Low-smell plastic molding automobile instrument panel material and preparation method thereof

A technology for automobile instrument panel and low odor, which is applied in the field of spray plastic material and its preparation, and the field of spray molding automobile instrument panel material. problem, to achieve the effect of good surface performance and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The parts mentioned in the following examples all refer to parts by weight.

[0041] The following technical indicators are evaluated for the sprayed polyurethane instrument panel obtained in each of the following embodiments. Surface properties: abrasion resistance, solvent resistance (petroleum ether, alcohol, ammonia detergent, surfactant),

[0042] High temperature color fastness;

[0043] Mechanical properties: tensile strength, elongation at break;

[0044] Emissions: odor, VOC, condensation, formaldehyde, flame retardant properties.

[0045] Aging performance: humidity aging (70°C, 95% humidity, 500h), heat aging (120°C, 500h), environmental cycle ((+80 / -40)°C);

[0046] The above tests are carried out in accordance with the German Volkswagen Standard TL52296 and its referenced standards.

[0047] The following components are used in the examples of this application:

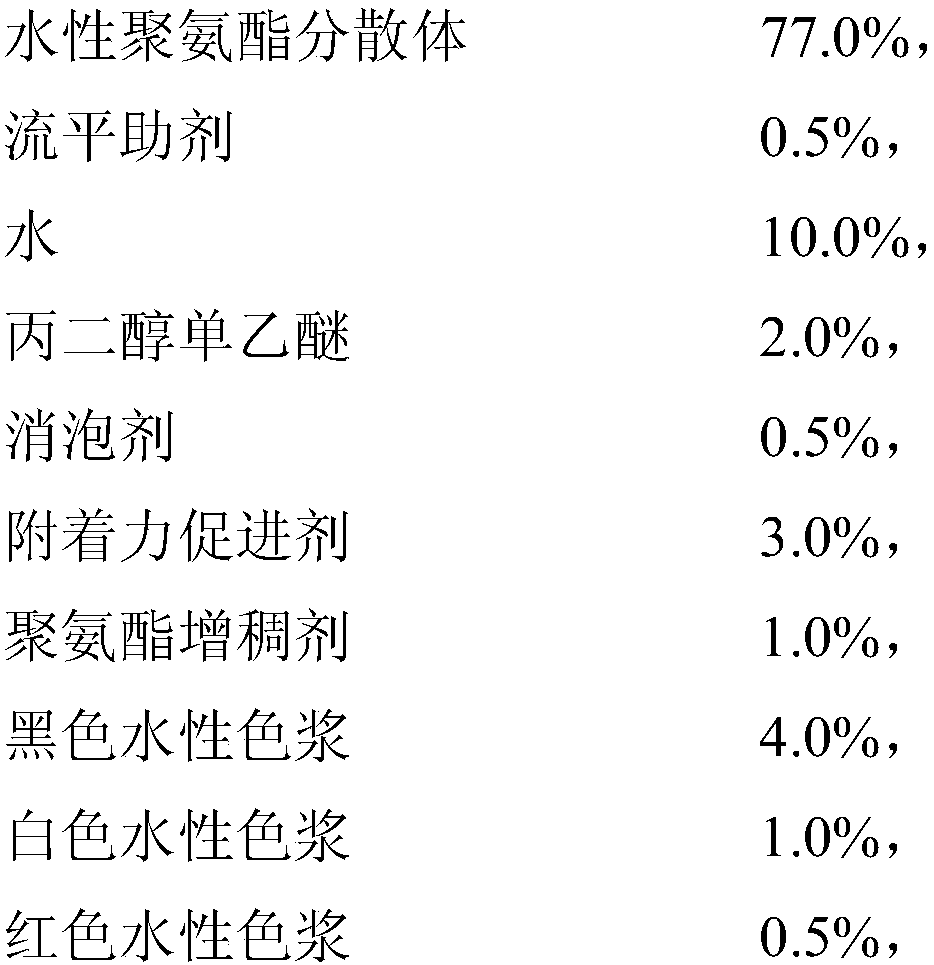

[0048] Water-based two-component in-mold paint

[0049] Wherein, preferred formula comprise...

Embodiment 3

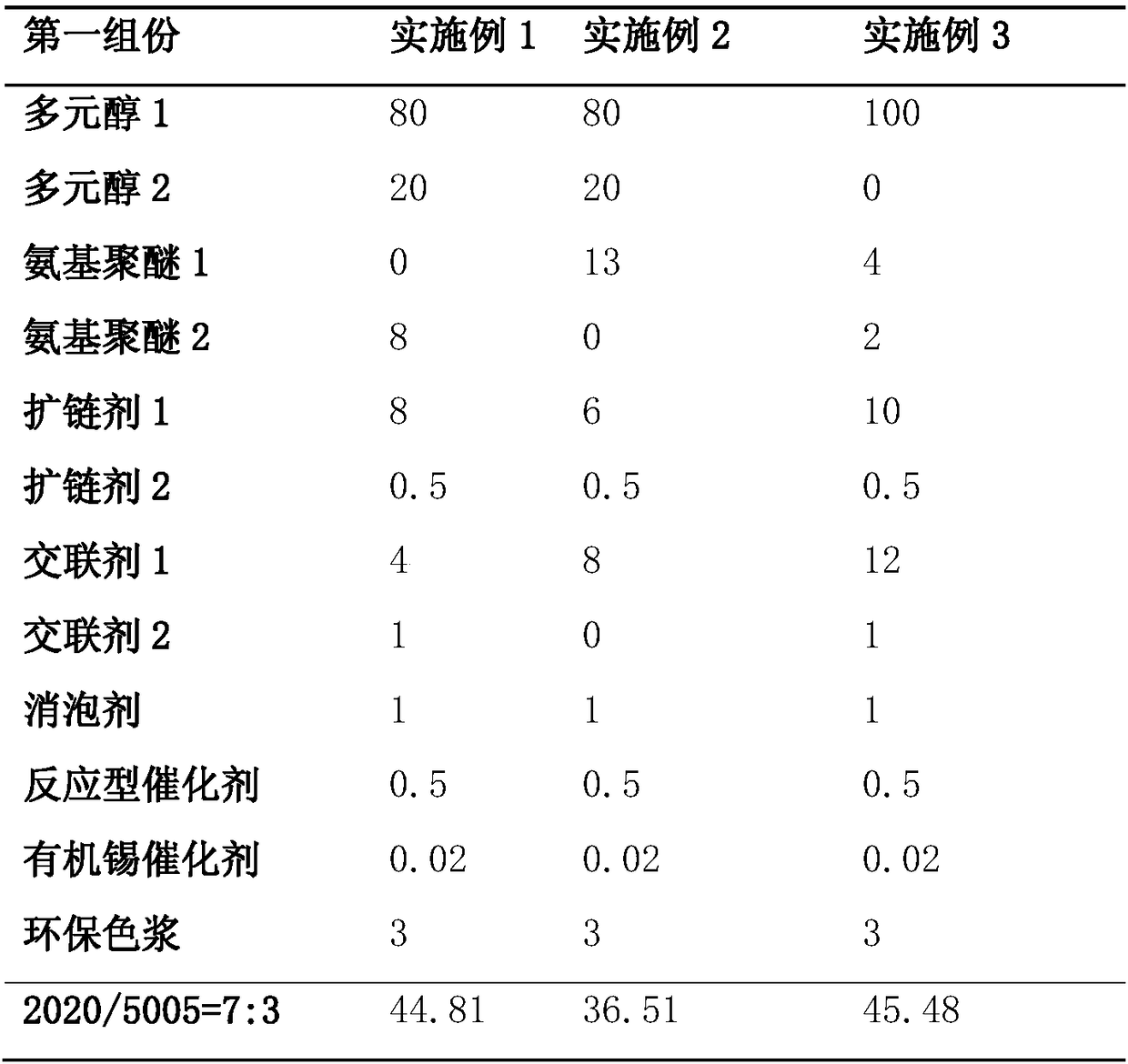

[0078] The formula of table 1 embodiment 1-3

[0079]

[0080] Samples were prepared according to the formulations of Examples 1-3 in Table 1. For each sample, each test was repeated three times, and the average value was obtained.

[0081] The abrasion resistance performance of table 2 embodiment 1-3 abrasion resistance performance

[0082] Example

Example 1

Example 2

Example 3

Dry grinding 100 times

Grade 4‐5

Grade 4‐5

Grade 4‐5

Grade 4‐5

Grade 4‐5

Grade 4‐5

level 4

level 4

level 4

Ammonia Glass Cleaner

Grade 4‐5

Grade 4‐5

Grade 4‐5

Surfactant

Grade 4‐5

Grade 4‐5

Grade 4‐5

[0083] Table 3 embodiment 1-3 solvent resistance performance

[0084]

[0085] The emitting performance of table 4 embodiment 1-3

[0086] Example

Example 1

Example 2

Example 3

Condensed mg

0.49

0.50

0.48

Formal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com