Method and equipment for spraying marking on steel pipes

A steel pipe and marking technology, applied in the directions of copying/marking methods, spraying devices, liquid spraying devices, etc., can solve the problems of low marking efficiency, easy falling off, unclear fonts, etc., to shorten marking time, prevent rust from falling off, The effect of the logo is clear and not blurred

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

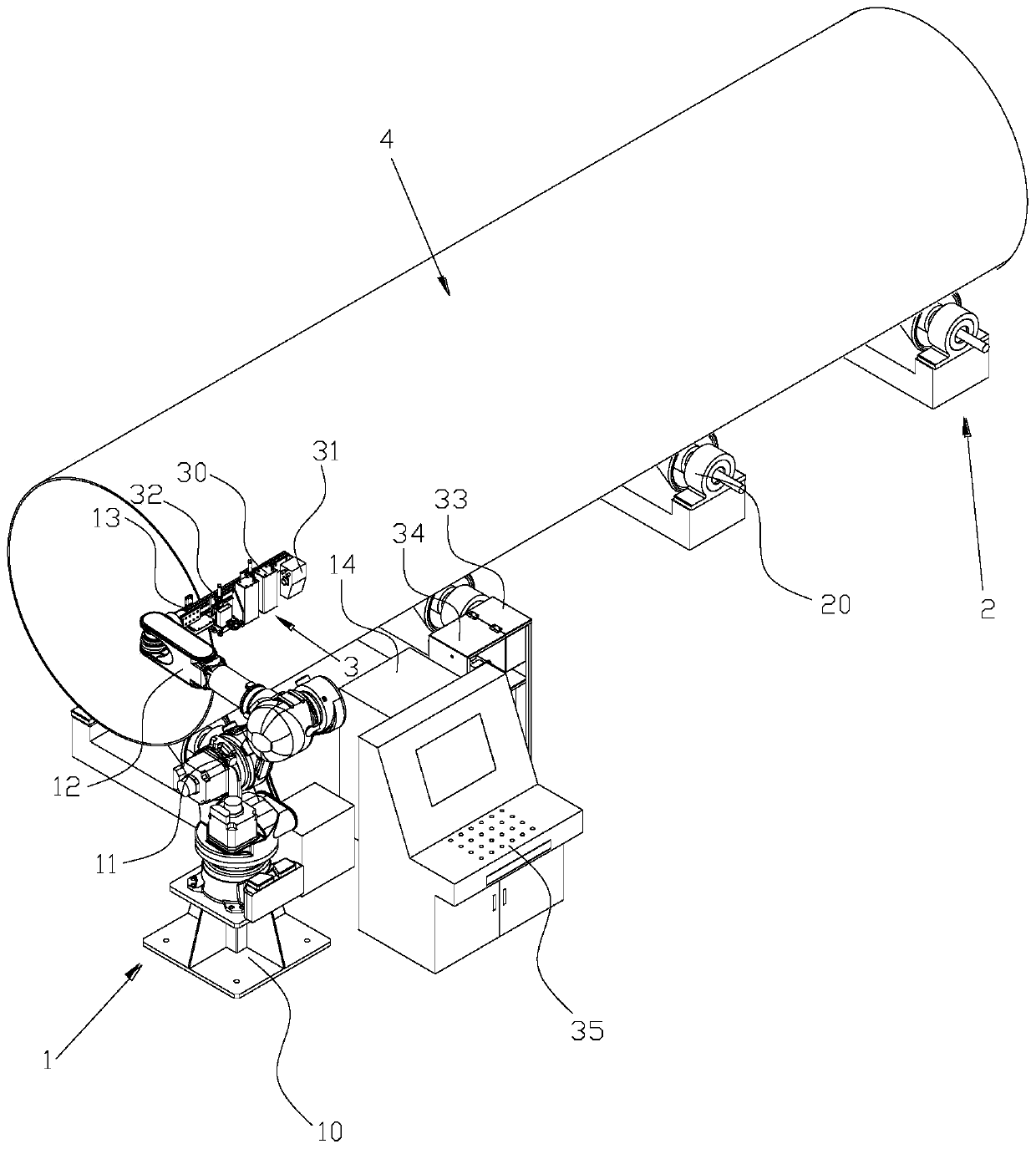

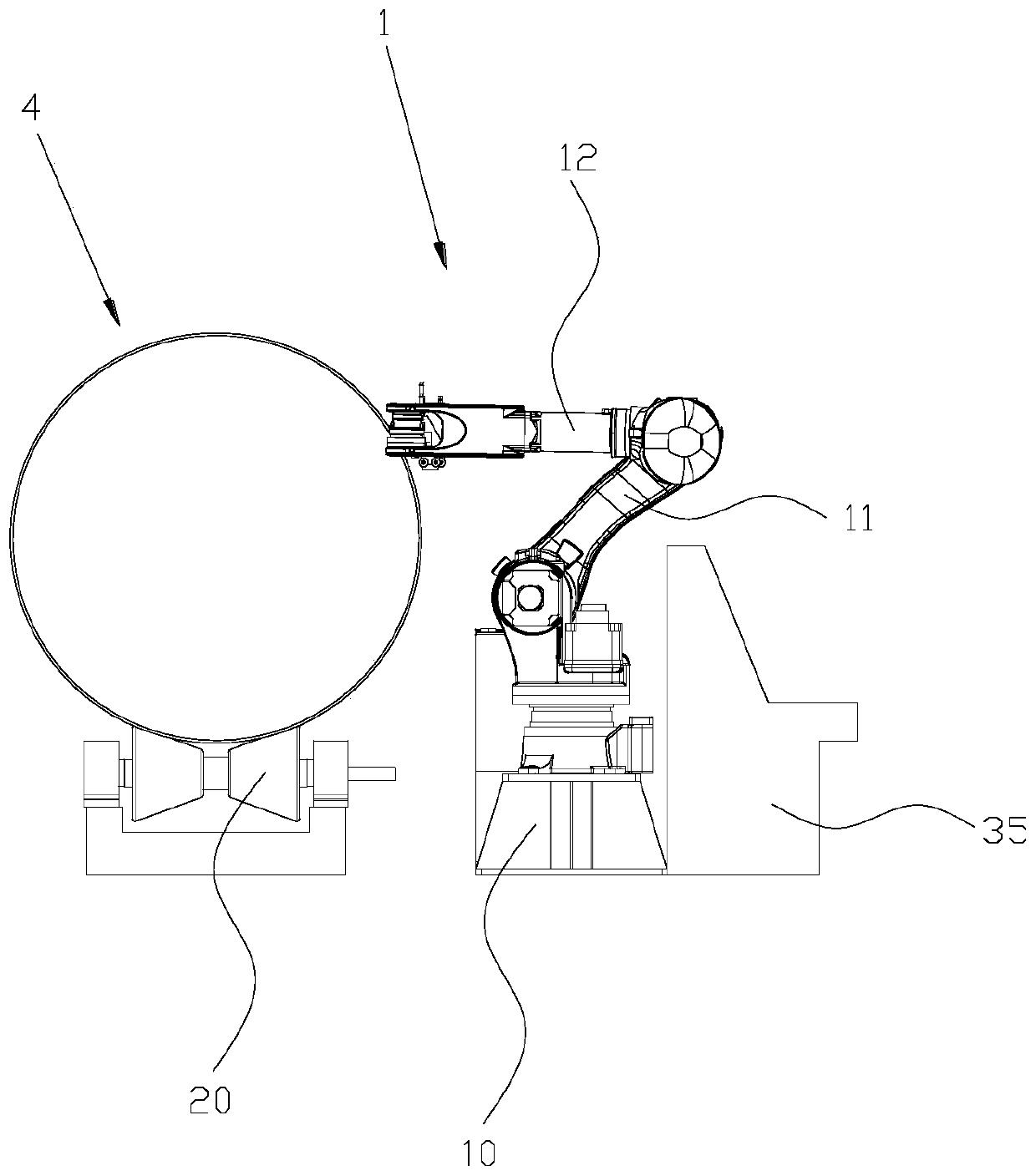

[0047] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

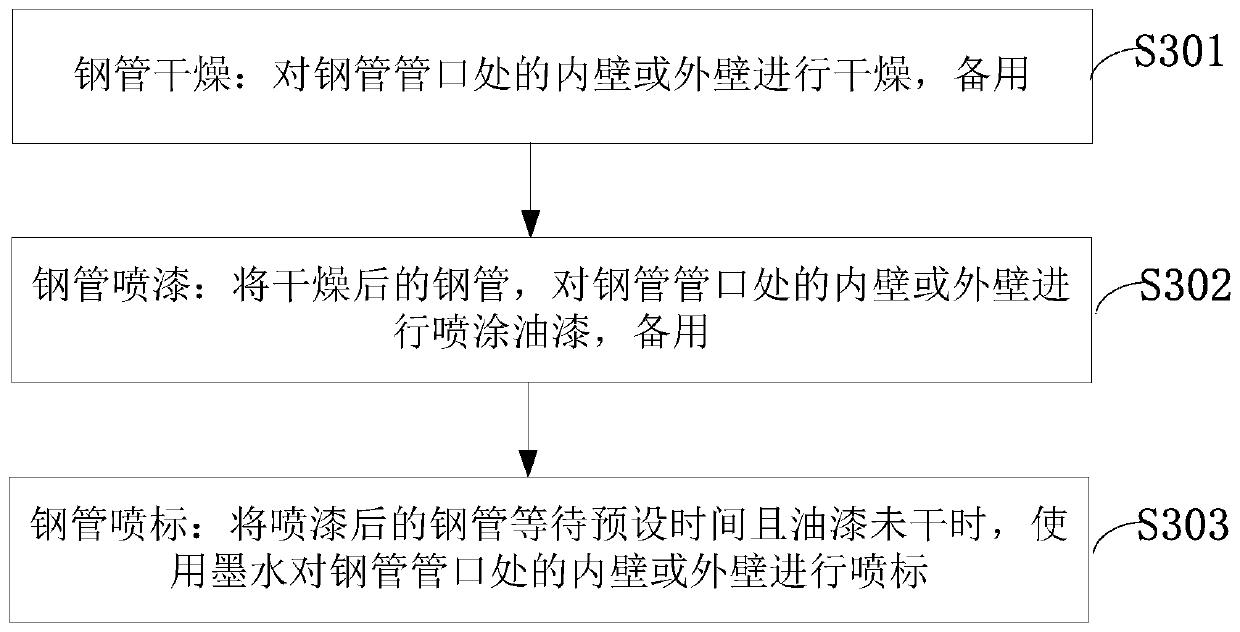

[0048] see figure 1 , the invention provides a steel pipe marking method, said method comprising the following steps:

[0049] steel pipe drying

[0050] Dry the inner wall or outer wall of the steel pipe nozzle, and set aside;

[0051] steel pipe painting

[0052] The dried steel pipe is sprayed with paint on the inner wall or outer wall of the steel pipe nozzle, and it is set aside;

[0053] Steel pipe spray label

[0054] When the painted steel pipe is waiting for a preset time and the paint is not dry, ink is used to spray the inner or outer wall of the steel pipe nozzle, and the ink includes the following components by weight percentage:

[0055] Cyclohexanone: 20-30%,

[0056] Titanium dioxide: >10%.

[0057] Dry the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com