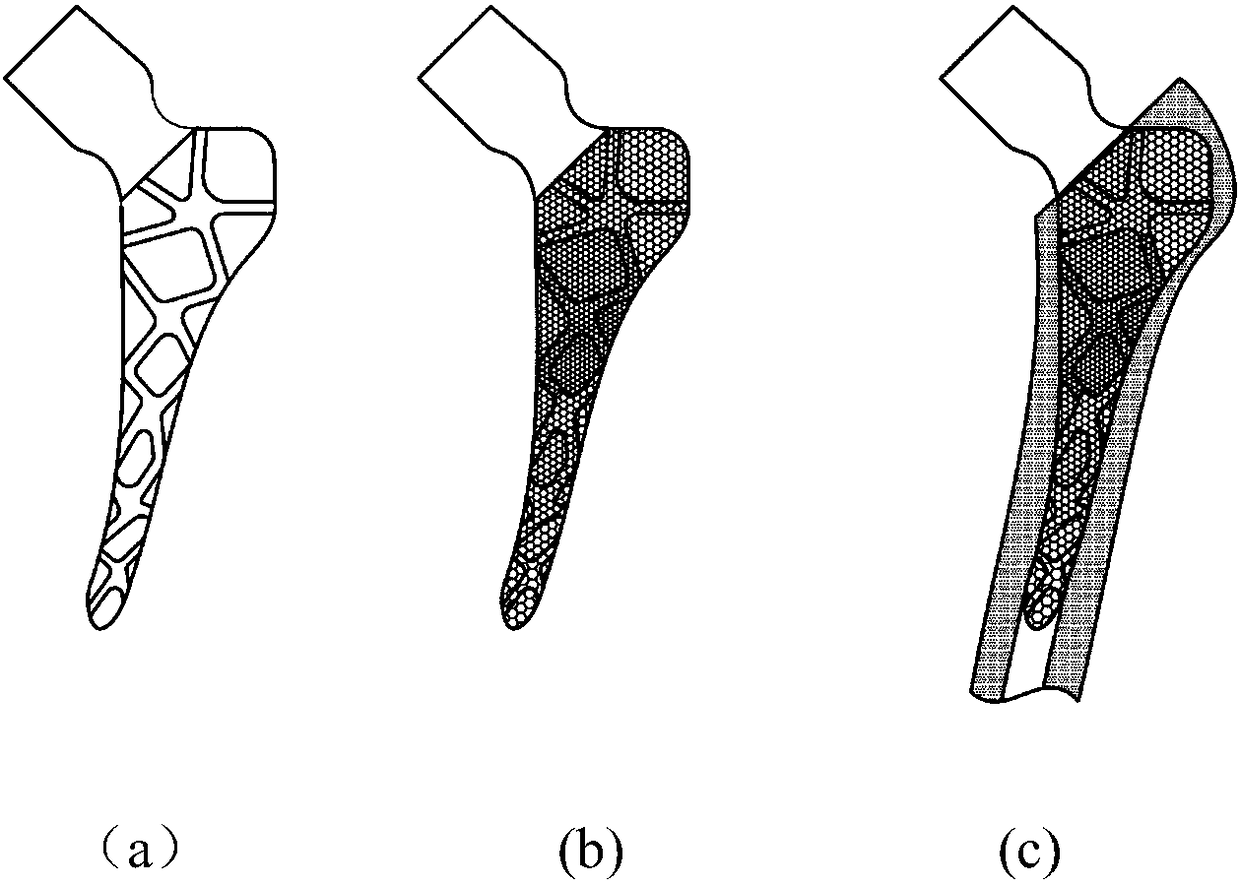

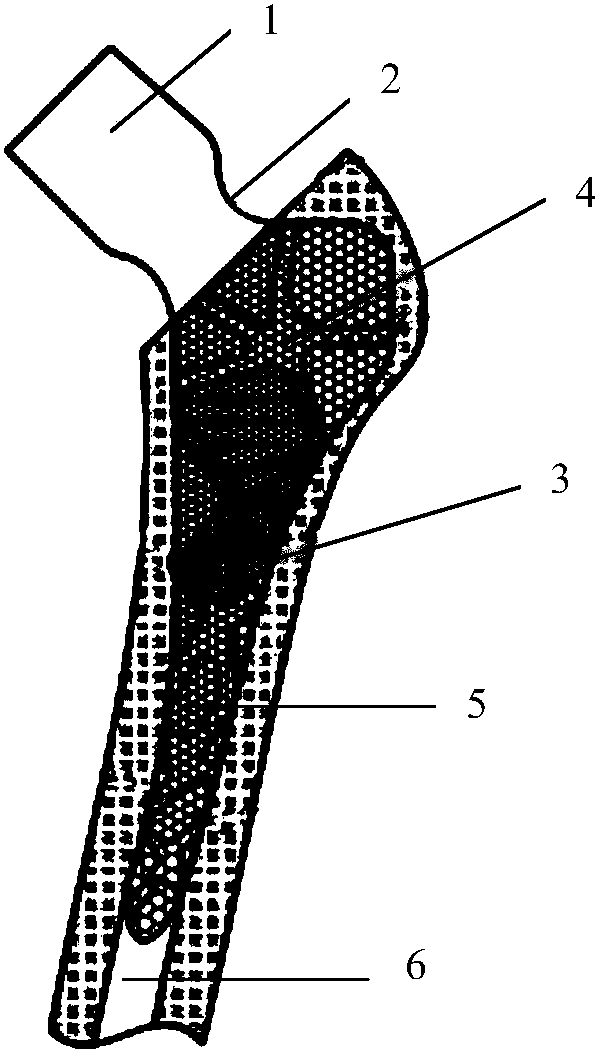

[0041] Such as figure 1 (a)- figure 1 (b), figure 2 (a)- figure 2 (c) and image 3 As shown, a variable modulus personalized femoral stem prosthesis of the present invention includes: comprising a femoral stem head 1, a neck 2 and a medullary cavity 3, the outside of the medullary cavity matches the bone marrow cavity 6, The interior is equipped with a topology-optimized space main frame 4 and a porous structure 5 filling the space structure. The variable modulus personalized femoral stem prosthesis is prepared by laser selective melting. After the prosthesis is sterilized, the filling can induce bone ingrowth. Degradation of hydroxyl composites.

[0042] According to the patient's CT / MRI medical image data, the gray value of the image is used to mask, and the masked part is stacked to form a three-dimensional proximal femur model. After the force analysis and bone quality analysis of the proximal femur are completed, the head of the femoral stem is designed and Combine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com