Ultra-low-pressure-drop activated carbon adsorption tank

An activated carbon adsorption tank and activated carbon adsorption technology are used in gas treatment, membrane technology, dispersed particle separation, etc., which can solve problems such as large pressure drop, and achieve the effect of reduced adsorption pressure and low equipment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

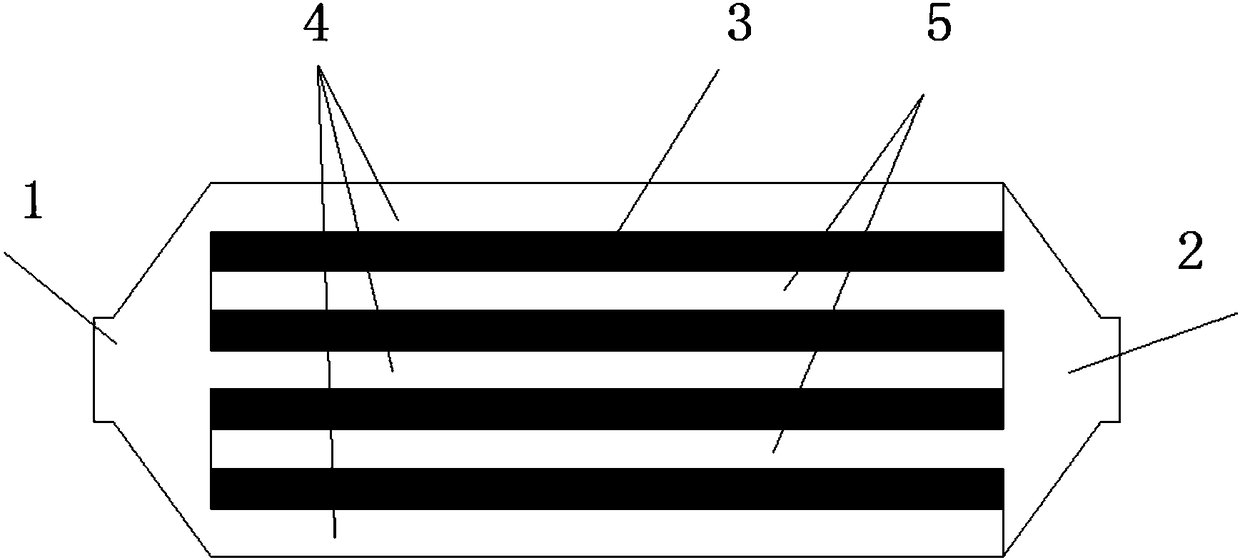

[0024] An activated carbon adsorption tank with ultra-low pressure drop, its structure is shown in figure 1 , The activated carbon tank is a cuboid activated carbon adsorption tank, and the size of the body is 2000mm long, 1000mm wide and 1300mm high. The air inlet (1) is a square air inlet with a size of 500*500, and the size of the air outlet (2) is consistent with the size of the air inlet (1). There are four activated carbon adsorption layers (3) placed horizontally and parallel in the activated carbon tank. The size of the single-layer activated carbon adsorption layer is 2000mm long, 1000mm wide, and 200mm high. The distance between two adjacent activated carbon adsorption layers is 100mm. The distance between the adsorption layer and the upper wall of the adsorption tank is 100 mm, and the distance between the bottom activated carbon adsorption layer and the lower wall of the adsorption tank is 100 mm. 2000m3 / h VOC waste gas enters the adsorption tank through the air i...

Embodiment 2

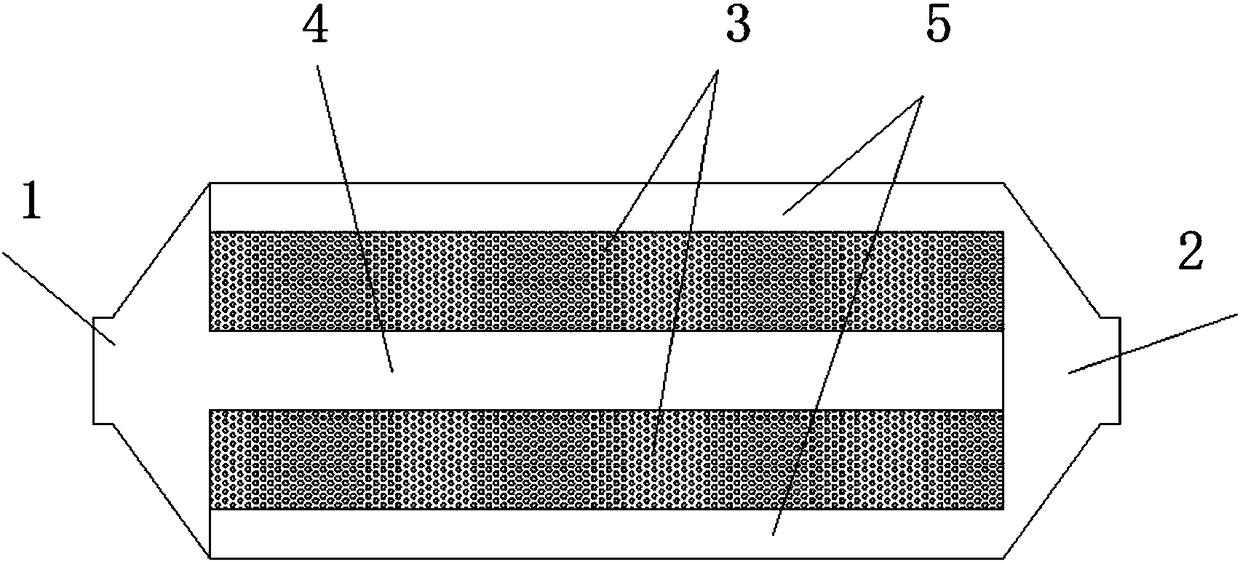

[0026] An activated carbon adsorption tank with ultra-low pressure drop, its structure is shown in figure 2 , The activated carbon tank is a cuboid activated carbon adsorption tank, and the size of the body is 2000mm long, 1000mm wide and 1300mm high. The air inlet (1) is a square air inlet with a size of 500*500, and the size of the air outlet (2) is consistent with the size of the air inlet (1). There are two activated carbon adsorption layers (3) placed horizontally and parallel in the activated carbon tank. The size of the single-layer activated carbon adsorption layer is 2000mm long, 1000mm wide, and 400mm high. The distance between two adjacent activated carbon adsorption layers is 300mm. The distance between the adsorption layer and the upper wall of the adsorption tank is 200 mm, and the distance between the bottom activated carbon adsorption layer and the lower wall of the adsorption tank is 200 mm. 3000m3 / h of VOC exhaust gas enters the adsorption tank through the ...

Embodiment 3

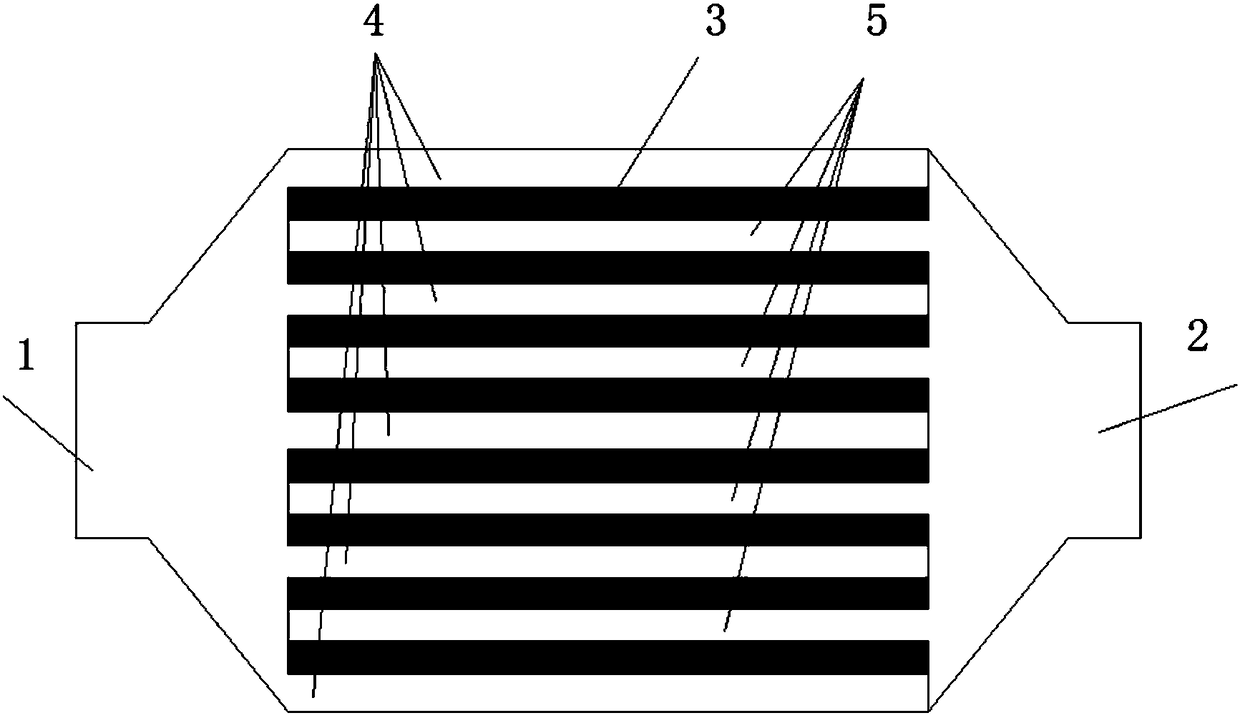

[0028] An activated carbon adsorption tank with ultra-low pressure drop, its structure is shown in image 3 , The activated carbon tank is a cuboid activated carbon adsorption tank, and the size of the body is 2000mm long, 2000mm wide, and 2100mm high. The air inlet (1) is a square air inlet with a size of 800*1000, and the size of the air outlet (2) is the same as that of the air inlet (1). There are 8 activated carbon adsorption layers (3) placed horizontally and parallel in the activated carbon tank. The size of the single-layer activated carbon adsorption layer is 2000mm long, 2000mm wide, and 150mm high. The distance between two adjacent activated carbon adsorption layers is 100mm. The distance between the adsorption layer and the upper wall of the adsorption tank is 100 mm, and the distance between the bottom activated carbon adsorption layer and the lower wall of the adsorption tank is 100 mm. 10000m3 / h VOC exhaust gas enters the adsorption tank through the air inlet (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com