Adhesive for wall cloth and preparation method thereof

An adhesive and adhesive technology, applied in the directions of adhesive additives, adhesive types, starch adhesives, etc., can solve the problems of long drying time of adhesives, pollute the indoor environment, endanger the health of owners, etc., and achieve improvement. The effect of surface drying time, improving drying time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

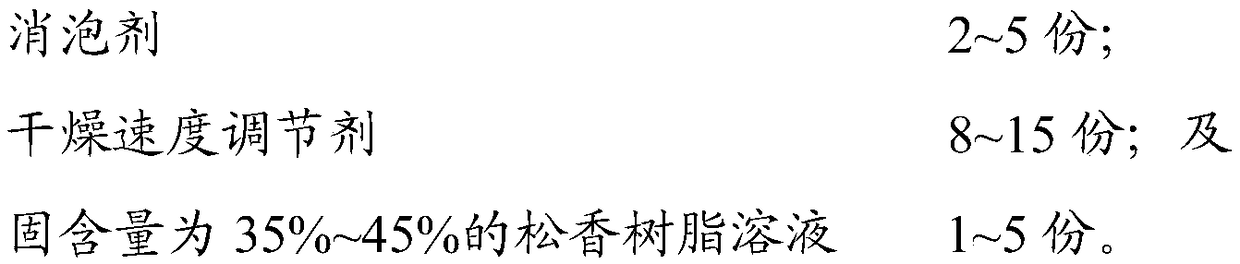

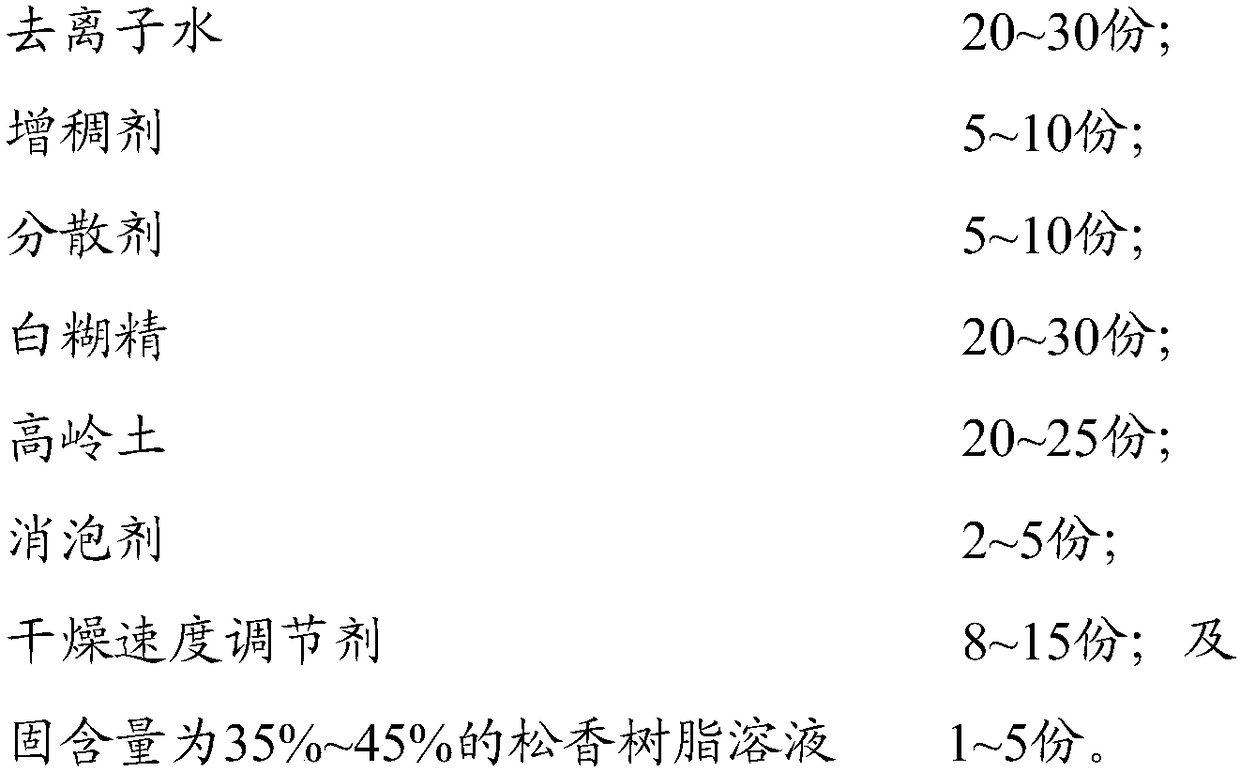

[0036] The invention also discloses a preparation method of the wall covering adhesive. A preparation method for wall covering adhesive, comprising the steps of:

[0037] Mix and stir the deionized water and thickener evenly, then let stand for 20-28h to obtain the premix;

[0038] Add dispersant, white dextrin and kaolin to the premix and stir evenly to obtain a mixture;

[0039] adding the defoamer and the drying speed regulator into the mixture and stirring evenly to obtain the mixture; and

[0040] Add the rosin resin solution into the mixture and stir for 30-60 minutes to obtain the wall cloth adhesive.

[0041] The preparation method of the wall cloth adhesive is simple in process, and the raw materials can be evenly stirred at normal temperature, the production efficiency is high, and the purpose of energy saving and consumption reduction is realized.

[0042] Wherein, the above-mentioned wall covering adhesive may also include 1-5 parts by mass of a fungicide. In t...

Embodiment 1

[0050] The preparation method of the wall covering adhesive of the present embodiment may further comprise the steps:

[0051] (1) Add 20 parts of deionized water and 5 parts of thickener into the first mixing tank in turn, stir evenly, and let stand for 20 hours to obtain the premixed liquid;

[0052] (2) sequentially add 5 parts of dispersant, 20 parts of white dextrin and 20 parts of kaolin to the premixed solution in the above-mentioned first mixing tank, control the speed of the first mixing tank at 200r / min, and stir evenly to obtain the mixed solution;

[0053] (3) Add 2 parts of defoamer and 8 parts of drying speed modifier to the mixed solution in the above-mentioned first mixing tank, control the rotating speed of the first mixing tank at 200r / min, and stir evenly to obtain the mixture; and

[0054] (4) Add 1 part of rosin resin solution with a solid content of 35% to the above-mentioned mixture in the first mixing tank, control the rotation speed of the first mixing...

Embodiment 2

[0058] The preparation method of the wall covering adhesive of the present embodiment may further comprise the steps:

[0059] (1) Add 25 parts of deionized water and 7 parts of thickener into the first mixing tank in turn, stir evenly, and let stand for 24 hours to obtain the premix;

[0060] (2) sequentially add 7 parts of dispersant, 25 parts of white dextrin and 25 parts of kaolin into the premixed liquid in the above-mentioned first mixing tank, control the rotating speed of the first mixing tank at 250r / min, and stir evenly to obtain the mixed solution;

[0061] (3) Add 3 parts of defoamer and 11 parts of drying speed modifier to the mixed solution in the above-mentioned first mixing tank, control the rotating speed of the first mixing tank at 250r / min, and stir evenly to obtain the mixture; and

[0062] (4) Add 3 parts of rosin resin solution with a solid content of 40% to the above-mentioned mixture in the first mixing tank, control the rotation speed of the first mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com