Hydraulic floating power balance brake

A brake and booster technology, applied in the direction of brake types, drum brakes, mechanical equipment, etc., can solve the problems of poor braking performance, braking fading, braking efficiency and heat dissipation of unbalanced brakes, etc., and achieve practical operation Strong performance, improved braking performance, and good stability in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

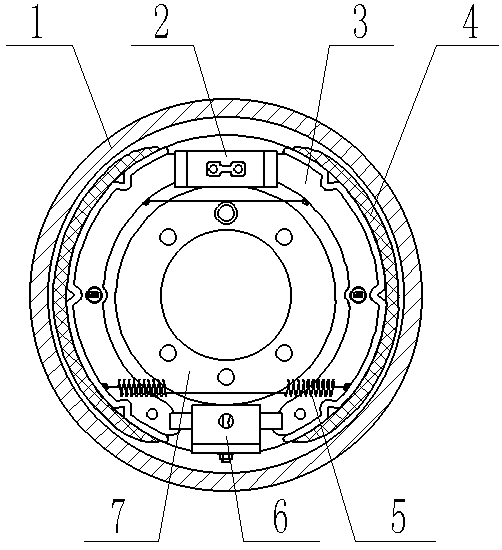

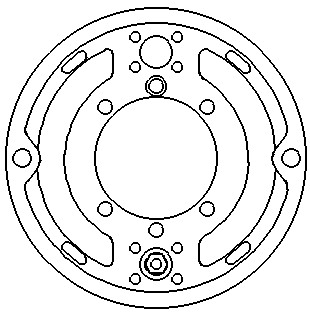

[0052] As shown in the accompanying drawings of the specification, a hydraulic floating booster balance brake includes a brake drum 1, a brake bottom plate 7, a hydraulic cylinder 2 and a brake shoe 3, and the brake drum 1 is provided with a brake shoe 3 and the hydraulic cylinder 2, and the brake shoe 3 is arranged along the inner side of the brake drum 1; the hydraulic cylinder 2 and the brake shoe 3 are both arranged on the brake bottom plate 7, and the brake shoe 3 is provided with a friction plate 4; The booster balance brake is also provided with a booster balance mechanism 6; the booster balance mechanism 6 is symmetrically arranged on the brake base plate 7 with the hydraulic cylinder 2; the brake shoes 3 are provided with two, respectively Arranged on both sides of the brake base plate 7, one end of the two brake shoes is connected with the hydraulic cylinder 2, and the other end is connected with the booster balance mechanism 6, that is, the hydraulic cylinder 3 and t...

Embodiment 2

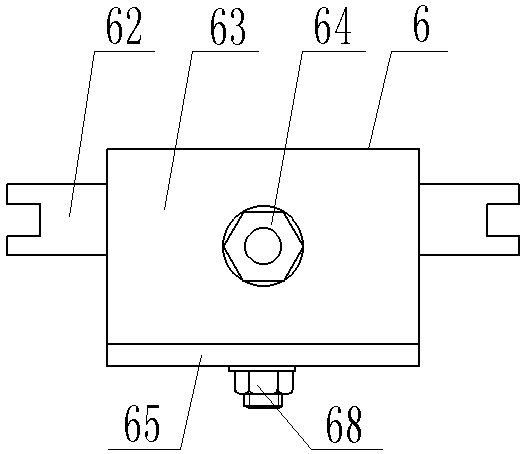

[0055] As shown in the accompanying drawings of the description, based on the hydraulic floating booster balance brake of Embodiment 1, the main board 61 is also provided with a side through hole 611, a groove 1 612, a deep groove 613 and a threaded hole 614; the side through hole 611 It is horizontally arranged in the main board 61 along the opening and closing direction of the brake shoes 3; a connecting mechanism is provided in the side through hole 611 for connecting the main board 61 and the brake shoes 3. The first groove 612, the deep groove 613 and the threaded hole 614 are all designed on the bottom surface of the main board 61; the first groove 612 is arranged in parallel with the deep groove 613, and the deep groove 613 and the threaded hole 614 are on the same horizontal line; The through hole 611 is arranged in parallel above the groove one 612; the top plate mechanism 67 is arranged in the deep groove 613; the spring one 66 is arranged in the groove one 612. The ...

Embodiment 3

[0057] Such as Figure 7 As shown, based on the hydraulic finishing balance brake described in Embodiment 2, a top plate mechanism 67 includes a spring sleeve 671 and a second spring 672; one end of the second spring 672 extends into the deep groove 613 on the main board 61, and the other end Stretch into the spring sleeve 671; the shape and size of the spring sleeve 671 are consistent with the size of the deep groove 613, and the inner diameter of the spring sleeve 671 is equal to the diameter of the spring two 672; In the spherical groove 652 on the plate 65; the spherical surface of the top of the spring sleeve 671 is smaller than the spherical surface of the spherical groove 652.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com