A kind of low-odor spray-molded automobile instrument panel material and preparation method thereof

A low-odor technology for automotive dashboards, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of high viscosity of polyester polyols, high elongation at break, unfavorable processing and production of dashboards, etc., and achieve a good surface Performance, the effect of excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The parts mentioned in the following examples all refer to parts by weight.

[0041] The following technical indicators are evaluated for the sprayed polyurethane instrument panel obtained in each of the following embodiments. Surface properties: abrasion resistance, solvent resistance (petroleum ether, alcohol, ammonia detergent, surfactant),

[0042] High temperature color fastness;

[0043] Mechanical properties: tensile strength, elongation at break;

[0044] Emissions: odor, VOC, condensation, formaldehyde, flame retardant properties.

[0045] Aging performance: humidity aging (70°C, 95% humidity, 500h), heat aging (120°C, 500h), environmental cycle ((+80 / -40)°C);

[0046] The above tests are carried out in accordance with the German Volkswagen Standard TL52296 and its referenced standards.

[0047] The following components are used in the examples of this application:

[0048] Water-based two-component in-mold paint

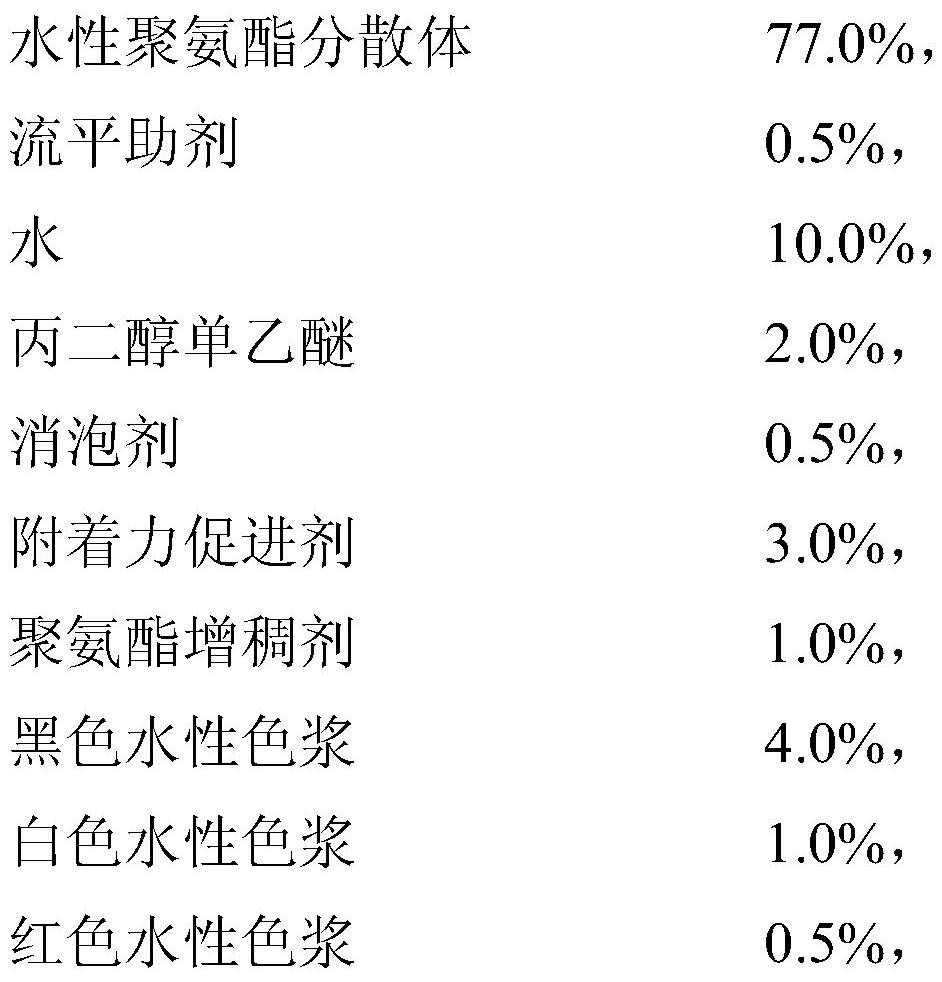

[0049] Wherein, preferred formula comprise...

Embodiment 3

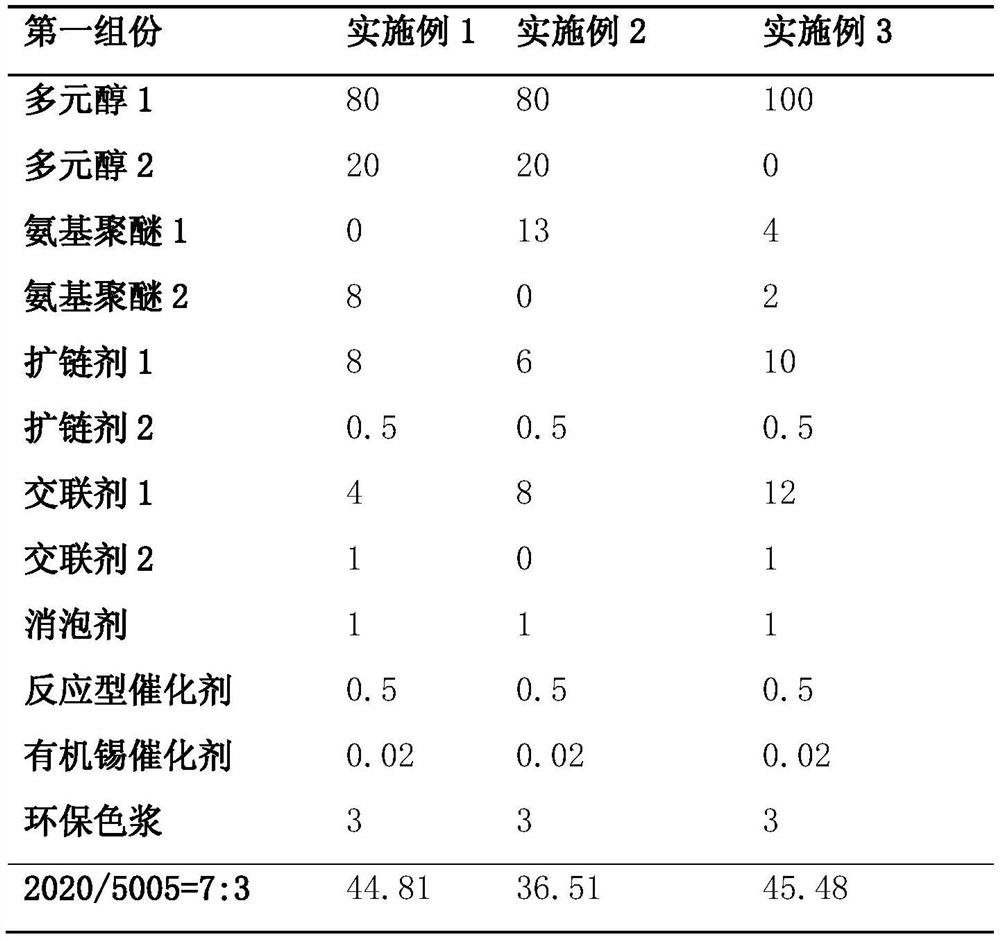

[0078] The formula of table 1 embodiment 1-3

[0079]

[0080] Samples were prepared according to the formulations of Examples 1-3 in Table 1. For each sample, each test was repeated three times, and the average value was obtained.

[0081] The abrasion resistance performance of table 2 embodiment 1-3 abrasion resistance performance

[0082] Example Example 1 Example 2 Example 3 Dry grinding 100 times Grade 4‐5 Grade 4‐5 Grade 4‐5 petroleum ether Grade 4‐5 Grade 4‐5 Grade 4‐5 alcohol level 4 level 4 level 4 Ammonia Glass Cleaner Grade 4‐5 Grade 4‐5 Grade 4‐5 Surfactant Grade 4‐5 Grade 4‐5 Grade 4‐5

[0083] Table 3 embodiment 1-3 solvent resistance performance

[0084]

[0085] The emitting performance of table 4 embodiment 1-3

[0086] Example Example 1 Example 2 Example 3 Condensed mg 0.49 0.50 0.48 Formaldehydemg / kg 0.74 0.78 0.72 Total carbon ugC / g 8.50 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com