Reconstituted tobacco smashing device

A technology for pulverizing equipment and reconstituting tobacco leaves, which is applied in lighting and heating equipment, tobacco, tobacco preparation, etc., can solve the problems of internal knife damage, single function, poor personnel protection effect, etc., to facilitate cutting operations and avoid excessive force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

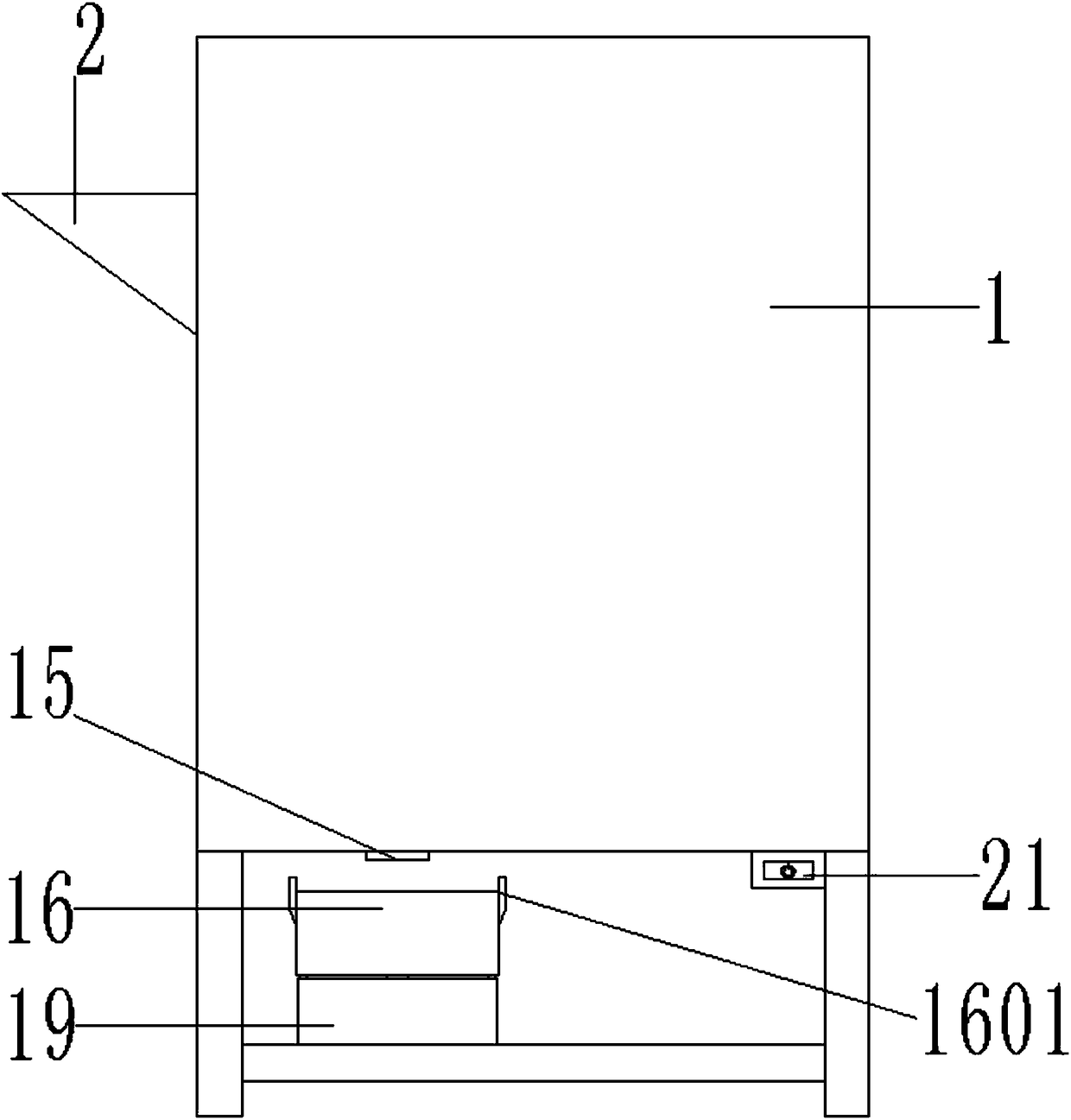

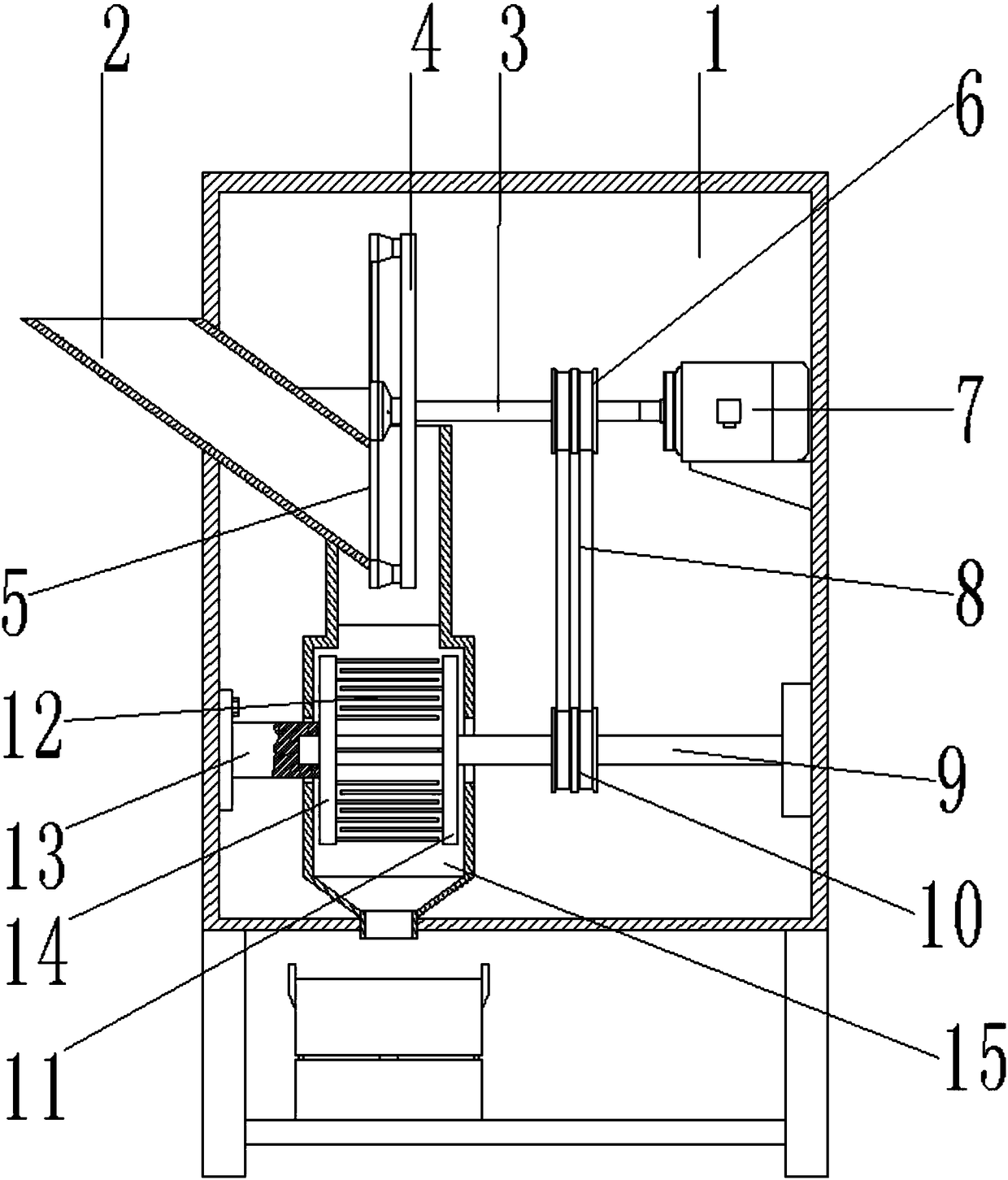

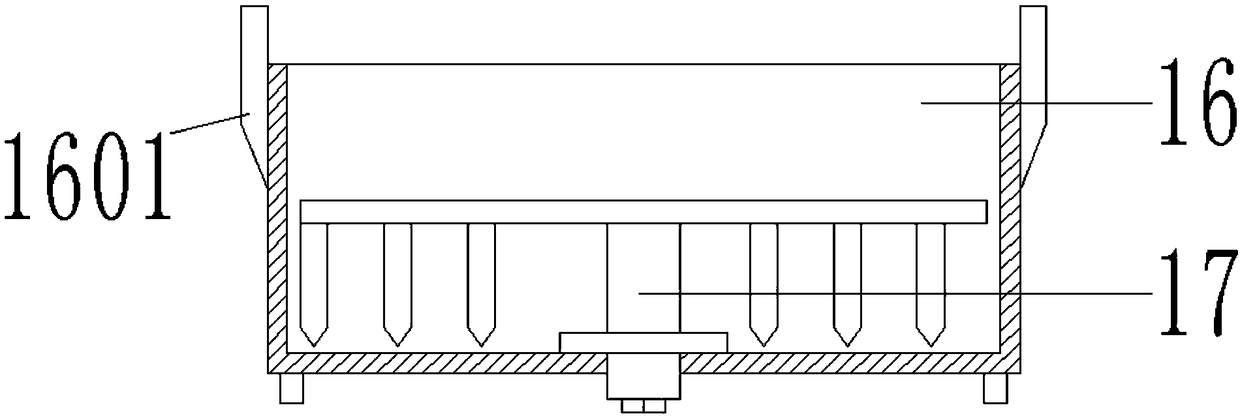

[0034] as attached figure 1 to attach Figure 9 Shown:

[0035] The invention provides reconstituted tobacco leaf crushing equipment, comprising a main box 1, an inclined channel 2, a driving shaft 3, a blade mounting plate 4, a cutting knife 5, a driving wheel 6, a motor 7, a conveyor belt 8, a driven shaft 9, a driven wheel 10, a rotary Wheel 11, tearing column 12, fixed shaft 13, fixed wheel 14, falling cavity 15, drying tank 16, handle 1601, stirring shaft 17, heating plate 18, support box 19, stirring motor 20 and master control power switch 21, described The inclined channel 2 is installed on the main chassis 1, and the motor 7 is installed in the main chassis 1, the driving shaft 3 is installed on the rotating shaft of the motor 7, and one end of the driving shaft 3 is rotatably connected to the left wall of the inner cavity of the main chassis 1, The driving wheel 6 is installed on the driving shaft 3, and the driving wheel 6 is connected to the driven wheel 10 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com