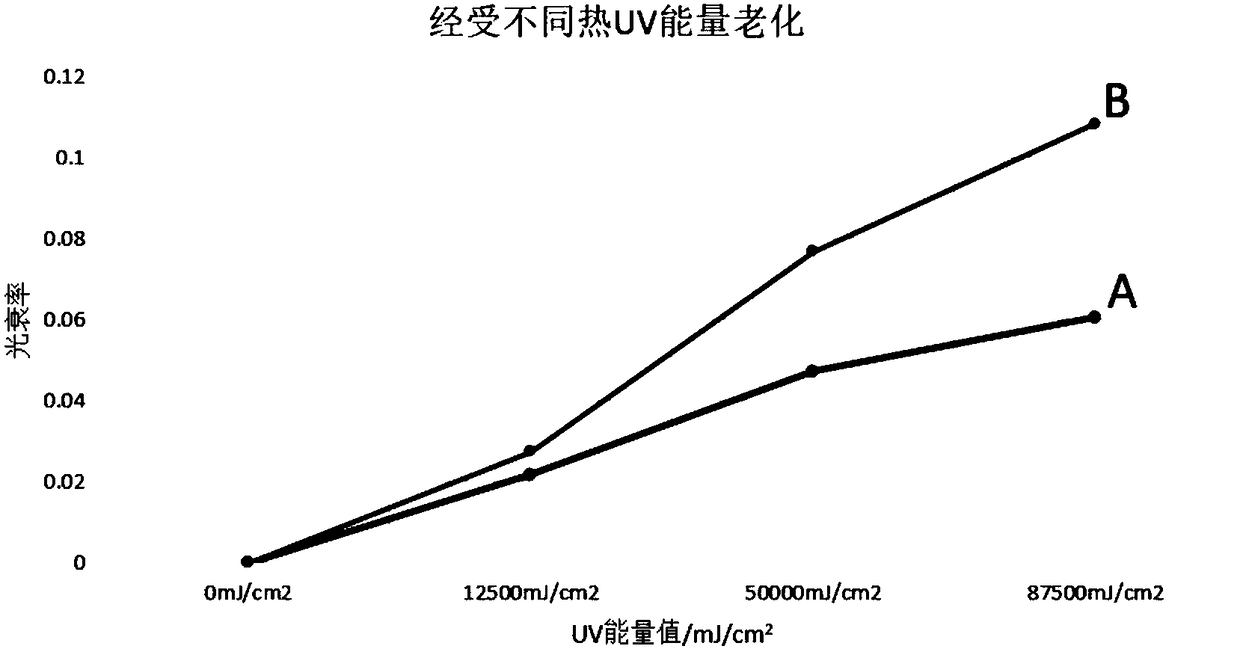

Yellowing resistant bi-component room-temperature curing transparent epoxy glue and preparation method thereof

A room temperature curing, two-component technology, applied in the field of polymer chemistry, can solve the problems of being unable to meet the requirements of outdoor nixie tube potting, poor yellowing resistance, and low time-consuming efficiency, and achieve high resistance to UV aging yellowing, resistance High heat aging yellowing and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The specific scheme is as follows: a preparation method of two-component room temperature curing transparent epoxy adhesive, comprising

[0042] Steps for preparing composition A: Preheat the epoxy resin according to the formula quantity, then add defoaming additives, antioxidants and benzyl alcohol into the preheated epoxy resin according to the formula quantity, mix evenly with a high-speed dispersing mixer, and vacuumize , filtered to obtain composition A;

[0043]Steps for preparing composition B: add epoxy resin anti-yellowing agent into curing agent according to the formula amount, mix evenly with a high-speed dispersing mixer, and filter to obtain composition B;

[0044] Mixing step: when in use, mix the above-mentioned composition A and composition B according to the mass ratio of 2:1.

[0045] In the above preparation method, since the epoxy resin is easily oxidized to generate carbonyl to form a yellowing group, the ability of the antioxidant to decompose the...

Embodiment 1

[0050] A two-component room temperature curing transparent epoxy adhesive is prepared by the following method,

[0051] Steps for preparing composition A: Weigh 88.5g of bisphenol A epoxy resin, preheat at 80°C for 30 minutes, then add 4g of polyphenylene phosphite antioxidant, defoaming copolymer and polysiloxane solvent After mixing 0.5 g and 7 g of benzyl alcohol, they were uniformly dispersed by a high-speed dispersing mixer at 20,000 rpm for 30 minutes, then vacuumed for 10 minutes to break the foam, and filtered through a 160-mesh filter to obtain composition A.

[0052] Steps for preparing composition B: Weigh 99g of modified alicyclic amine curing agent, add 1g of epoxy resin anti-yellowing agent, mix and disperse evenly through a high-speed dispersing mixer at 20,000 rpm for 30 minutes, and pass through a 160-mesh filter Composition B was prepared by filtration.

[0053] Mixing step: when in use, mix the above-mentioned composition A and composition B according to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com